PCC D3400 Service manual

MODEL NO. V

~£f22-

MODELS

03300

AND

D3400

DISK

DRIVES

-_

.....

PSlTEC

COmpUT'EA

.....

_

COAPOAATlOn

PERTEC

DIVISION

9600 IRONDALEAVENUE, CHATSWORTH, CA91311

OPERATING AND SERVICE

MANUAL

NO. 104630

'2;

1978 by Partee

Computer

Corporation

__

O.

o-nber1978

FOREWORD

This manual provides operating

and

service instructions for the 03000 Series Disk Drives

Models 03300

and

03400, manufactured

by

the Pertec Division of Pertec Computer

Corporation, Chatsworth,

Cal

iforn

ia.

The

content includes a detailed description, specifications, installation instructions,

and

checkout of the disk drive. Also included

are

theory of operation

and

preventive

maintenance instructions. Section

VII

contains a recommended spare parts list, photo

parts Iists and schematics.

All graphic symbols used in logic diagrams conform to the requirements of

ANSI

Y32.14

and

all symbols used in schematic diagrams

are

as

specified in Y32.2.

The

disk drive models covered

by

this manual

are

listed below.

Cartridge

Type Load

Model

Tracks per

Inch

Bits

per

Inch

Fixed Disk

Spindle

Speed (rpm)

Front

Top

D331

X 100 2200 X 1500

or

2400

D332X 100 2200 X X 1500

or

2400

D334X 100 2200 X X 1500

or

2400

D342X 200 2200 X X 1500

or

2400

D344X 200 2200 X X 1500

or

2400

ii

SERVICE AND WARRANTY

This Pertec Computer Corporation

(PCC)

product has been rigorously checked out by capable Quality control personnel. The design

has been engineered with a precise simplicity which should assure a new level

of

reliability. Ease

of

maintenance has been taken

into

consideration during the design phase with the result that all components (other than mecnanical components) have been

selected wherever possible from manufacturer's off·the-shelf stock. Should a component fail, it may be readily replaced from

PCC

Peripherals Division

or

your local supplier. The unit has been designed for plug·in replacement

of

circuit boards

or

major

components which will ensure a minimum

of

eQuipment down time.

The

Peripherals Division

of

PCC

warrants products of its manufacture to

be

free from defect in design, workmanship,

and

material

under normal use and service for a period twelve

(12)

months,

or

in the case of flexible disk products

120

days, after the date

of

shipment.

PCC

Peripherals DiviSion agrees to repair

or

replace at

its

authorized repair center, without charge, all defective parts in

systems which are returned for Inspection to said center within the applicable warranty period; provided such inspection discloses that

the defects are

as

specified above, and provided further the equipment has not been altered

or

repaired other than with authorization

from

PCC

Peripherals Division and by its approved procedures, not been subjected to misuse, improper maintenance, negligence

or

accident, damaged

by

excessive current orotherwise

had

its

serial number

or

any part thereof altered, defaced

or

removed. All defective

items released hereunder shall become the property

of

seller. THIS WARRANTY

IS

IN

LIEU

OF,

AND

BUYER

WAIVES, ALL

OTHER

WARRANTIES,

EXPRESSED

OR

IMPLIED, INCLUDING

THOSE

OF MERCHANTABILITY

OR

FITNESS

FOR

PURPOSE.

Please

read

the instruction manual thoroughly as

to

installation, operation, maintenance, and component reference list.

Contact your local PeC Service Division office for serviCing and maintenance on all

PCC

equipment except flexible

disk

drives.

Flexible disk drives must be returned to the Peripherals Division factory Repair Depot for servicing.

Please contact the following groups for assistance with your specific problem.

SERVICE DIVISION SUPPORT

For all servicing reQuirements on

PCC

Peripherals Division equipment, please contact your local PeC Service Division office.

Additionally, the Service Division offers maintenance contracts, service contracts, third party maintenance contracts, etc.

PERIPHERALS DIVISION SUPPORT

NORTH AMERICA:

21111

Erwin Street, Woodland Hills, California

91367,

(213)

999-2020

Our Woodland Hills facility is staffed to provide assistance in the following areas.

