PCB 1102-04A User manual

Model 1102-04A

Strain Gage Load Cell

Installation and Operating Manual

For assistance with the operation of this product,contact:

PCB Load & Torque, Inc.

Toll-free: 866-684-7107

24-hour SensorLine™: 716-684-0001

Fax: 248-888-8266

Web: www.pcbLoadTorque.com

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Total Customer Satisfaction –PCB

Piezotronics guarantees Total Customer

Satisfaction. If, at any time, for any

reason, you are not completely satisfied

with any PCB product, PCB will repair,

replace, or exchange it at no charge.

You may also choose to have your

purchase price refunded in lieu of the

repair, replacement, or exchange of the

product.

Service –Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to insure that liquids are not permitted to

migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair –In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration –Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO-

9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment –Following

these procedures will insure that your

returned materials are handled in the

most expedient manner. Before

Warranty, Service, Repair, and

Return Policies and Instructions

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Warranty –All equipment and repair

services provided by PCB Piezotronics,

Inc. are covered by a limited warranty

against defective material and

workmanship for a period of one year

from date of original purchase. Contact

PCB for a complete statement of our

warranty. Expendable items, such as

batteries and mounting hardware, are

not covered by warranty. Mechanical

damage to equipment due to improper

use is not covered by warranty.

Electronic circuitry failure caused by the

introduction of unregulated or improper

excitation power or electrostatic

discharge is not covered by warranty.

Contact Information –International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅(Pb)

汞

(Hg)

镉

(Cd)

六价铬(Cr(VI))

多溴联苯 (PBB)

多溴二苯醚(PBDE)

住房

O

O

O

O

O

O

PCB板

X

O

O

O

O

O

电气连接器

O

O

O

O

O

O

压电晶体

X

O

O

O

O

O

环氧

O

O

O

O

O

O

铁氟龙

O

O

O

O

O

O

电子

O

O

O

O

O

O

厚膜基板

O

O

X

O

O

O

电线

O

O

O

O

O

O

电缆

X

O

O

O

O

O

塑料

O

O

O

O

O

O

焊接

X

O

O

O

O

O

铜合金/黄铜

X

O

O

O

O

O

本表格依据 SJ/T 11364 的规定编制。

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: C

ECN: 45605

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing

O

O

O

O

O

O

PCB Board

X

O

O

O

O

O

Electrical

Connectors

O

O

O

O

O

O

Piezoelectric

Crystals

X

O

O

O

O

O

Epoxy

O

O

O

O

O

O

Teflon

O

O

O

O

O

O

Electronics

O

O

O

O

O

O

Thick Film

Substrate

O

O

X

O

O

O

Wires

O

O

O

O

O

O

Cables

X

O

O

O

O

O

Plastic

O

O

O

O

O

O

Solder

X

O

O

O

O

O

Copper Alloy/Brass

X

O

O

O

O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

CANISTER LOAD CELL OPERATION MANUAL

1

TABLE OF CONTENTS

1.0 INTRODUCTION..................................................................................................................2

2.0 SAFETY PRECAUTIONS....................................................................................................2

3.0 OVERVIEW..........................................................................................................................2

3.1 Dimensions .......................................................................................................................................2

3.2 Optional Components .......................................................................................................................2

4.0 MECHANICAL INSTALLATION..........................................................................................2

5.0 ELECTRICAL INSTALLATION ...........................................................................................3

5.1 Electrical Drawing / Western Regional Std.......................................................................................3

5.2 Output Polarity ..................................................................................................................................3

5.3 Cable & Grounding Considerations ..................................................................................................3

6.0 CALIBRATION.....................................................................................................................3

6.1 Calibration Certificate Description.....................................................................................................3

6.1.1 Measured Output.....................................................................................................................4

6.1.2 Hysteresis................................................................................................................................4

6.1.3 Best Fit Output........................................................................................................................4

6.1.4 Strain Gage Measurements .....................................................................................................4

6.1.5 Shunt Calibration Standard Resistor.......................................................................................4

6.1.6 Static Error Band (SEB)..........................................................................................................4

7.0 SHUNT CALIBRATION DESCRIPTION..............................................................................4

7.1 Resistor Value...................................................................................................................................4

7.2 Shunt Calibration Process.................................................................................................................4

7.3 Estimating Shunt Resistor for a Given Load.....................................................................................4

8.0 MAINTENANCE...................................................................................................................5

9.0 TROUBLESHOOTING.........................................................................................................5