ORDER

ADMINISTRATION

• For submitting your equipment orders.

• For obtaining delivery schedules on your equipment.

• For any other information on your orders. (Note also that

your local sales office can answer these questions.)

TRAINING SUPPORT

• Contact the Training Coordinator for class schedules, for

classes

to

be

held at your facilities, or for having a

customized training program developed.

SPARES

SUPPORT

• Spares Order Administration for submitting your spare

requests (except Emergency).

• Spares Logistics Administrators to answer any Questions

on spares (including assistance in determining part

numbers).

NORTH AMERICA:

9600

Irondale Avenue, Chatsworth, California

91311,

(213)

882-0030

Our Chatsworth facilities are staffed to provide aSSistance in the following areas.

REPAIR

DEPOT

• For all Questions related to eQuipment sent back or being

sent back to the Repair Depot. This includes schedules,

repair costs, or refurbishments.

• All eQuipment being returned for repair should

be

sent

to

PCC

Peripherals Division Repair Depot,

20400

Plummer

Street, Chatsworth, California,

91311.

TECHNICAL

SUPPORT

• For eQuipment troubleshooting assistance.

• For applications information.

• For any other information or questions, or if you need

assistance and you just

don't

know who

to

call.

EMERGENCY

SPARES

• For spare parts that are reQuired immediately.

EUROPE:

10

Portman Road, Reading, Berkshire

RG3

1DU.

England

Phone Reading

(734)

5821151

TWX

(851)

847·101

Users

of

PCC

Peripherals Division equipment in Europe should direct all inquires on the subjects listed for North America to the

Reading office.

ServiCing

of

all

PCC

Peripherals Division equipment is coordinated through the Reading office, including

U.S.

OEMs that ship

systems to Europe. PACIFIC

Users of

PCC

Peripherals Division equipment in Australia, Japan, New Zealand, and South America should direct all inQuiries

on

the

sub;ects listed for North America to their local pce representatives.

iii

6179

/

PROPRIETARY NOTICE

Information contained

in

this document

is

copyright by Pertec Computer

Corporation and may not be duplicated

in

full

or

in part by any person

without

prior written approval

of

Pertec Computer Corporation. Its purpose is to

provide the User with adequately detailed documentation so as to

efficiently

install, operate, maintain, and order spare parts

for

the equipment supplied.

Every

effort

has been made to keep the information contained in this

document current and accurate

as

of the date of publication or revision.

However, no guarantee is given or implied that the document is error-free

or

that

it

is

accurate with regard to any specification_

iv

TABLE

OF

CONTENTS

SECTION

I - GENERAL DESCRIPTION AND SPECIFICATIONS

1.1

Introduction

.....................................................

1-1

1.1.1 Model Identification

...............

"

......................

1-1

1.2 Purpose of Equipment

............................................

1-2

1.3 Physical Description of Equipment

.................................

1-2

1.4 Functional Description

............................................

1-3

1.5 Mechanical and Electrical Specifications

............................

1-7

1.5.1 Interface Specifications

....................................

1-7

SECTION

11-

INSTALLATION AND INITIAL CHECKOUT

2.1

Introduction.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .

..

2-1

2.2 Uncrating the Disk Drive

.........................................

"

2-1

2.3 Power Connections. . . .. . .. . . .. . . . . . . . .. . . .. . .. . . . . . . . . .. .. . . . . .

..

2-6

2.4 Initial Checkout Procedure. . . . . . . . . . . . . . . . . .. . . .. . . . . . . . . . . . . . . . .

..

2-6

2.5 InterfaceConnections. . . . . . . . . . .. . . . . .. . . . . . . . . . . . . . . . . . . . . . . . ..

..

2-8

2.6 Rack Mounting the Disk Drive

....................................

"

2-11

2.6.1

Slides.

. . . . . . . . . . . . . . . . .. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-11

2.6.2 Installation of Slide Set Part

NO.1

02731

......................

2-11

2.6.3 Installation of Slide Set Part No.

103670

......................

2-12

SECTION

111-

OPERATION

3.1

Introduction

...................................................

"

3-1

3.2 Cartridge Handling

and

Storage

....................................

3-1

3.3 Disk Drive Preparation

............................................

3-2

3.4 Cartridge Loading

and

Unloading

.................................

"

3-2

3.4.1

Loading a Cartridge, Front Load Models

......................

3-2

3.4.2 Unloading aCartridge, Front Load Models. . . . . . . . . . . . . . . . . .

..

3-4

3.4.3 Loading a Cartridge, Top Load Models

.....................

"

3-4

3.4.4 Unloading aCartridge, Top Load Models

.....................

3-5

3.5 Selecting Write Protection. .. . .. . . . . . . . .. . . . . . .. . . . . . . . . . . . . . . . . .

..

3-8

3.6 Starting the Disk Drive

............................................

3-8

3.7 Stopping the Disk Drive

...........................................

3-8

3.8 Designating Unit Number. . . . . . . . .. . . . . .. . . .. . . . . . . . . . . . . . . . . . . . .

..

3-8

3.9

CE

Alignment. . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . .. . . . . . . . . . . . . . . .

..

3-9

3.10 Periodic Maintenance. . . . .. . . . . . . . .. . .. . .. . . . . . . . .. . . . . . . . . . . .. .

..

3-9

3.11

Interlock Protection. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. . . . . . . . . . . . . .

..

3-9

3.12 SafeCondition

...................................................

3-10

3.13 Emergency and Fault Detection

....................................

3-11

3.14 Manual Controls

.................................................

3-11

3.14.1

ON/OFF

.................................................

3-11

3.14.2 RUN/STOP

..............................................

3-11

3.14.3 READy

..................................................

3-12

3.14.4 SAFE

...................................................

3-12

3.14.5

PROT

(Protect)

...........................................

3-12

3.14.6 Unit NumberSelectorSwitch

...............................

3-12

3.14.7 Write Protect

Sw

itehes. . . . . . . . .. . . .. . . . . . . . . . . . . . . .. . . . . .

..

3-12

3.15 03000 Interfacing

..............................................

'"

3-13

3.16 Interface Inputs (Controllerto Disk Drive)

............................

3-13

3.16.1

UnitSeteet Lines

..........................................

3-13

3.16.2 Platter Select. . . . . .. . . . . .. . .. . . .. . . .. . . .. . . . . . . . . . . . . . . .

..

3-13

3.16.3

Head

Select

..............................................

3-13

3.16.4 CylinderAddress Strobe

...................................

3-14

v

TABLE

OF

CONTENTS (Continued)

Page

3.16.5 Cylinder Demand Address

(9

Lines)

..........................

3-15

3.16.6 Restore Initial Cylinder

....................................

3-15

3.16.7 WriteEnable

.............................................

3-15

3.16.8 Erase Enable

.............................................

3-15

3.16.9 Write Data Signal

.........................................

3-16

3.16.10

Read

Enable

..............................................

3-16

3.16.11

Track Offset

..............................................

3-16

3.16.12 Activate Emergency Unload

...

"

...........................

3-17

3.16.13 Start/Stop Disk Drive

......................................

3-18

3.17 InterfaceOutputs (Disk Drive toController). . . . . . . . . . . . . . . . . . . . . . . . .

..

3-18

3.17.1 Ready

...................................................

3-18

3.17.2 Busy Seeking

(4

Lines)

.....................................

3-19

3.17.3 SectorPulse

.............................................

3-19

3.17.4 SectorCount Lines . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-20

3.17.5 Index Pulse

..............................................

3-21

3.17.6

Read

Clock. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .

..

3-21

3.17.7

Read

Data. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-21

3.17.8 Illegal CylinderAddress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-21

3.17.9 File Protected

............................................

3-22

3.17.10 Malfunction Detected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-22

3.17.11

Dual Platter . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-23

3.17.12 Double Track Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-23

3.17.13 Special Interface

Signal.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3-23

SECTION

IV

-THEORY

OF

OPERATION

4.1

Introduction

.....................................................

4-1

4.2 Organization of the Disk Drive

......................................

4-1

4.2.1

Main Chassis Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-1

4.2.2 PositionerAssembly

......................................

4-4

4.2.3 Power Supply Assembly

...................................