9.1 Mechanical Troubleshooting.............................................................................................................5

9.2 Electrical Troubleshooting.................................................................................................................5

10.0 CALIBRATION / REPAIR SERVICES...............................................................................5

10.1 RMA / Purchase Order....................................................................................................................5

11.0 WARRANTY ......................................................................................................................5

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

CANISTER LOAD CELL OPERATION MANUAL

2

1.0 INTRODUCTION

General purpose canister load cells manufactured by PCB

Load & Torque are suitable for a wide range of general force

measurement applications, including weighing, dynamometer

use, and static material test machines. These load cells

operate in tension and compression. Standard 1/4”-28 female

threads facilitate ease of installation.

The following document explains the characteristics and

installation of the canister load cells.

2.0 SAFETY PRECAUTIONS

Failure of the load cell structure may cause personal injury

and equipment damage.

The load cell can withstand loads of at least 150% of the full-

scale capacity before any damage occurs to the sensing

element. Be sure that the load cell and any fixturing used is

properly designed, fabricated, and securely installed prior to

use.

3.0 OVERVIEW

Canister load cells come in a variety of capacities to handle

loads ranging from 25 lbf to 300 lbf.

3.1 Dimensions

3.2 Optional Components

4.0 MECHANICAL INSTALLATION

Loads applied to canister load cells must be even and centered.

Compensation linkages (e.g. rod end bearing, alignment

couplers) are recommended to help minimize load

misalignment. When installing fixtures, be sure to thread the

fixture to the load cell, and not the load cell to the fixture. If

alignment fixtures are not used, ensure loading surfaces are

flat and parallel, with loads applied in-line with the sensor.

Figure 2 - Dimensions

Table 2 - Dimension Values

Table 1 - Full-Scale Capacities

Figure 1 – Canister Load Cell Loading

Full

-

Scale Capacities

Model

(lbf)

(N)

1102

-

05A

25 110

1102

-

01A

50 222

1102

-

02A

100 445

1102

-

03A

200 900

1102

-

04A

300 1334

M1102

-

05A

28 125

M1102

-

01A

56 250

M1102

-

02A

112 500

M1102

-

03A

225 1000

M1102

-

04A

337 1500

Dimensions

(see Figure 2)

Series Number

1102 M1102

(in) (mm) (in) (mm)

1

∅

2.75

∅

69.9

∅

2.75

∅

69.9

2

∅

0.44

∅

11.2

∅

0.44

∅

11.2

3

∅

1.75

∅

44.5

∅

1.75

∅

44.5

4

1.50 38.1 1.50 38.1

5

0.09 2.3 0.09 2.3

6

0.06 1.5 0.06 1.5

7

3.17

80.5

3.17

80.5

8

¼”-28 Tapped M6x1.0 Tapped

9

¼”-28 Tapped M6x1.0 Tapped

4

5

7

9 3

2 1

8

6

Tensile Load

Tensile Load

Compression

Load

Compression Load

Item Number

Descript

ion

181-012A PT06A-10-6S (SR), Mating Connector

8311-01-10A Cable – Non-Coax, PT65 to Pigtail, 10 feet

Table 3 - Optional Components

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

CANISTER LOAD CELL OPERATION MANUAL

3

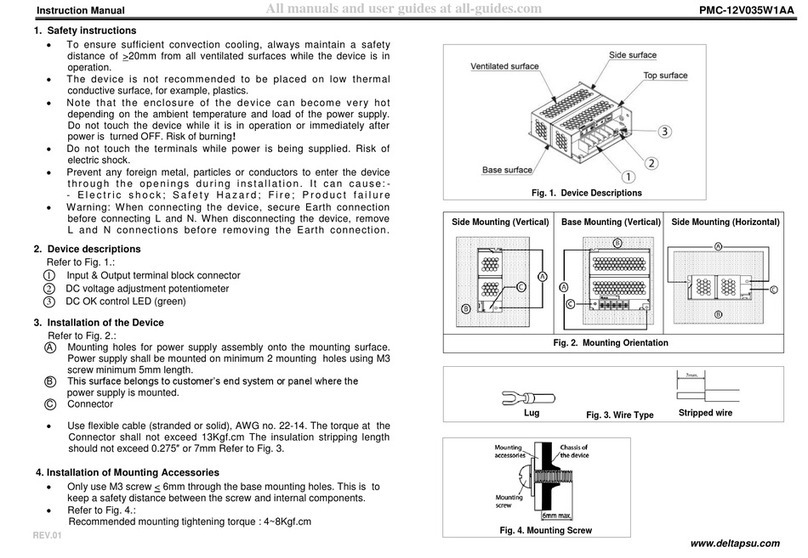

5.0 ELECTRICAL INSTALLATION

5.1 Electrical Drawing / Western Regional Std.

All load cells are wired following the Western Region

Standard. All models utilize strain gages configured into a

Wheatstone Bridge Circuit to produce the primary sensing

element. The four-arm Wheatstone bridge configuration is

shown below in Figure 3.