4-4

4.2.4 Read/Write, Servo,

and

Logic PCBAs

........................

4-4

4.2.5 Temperature Compensation PCBA

(200

tpi Models)

..

. . . . . . . .

..

4-5

4.3 Functional Subsystems

...........................................

4-5

4.4 Positionerand Positioner Electronics

...............................

4-5

4.4.1

PositionerAssembly

......................................

4-5

4.4.2 PositionerElectronics . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-7

4.5 Read/WriteOperations

............................................

4-10

4.6 Read/Write Electronics. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-11

4.6.1

Head Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . .

..

4-11

4.6.2 Write Electronics

.........................................

4-11

4.6.3

Read

Electronics

..........................................

4-13

4.7 Logic Functions and Control

.......................................

4-16

4.7.1

Logie Arrangement

........................................

4-16

4.7.2 Disk Drive Functional Control

...............................

4-17

4.7.3 Spindle Speed

Control.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-22

4.7.4 Position Control Logic

.....................................

4-25

4.7.5 SectorElectronics

........................................

4-27

4.8 MotorControl. .. . .. . . . . .. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

..

4-30

4.9 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-31

4.10 Temperature Compensation

(200

tpi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-33

vi

TABLE

OF

CONTENTS

(Continued)

Page

SECTION

V - DETAILED ELECTRICAL AND

LOGIC

DESCRIPTION

5.1

Introduction

...........................•........•.................

5-1

5.2 Logic

Term

Mnemonic Identification

..

..

.

..

.

..

. . . . ••

....

..

•

....

..

...

5·1

5.3

Servo

PCBA

.....................................................................

5-1

5.3.1

Voltage Regulators. . . . . . . •. . . . . . .. . . . . . •. . . . . . . . •. . . . . •.

..

5-3

5.3.2 Positioner

Servo

Electronics. .. .. . . .. .. . . ••.. . . . . •. .

..

..

. •

..

5-3

5.3.3

AC

MotorControl Circuits. . •. •. . • •. •. . •. . ••. •. •••••. . . ••.

..

5-9

5.3.4 Cartridge Lock Solenoid Driver

..............................

5-11

5.3.5 Power Clear Control Circuit.

................................

5-11

5.4 Read/Write

PCBA

.........•...........•.........•...••.•.........

5-13

5.4.1

Head

Selection Matrix

and

Select

Amplifier.

. ••. . •. . . . . •. ••.

..

5-13

5.4.2 Writeand

Erase

Drivers

..•.

.. . . . .. . .. . . . ••.. . .. . . .. . .. . •.

..

5-15

5.4.3

Read

Switch

......•..............•...........••...........

5·18

5.4.4

Read

Preamplifier

....••..••••..•.....•••••.•.........••.•.

5·16

5.4.5

Filter.

•. . . . . . . . •. . •. . ••. .•.•. .••. . . .. . . . •. . •••••. . . . . . •

.•

5-18

5.4.8 Variable Gain Amplifier

...................................

5-18

5.4.7

Peak

Detector, Squarer,

and

Pulse Former

.••.............•...

5-18

5.4.8 Data Decoder

CI

rcuitry •. . ••. ••. •••.. .•. . . •••••••••. . . . •••

.•

5·17

5.~.9

Emergency Condition Detection. .. . .•. .•. ••. . .. ••••••. ••. .

..

5-17

5.5 Logic

PCBA

...........•..............•......•.•....•.......••...

5-19

5.5.1

Sheet 2 (Schematic No.

102830)

.............................

5-19

5.5.2 Sheet 3(Schematic No.

102830)

.............................

5-25

5.5.3 Sheet 4(Schematic No.1

02830)

..

. .

..

..

. . . .

..

........

. . .

....

5-29

5.5.4 Sheet 5 (Schematic No.1

02830)

. . •. .. . .. . . .. . .. . . ..

..

. . . . .

..

5·35

5.6 MotorControl PCBA 5-43

5.7 Temperature Compensation

PCBA

. . .. . •. . •. .. . . .. . •. . . . . . . . . . . . . •

..

5-45

SECTION

VI

-MAINTENANCE

AND

TROUBLESHOOTING

6.1

Introduction . . . .. . .. . . .. . .. . .. .. . .. . . .. •. •. .. . .. . . .. ••••. . .. . . .

.•

6-1

6.2 Fuse Replacement

..

,

............................

"

...............

6-1

6.3 Scheduled Maintenance. .. . .. . .. . .•. .. . . . . .. . . •. . .. . .. . .. . .. . . ..

..

6-1

6.3.1

Maintenance Philosophy

...................................

6-1

6.3.2 General Maintenance. . . .. . .. . .. . .•. .. . . . . •. ••••. .. . . . •••

..

6-3

6.3.3 General Precautions. .. . .. . .. . .. . . . . .. . . . . . . . . ••. .. . . .. . .

..

6-3

6.4 Cleaning the Disk Drive

.................................•..........

6-3

6.4.1

Cleaning the Heads

......•.....•..•.....••...••......•••..

8-4

6.4.2 Cleaning the Fixed

Disk..

.

........

. .

..

.

..

.

..

. .

..

•

..

.

....

.

..

6-5

8.4.3 Cleaning theSpindle . . .•. . . . . . . . . •.. . . .. . .. . . .. . .. . .. . ..

..

6-8

6.4.4 Cleaning the Positioner

.•..•......•......•.................

6-8

6.4.5 Cleaning the Base Casting, Dust Cover. and Filters

..•......•..

6-8

6.5 Part Replacement Adjustments

...•.................................

6-9

8.6 Electrical Adjustments. .. .. . . .. . .•.. . . . . . .. . .. . . .. . .. . . . •. . . . .. .

..

6-9

6.6.1

Adjustment Philosophy.. .

..

.

....

.

..

. . . •. .

..

.

..

•. •. . . . •.

...

6-10

6.6.2 10vand5vRegulators

......................................

6-10

6.8.3

AC

Motor

Speed

Control

..

.. . . .. . .•. .. . . . . .. . . . . . . . . . . . . .

..

6-12

6.7 Positioner

Servo

Calibration

....................•..................

6·14

6.7.1

Positioner Preparation forStaticTests

.....•..•..............

6·14

S.8

Static PositionerAdjustments

...........•..............•••.........

6-16

6.8.1

X + 0

Gal

n

and

Balance. . .. . . .. . .. . .. . . . . . . . . . . . . . . . . . . . .

..

6·16

6.8.2 X +

90

Gain

and

Balance. . . •. . .. . .. . . . . . . . . . . . . . . . . . . . . . .

..

6-18

vii

!53DD

TABLE OF CONTENTS (Continued)

Page

6.8.3 X + 0and X +

90

Signal Polarity

and

Quadrature Check

........

6-1S

6.8.4 Heads Retracted Signal Check . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-21

6.8.5 Index Balance

............................................

6-22

6.S.6 Velocity Transducer Phasing. .. . . . . . . . . . . . . . .. . . . . . . . . . . . .

..

6-24

6.8.7 PositionerVoice Coil Polarity Check. . . . .. . . . . . . . . . . . . . . . . .

..

6-25

6.8.S Power-Down Procedure. . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .

..

6-25

6.9 Dynamic Positioner AdJustments. . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .

..

6-26

6.9.1 Positioner Preparation, Dynamic

Tests.

. . . . . . . . . . . . . . . . . . . .

..

6-26

6.9.2 Dynamic Adjustments

..

;

..................................

6-26

6.9.3 Dynamic Reticle-to-Scale Phase Adjustments. . . . . . . . . . . . . . .

..

6-30

6.9.4 Current Adjustment

..

. .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

..

6-31

6.9.5 Seek-Time Adjustment

.....................................

6-32

6.9.6 Overshoot Test Procedure. . .. . . . . . . . . . . . . . .. . .

..

. . . . . . . . .

..

6-33

6.9.7 Overshoot Adjustment Procedure

...........................

6-35

6.9.8 Index to Quadrature Clock Relationship

......................

6-35

6.9.9 Overshoot and Settling Response Procedure. . . . . . . . . . . . . . . .

..

6-39

6.10 Performance Checks. : . . .. . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . .

..