The gages are bonded to the load cell's structure.

Typically, a regulated DC or AC excitation is applied

between A and D of the bridge. When a force is applied to

the load cell, the Wheatstone bridge becomes unbalanced,

causing an output voltage between B and C, which is

proportional to the applied load. This configuration allows

for temperature and pressure compensation, as well as

cancellation of signals caused by forces not directly

applied to the axis of the applied load. Output is typically

expressed in units of mV/V of excitation.

5.2 Output Polarity

The following figure describes the output polarity.

5.3 Cable & Grounding Considerations

Proper grounding and shielding is required to prevent

electrical noise in strain gage load cell measuring systems.

The cable must be shielded twisted pairs with a drain wire.

Cable shields must be grounded only at one end, for example,

on the instrument or control system ground. The load cell

case is grounded by mechanical attachment to the structure to

which it is mounted.

The instrument or control system is grounded through its

power cord. Ground loops and measuring system wiring may

result in unstable or noisy signals.

A simple test with a voltmeter connected between the power

cord ground and the structure on which the load cell is

mounted can confirm that the structure has been properly

grounded. If the power cord ground and structure ground are

not at the same potential, it may be necessary to provide a

secure structure ground, perhaps by driving a copper rod and

attaching a ground strap.

6.0 CALIBRATION

Every canister load cell manufactured by PCB Load & Torque

has been fully calibrated per ISO/IEC 17025 procedures, and

meets all published specifications. Each load cell will come

with a calibration certificate designated with matching model

and serial numbers. PCB Load & Torque also offers

calibration services on an on-going basis.

6.1 Calibration Certificate Description

Calibration reports supplied with canister load cells contain

valuable information to assist the customer in use of the

equipment. A separate calibration report is provided for

tension and compression calibrations. Calibration procedures,

equipment, and reports comply with ISO/IEC 17025.

Table 4 - Electrical Connections

Figure 5 - Grounding

Test Rig Ground

Power Supply

Instrument Ground

Cable Shielding

Load Cell

C

A

D

B

- Signal White

- Excitation Black

+ Excitation Red

+ Signal Green

Figure 3 - Western Regional Strain Gage Committee Wiring Code

Figure 4 - Output Polarity

Load Cell Receptacle: PT02E-10-6P

Mating Connector: PT02A-10-6S

PCB Load & Torque P/N: 181-012A

Tensile Load

= Positive

Tensile Load

= Positive

Compression Load

= Negative

Compress

ion Load

= Negative

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

CANISTER LOAD CELL OPERATION MANUAL

4

6.1.1 Measured Output

The applied load starting at zero is measured in five

increments to full scale. Output (mV/V) is measured at each

increment. The straight-line from zero to the full scale

measurement is compared to the measured readings at each

increment to calculate the error at each load increment. The

deviations (% Full Scale) corresponding to non-linearity at

each measurement increment are then calculated.

6.1.2 Hysteresis

The difference between the ascending and descending

measured readings at 40% of full scale is used to calculate the

hysteresis value.

6.1.3 Best Fit Output

The best fit calibration second-order equation has been

calculated from the calibration data by the method of least

squares. Deviation between measured output and best-fit

output is calculated and displayed in the column next to the

best-fit output for each measurement increment. The

deviations (% Full Scale) of measured outputs from the

calculated best fit are tabulated for each measured reading.

6.1.4 Strain Gage Measurements

6.1.5 Shunt Calibration Standard Resistor

All canister load cell calibrations use a 120K Ohm (0.1%)

precision resistor shunt calibration value that is supplied into

the calibration report.

6.1.6 Static Error Band (SEB)

The static error band (SEB) is determined by the maximum

deviations of the ascending and descending calibration points

from the best fit straight line through zero output. The SEB

includes the effects of nonlinearity, hysteresis, and non-return

to minimum load.