6-41

6.10.1

Servo and PositionerTest . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . . .

..

6-41

6.10.2 Spindle

Speed

Accuracy Test

..

.. . . . . . . . . . . . . . .. . . . . . . . . . .

..

6-41

6.11

Sector Phase-Lock-Loop Adjustment. . . .. . . . . . . . . . . . . . .. . . . . . . . . . .

..

6-42

6.11.1 Test Configuration

..

. .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

..

6-43

6.11.2 Test Procedure

...........................................

6-43

6.11.3 Adjustment Procedure. .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

..

6-43

6.12

Read

DecodeCircuit Adjustments

..................................

6-44

6.12.1

Read

Pulse Narrow (RPN) Pulsewidth Adjustment

.............

6-44

6.12.2 'Ones' Window Setting

.....................................

6-45

6.12.3 Data

and

Clock Pulsewidth

.................................

6-46

6.13 Temperature Compensation

(200

tpi Only)

...........................

6-47

6.13.1 Temperature Compensation Tests

and

Adjustments. . . .. . . . . .

..

6-47

6.13.2 Scaling ResistorVerification. . . . . . . . . . . . . . . . . . . . . . . .

..

. . . .

..

6-48

6.13.3 Environment Temperature Adjustment . . . . . . . . . . . . . . . . . . . . .

..

6-48

6.14

CE

Alignment Procedure

..........................................

6-51

6.14.1 Front Loading

CE

Disk Cartridge

..

. . . . . . . . . . . . . . . . . . . . . . . .

..

6-51

6.14.2 Top Loading

CE

Disk Cartridge

..............................

6-52

6.14.3

CE

Cartridge Stabilization

..................................

6-53

6.14.4 Test Configuration -All Models

............................

6-53

6.14.5 Radial Alignment -Front Load

.............................

6-54

6.14.6 Circumferential Alignment -Front Load

.....................

6-60

6.14.7 Radial Alignment -Top Load

..............................

6-63

6.14.8 Circumferential Alignment -Top Load

......................

6-67

6.15 Cartridge InterlockSystem -Front Load Models

.....................

6-69

6.15.1 Checking the Interlock System -Front Load Models

...........

6-69

6.15.2 Adjusting InterlockSystem

.................................

6-69

6.16 Cartridge InterlockSystem -Top Load Models

.......

,

...............

6-71

6.16.1

Checking the InterlockSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-72

6.16.2 Adjusting the InterlockSystem

..............................

6-72

6.17

Bezel

and PowerSwitch

...........................................

6-75

6.17.1 Removal of

Bezel

.........................................

6-75

6.17.2 Installation of

Bezel

..

.. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

..

6-75

6.17.3 Removal of Power Switch Bracket

...........................

6-75

viii

TABLE OF CONTENTS (Continued)

Page

6.18 Magnetic Transducer

Gap

.........................................

6-76

6.18.1

Upper Transducer Test

and

Adjustment -Top Load Models

.....

6-76

6.18.2 LowerTransducer Alignment -Top Load Models

.............

6-77

6.18.3 LowerTransducer Alignment -Front Load Models

............

6-77

6.19 Disk Drive Pulley System

...

.. . . . . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . .

..

6-78

6.19.1

Belt Removal. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . .

..

6-78

6.19.2 Belt Replacement .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .

..

6-78

6.20 Static Discharge Contact

..........................................

6-80

6.21

Care and Handling of Heads

.......................................

6-81

6.21.1

Load Pin Seating. . . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

..

6-82

6.22

Head

Removal and Installation

.....................................

6-82

6.22.1

Head

Removal Procedure

...................................

6-82

6.22.2 Head Installation Procedure

...

.. . . . . . . . . . . . . .. . . . . . . . . . . .

..

6-85

6.23 Lamp/Lens Assembly Removal and Installation

.......................

6-87

6.23.1

Lamp/Lens Assembly Removal

.............................

6-87

6.23.2 Lamp/Lens Assembly Installation

...........................

6-87

6.24 Reticle Removal and Installation

........................

: . . . . . . . . .

..

6-87

6.24.1

Reticle Removal

..........................................

6-87

6.24.2 Reticle Installation . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

..

6..a8

6.25 Scale Assembly Removal

and

Installation

............................

6-88

6.25.1

Scale Assembly Removal. .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .

..

6-88

6.25.2 Scale Assembly Installation

................................

6-89

6.26 Air

Filter.

. . . .. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .. . . .. . . . . . . . . .

..

6-89

6.26.1

Pre-Filter Cleaning . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

..

6-90

6.26.2 Removal of Absolute Filter

.................................

6-90

6.26.3 Replacement

of

Absolute Filter

.............................

6-90

6.27 Power Supply. . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

..

6-90

6.27.1 Power Supply Removal

....................................

6-91

6.27.2 Power Supply Installation

..................................

6-91

6.28 Drive Motor. . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . .

..

6-92

6.28.1

DrIve MotorRemoval

......................................

6-92

6.28.2 Drive MotorInstallation

....................................

6-92

6.29 MaintenanceTools

...............................................

6-94

SECTION

VII

-

PARTS

LISTS

AND SCHEMATICIASSEMBLY DRAWINGS

7.1

Introduction

.....................................................

7-1

7.2 Illustrated Parts Breakdown (IPB)

...................................

7-1

7.3 Recommended Spare Parts

........................................

7-1

7.4 Part NumberCross Reference List

...

,

..............................

7-1

7.5 Integrated Circuit

Pin

Summary

....................................

7-1

7.6

PCBA

Interconnections

...........................................

7-1

APPENDIX A - 03000 MNEMONICS

APPENDIX B - TROUBLESHOOTING

ix

Figure

1-1

1-2

1-3

1-4

1-5

1-6

1-7

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

3-1

3-2

3-3

3-4

3-5

LIST OF ILLUSTRATIONS

Page

Model Identification

.,

...............................................

1-1

03000 Disk Drive, Top Load Model

....................................

, 1-3

03000 Disk Drive, Front Load

Model.

. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

..

1-3

Functional Block Diagram

............................................

1-4

Mechanical Sectoring

.........

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-5

Platter, Cylinder, Track Relationship

...................................

1-6

InterfaceConfiguration

..............

,

................................

1-9

Cartridge Receiver and Front Door Shipping Restraints

...................

2-2

Rack Mounting the 03000 Disk Drive

...................................

2-3

Component Identification, Logicand Servo PCBAs Extended

..............

2-4

Component Identification

............................................

2-4

Counterweight in Shipping

Position.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-5

Counterweight in Operation Position . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

..

2-5

InterfaceConnector Board Installation

..................................

2-10

Mounting Bracket

to

EIA Cabinet; Hardware Orientation for

Use

with

PIN

103670

.................................................

2-13

Inside Measurement Between Slide Brackets

............................

2-14

Cartridge Loading/Unloading, Front Load Models

........................

3-3

Cartridge Loading/Unloading, Front Load Models

........................

3-3

Cartridge Inserted, Front Load Models

.....

,

............................

3-3

Cartridge Loading, Top Load Models (Lock Arm Away from Disk Area)

......

3-6

Cartridge Loading, Top Load Models (Release/Lock Down)

................

3-6

3-6 Cartridge Loading, Top Load Models (Release/Lock Up)

..................

3-6

3-7 Cartridge Loading, Top Load Models (Cartridge Positioned Over

Adapter Bowl . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

..

3-6

3-8 Cartridge Loading, Top Load Models (Cartridge Loaded,

Release/Lock Down)

.................................................

3-7

3-9 Cartridge Loading, Top Load Models (Lock Arm Over Cartridge Cover)

......

3-7

3-10 Cartridge Unloading, Top Load Models

.................................

3-7

3-11

Cartridge Unloading, Top Load Models

.................................

3-7

4-1

03000 Disk Drive Organization

.........................................

4-2

4-2 Positionerand Positioner Electronics, Functional Block Diagram

...........

4-35

4-3 Double Frequency Recording Flux and Pulse Relationship

.................

4-11

4-4 Read/Write Electronics, Functional Block Diagram

..

,

....................

4-37

4-5 Peak Detector and SquarerWaveform

........