7.0 SHUNT CALIBRATION DESCRIPTION

Shunt calibration is used to simulate a known tension or

compression load on a load cell. The calibration certificate

will indicate which leg of the bridge to apply the shunt resistor

to for both tension and compression load simulation. Typically

tension is simulated by inserting the shunt resistor between the

+P and +S connector leads. Compression loading is simulated

by inserting the shunt resistor between the +S and –P

connector leads.

7.1 Resistor Value

Canister load cells have a nominal 2.0 mV/V full scale output.

For a 700 ohm strain gage bridge the precision shunt resistor,

120,000 ohms ±0.1%, simulates an output of approximately

73% of the full scale output for the load cell. The calibration

values for each bridge are found on the calibration certificates

supplied with each load cell.

7.2 Shunt Calibration Process

To perform the shunt calibration, use the following procedure:

1. Stabilize all forces on the load cell. If possible,

remove all loads.

2. Power up the host signal conditioner and connect it to

the load cell via appropriate cable, and allow for a 30

minute warm up.

3. Set the load indicator display to read exactly 00.000.

4. Connect the shunt resistor to the terminals specified

in the calibration certificate, and adjust the span or

gain until the display reads the force value stated on

the certificate.

5. Repeat steps 1-3 to verify that a valid calibration

setting has been obtained.

6. If possible, apply a known load to the measurement

system to further verify that the calibration has been

accurately set up.

7.3 Estimating Shunt Resistor for a Given Load

The following formula can be used to estimate the

approximate value of shunt resistor required to simulate a

mechanical load.

R

cal

= (25 * R

b

) / (Output

FS

* L

cal

)

Where: R

cal

= Shunt Resistor (K ohms)

R

b

= Bridge Resistance (ohms)

Output

FS

= Full Scale output of the load cell (mV/V)

L

cal

= Load to be simulated, % of Load Cell Capacity

Bridge Resistance: 700 Ohm Nominal

Excitation: +P(A) to –P(D) Ohms

Signals: +S(B) to –S(C) Ohms

Leakage to Ground: > 5k GOhm

Bridge Unbalance: ±1.0% Full Scale

Output: 2.0 mV/V Nominal

Maximum Voltage: 20 VDC

Table 5 – Strain Gage Measurements

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

CANISTER LOAD CELL OPERATION MANUAL

5

8.0 MAINTENANCE

Routine maintenance of the canister style load cell should

include cleaning the electrical connectors, housings, and

mounting surfaces with solutions and techniques that will not

harm the physical material of construction. Make sure liquids

are not allowed to migrate into devices that are not

hermetically sealed. Such devices should only be wiped with

a damp cloth, and never be submerged or have liquids poured

on them. Never use a pressure washer on the load cells.

Yearly calibrations are recommended to ensure that the unit’s

outputs match the factory specifications.

9.0 TROUBLESHOOTING

Proper performance of a load cell requires careful attention to

both electrical and mechanical aspects of the measurement

system. A basic understanding of the electrical and

mechanical installation requirements is recommended.

9.1 Mechanical Troubleshooting

A mechanical checklist includes:

1. Check for proper installation of fixturing.

2. Check integrity of the fixturing.

9.2 Electrical Troubleshooting

An electrical checklist should start with:

1. Check cables for proper wiring and make sure

connections are secure and proper.

2. Inspect for loose or dirty electrical connections.

3. Check for improper shield grounds.

4. Check for proper grounding of the structure that the

load cell is mounted on.

5. Check the signal conditioning electronics for proper

setup.

6. Check the insulation resistance of shielded

conductors for short circuits.

7. Check isolation resistance, load cell flexure to

conductors.

8. Check load cell bridge resistances, (A-D) excitation

and (B-C) the signal leads.

9. Check bridge balance.

10. Keep a record of your observations, correct problems,

or contact PCB factory for assistance.

10.0 CALIBRATION / REPAIR SERVICES

PCB Load & Torque offers calibration and repair services.

The PCB Calibration Laboratory in Farmington Hills,

Michigan is A2LA Accredited per ISO/IEC 17025.

Standard calibration certificates list five force points

ascending and one point descending. Additional data points

are available at extra cost upon request. A 60 K ohm (±0.1%)

shunt calibration resistor is supplied with each load cell

calibration.

Certificate information includes tabulated measurement

variable data zero balance, bridge input/output resistance,

computer nonlinearity and hysteresis, static error band (SEB)

calculations and entries abilities and traceability statements.

If an initial evaluation shows that a transducer requires repair,

PCB will provide the customer with an estimate prior to taking

any corrective action.

10.1 RMA / Purchase Order

Please request a return material authorization (RMA) before

sending a load cell back to the factory for any reason. For

calibration services, if possible, a copy of the purchase order

covering the requested services should be included with the

returned load cell.

11.0 WARRANTY

Standard warranty on canister style load cells covers parts and

workmanship. For full details, refer to the Warranty

Statement supplied with each load cell.

If the load cell is defective for reasons other than overloads,

return it to the factory for detailed evaluation. Factory

evaluation may show that the load cell is repairable or non-

repairable and if repair or replacement will be under warranty.

If not under warranty, acost of repairs and recalibration will

be provided. Once authorization to proceed is received, a

delivery date will be provided.

Manual Number: 56337

Manual Revision: A

Revision Date: 5/19/15

ECO Number: 44231

Model Number

1102-04A STRAIN GAGE LOAD CELL Revision: H

ECN #: 43815

Performance ENGLISH SI

Measurement Range 300 lb 1334 N [5

Sensitivity(± 10 %) 2 mV/V 2 mV/V [6

Non-Linearity ≤ 0.05 % FS ≤ 0.05 % FS

Hysteresis ≤ 0.05 % FS ≤ 0.05 % FS

Non-Repeatability ≤ 0.02 % FS ≤ 0.02 % FS

Eccentric Load Sensitivity ≤ .25 %/in ≤ .25 %/25.4mm

Resonant Frequency 7.0 kHz 7.0 kHz

Creep(in 20 minutes) ≤ .025 % ≤ .025 %

Static Error Band ≤ .05 % FS ≤ .05 % FS

Environmental

Overload Limit 450 lb 2000 N

Load Limit(Side Force, FX or FY) 300 lb 1334 N [3

Load Limit(Bending Moment, MX or MY) 300 in-lb 34 Nm [3

Load Limit(Axial Torque, MZ) 65 in-lb 7 Nm [3

Temperature Range(Operating) -65 to +200 °F -54 to +93 °C

Temperature Range(Compensated) +70 to +170 °F +21 to +77 °C

Temperature Effect on Output(Maximum) ± 0.0015 %Reading/°F ± 0.0027 %Reading/°C [4

Temperature Effect on Zero Balance(Maximum) ± 0.0008 %FS/°F ± 0.0015 %FS/°C [4

Electrical

Bridge Resistance 700 Ohm 700 Ohm [1

Excitation Voltage(Recommended) 10 VDC 10 VDC [2

Insulation Resistance >5x109 Ohm >5x109 Ohm

Zero Balance ≤ 1 % FS ≤ 1 % FS

Output Polarity +Tension +Tension

Physical

Size (Diameter x Height) 2.75 in x 1.5 in 69.9 mm x 38.1 mm [7

Weight 0.67 lb 304 g

Mounting Thread 1/4-28 Female No Metric Equivalent

Housing Material Painted Aluminum Painted Aluminum

Sensing Element Strain Gage Strain Gage

Deflection at Full Scale Capacity 0.003 in 0.08 mm

Electrical Connector PT02E-10-6P PT02E-10-6P

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

NOTES:

[1 Nominal.

[2 Calibrated at 10 VDC, usable 5 to 20 VDC or VAC RMS.

[3 Singularly applied, i.e. no other extraneous loads.

[4 Over compensated operating temperature range.

[5 FS - Full Scale.

[6 RO - Rated Output.

[7 See Outline Drawing 51277 for Complete Dimensions

OPTIONAL ACCESSORIES:

Model 181-012A PT06A-10-6S(SR)

Model 8311-01-10A CABLE

PCB Load & Torque, Inc.

24350 Indoplex Circle

armington Hills, MI 48335

UNITED STATES

Phone: 866-684-7107

ax: 716-684-0987

E-Mail: ltinfo@pcbloadtorque.com

Web site:

http://www.pcbloadtorque.com

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard

model except where noted below. More than one option may be used.

Entered: AP Engineer: PE Sales: JC Approved: JSD Spec Number:

Date: 2/17/2015 Date: 2/17/2015 Date: 2/17/2015 Date: 2/17/2015 18330

PIN A + EXC

PIN B

+SIG

PIN C

-SIG

PIN D -EXC

PIN E N/C

PIN F

N/C

WIRING CODE

1

1

2

2

3

3

4

4

A A

B B

DWG. NO.

SCALE: SHEET

DRAWN CHECKED ENGINEER

TITLE

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

ANGLES

`

.5 DEGREES

24350 Ind plex Circle, Farmingt n Hills,MI 48335

(716) 684-0001 E-MAIL: ltinf @pcbl adt rque.c m

DIMENSIONS IN INCHES

ANGLES

`

.5 DEGREES

FILLETS AND RADII

.015 MAX

FILLETS AND RADII

0.38 MAX

OUTLINE DRAWING

51277

1 OF 1FULL

1102 SERIES, PT CONN.

CANNISTER LOAD CELL

PTE /14/11

DECIMALS XX ±.01

XXX ±.005

DECIMALS X ± 0.3

XX ± 0.13

51277

PCB L ad & T rque Inc. claims pr prietary rights in

the inf rmati n discl sed here n. Neither it n r any

repr ducti n there f will be discl sed t thers with ut

the written c nsent f PCB L ad and T rque Inc.

REVISIONS

REV DESCRIPTION ECO

AADDED NOTE 1, WIRING CODE 38165

PT02E-10-6P RECEPTACLE

"THREAD"

x

.38 [9.6]

(STANDARD LOAD CELLS 1/4-28UNF-2B,

METRIC LOAD CELLS M6X1.0 6H)

.44 [11.2]Ø

2.75 [69.9]Ø

n

1.75 [44.5]

.86 [21.9]

1.34 [34.0]

.10 [2.5]

1.50 [38.1]

1.82 [46.2]

"THREAD"

x

.38 [9.6]

(STANDARD LOAD CELLS 1/4-28UNF-2B,

METRIC LOAD CELLS M6X1.0 6H)

JDM 01.08.12 ECB 01.0 .12

This manual suits for next models

1

Table of contents

Other PCB Power Supply manuals

Popular Power Supply manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI NLG13D724SA user manual

Pulsar

Pulsar POE1648 manual

Rockwell Automation

Rockwell Automation 1606-XLS180B instruction manual

UV-technik

UV-technik EVG UVT 2x 100-200 W operating manual

illuburg

illuburg ST-25M-DALI2 Datasheet and Operating Instructions

Horizont

Horizont hotshock ABN37 instruction manual

B+K precision

B+K precision 1715A instruction manual

ARTESYN EMBEDDED TECHNOLOGIES

ARTESYN EMBEDDED TECHNOLOGIES ATCA-7180 quick start guide

TREX

TREX Fuel tank chameleon manual

I-Tech

I-Tech IT6500 Series Programming guide

Alarm SAF

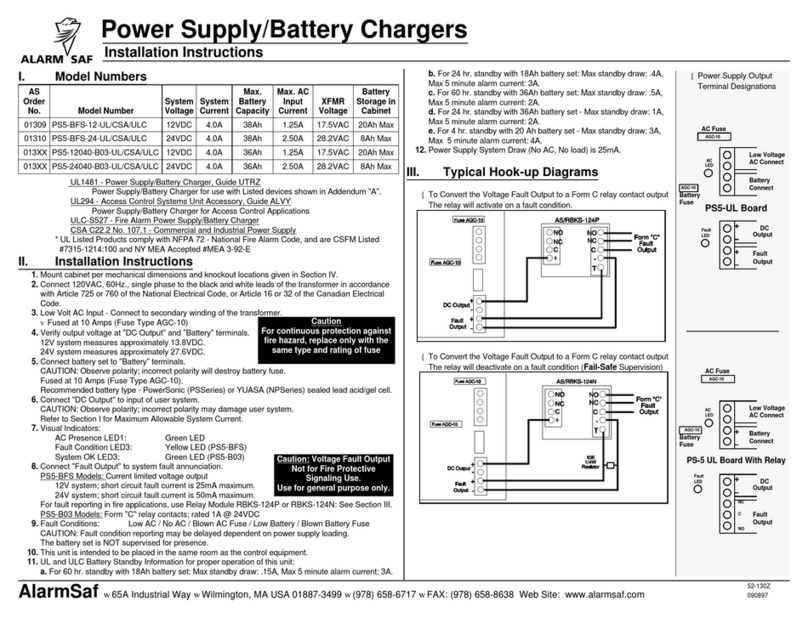

Alarm SAF PS5-BFS-12-UL installation instructions

B+K precision

B+K precision 1698 instruction manual