, . . . . . . . . . . . . . . . . . . . . . . . .

..

4-14

4-6 Double Frequency GeneratorTimi

ng

Relationship , . . . . . . . . . . . . . . . . . . . . .

..

4-14

4-7 Data DecoderTiming Relationship

.....................................

4-15

4-8 Digital Sequential Machine Block Diagram

..............................

4-18

x

LIST

OF

ILLUSTRATIONS (Continued)

Figure

Page

4-9

Start/Stop Control, Functional Block Diagram

..........................

,

4-39

4-10

SpindleSpeed Control, Functional Block Diagram

.......................

4-41

4-11

Position Control Logic, Functional Block Diagram

.......................

4-43

4-12 Sector Electronics, Functional Block Diagram

...........................

4-45

4-13

Power Supply, Functional Block Diagram. . .. . . . . . . . . . . . . . . .. . . . . . . . . .

..

4-32

4-14

Transformer Primary Connections

.....................................

4-33

4-15

Temperature Compensation, Functional Block Diagram

...................

4-47

5-1

Servo

PCBA

Test Point

and

Connector Placement

........................

5-2

5-2

Position Transducer Output Signals. .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .

..

5-6

5-3

Position Transducer Signal AmplifierOutputs . . . . . . . . . . . . . . . . . . . . . . . . .

..

5-6

5-4

Fault Detection Waveforms

...........................................

5-12

5-5

Read/Write C PCBA, Test Point

and

Connector Placement

...............

5-14

5-6

Logic PCBA, Test Point

and

Connector Placement

.......................

5-20

5-7

MotorControl PCBA, Test Point

and

Connector Placement. . . . . . . . . . . . . .

..

5-43

5-8

Temperature Compensation PCBA, Test Point and Connector Placement. .

..

5-45

6-1

Slider Defects and

Head

Contamination which Require Cleaning Action

.....

6-6

6-2

Slider Defects

and

Head

Contamination which Require

Head

Replacement

...

6-7

6-3

AC

MotorSpeed Control Signal Pulsewidth

.............................

6-13

6-4

Position Transducer Signal Amplifier Outputs . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-17

6-5

X + 0 Analog Signal Added to X +

90

Digital

Signal.

. . . . . . . . . . . . . . . . . . .

..

6-20

6-6 X + 0Waveform, One-Track Repetitive

Seek

............................

6-28

6-7

Balanced Waveform, One-Track Repetitive Seek

.........................

6-28

6-8 Analog Waveform Limits, One-Track Repetitive

Seek

.....................

6-28

6-9 X + 0Waveform Crossover

..

. .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .

..

6-29

6-10

Current Waveform After Adjustment of

R111

.............................

6-33

6-11

Velocity Feedback Waveform,

TP16

. .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . .

..

6-33

6-12

X + 0Waveform

000-001

Repetitive Track

Seek

..........................

6-34

6-13

SPRCG,

SPTIG,

SPQCG

Signals, Repetitive Restore Mode

................

6-36

6-14

Correct Relationship Between

SPQCG

and

SPTIG

Signals, Extended

........

6-37

6-15

Index Signal,

TP3,

Repetitive Restore Mode

.............................

6-38

6-16 X + 0 Overshoot and Settling Response Waveforms

......................

6-40

6-17

X +

90

Waveform for Long Track Seeks

.................................

6-41

6-18

Quadrature Relationship Between Sector Phase-Lock-Loop Square Waves

...

6-42

6-19

Read

Pulse Narrow1'0nes'Window . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. .

..

6-44

6-20

Read

Clock/Read Data Pulsewidth

.....................................

6-46

6-21

CylinderAddress Temperature/Voltage Conversion at

TP4

................

6-49

xi

83CD

LIST

OF

ILLUSTRATIONS (Continued)

F~u~

P~e

6-22

TP3

Temperature/Voltage Conversion

..................................

6-49

6-23

TP2

Temperature/Voltage Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-50

6-24

Approximately Aligned Front Load Disk Drive

............................

6-54

6-25A Head Alignment (IBM

CE

Cartridge), Track100, Front Load DiskDrives

.••...

6-56

6-25B Head Alignment

(3M

CE

Cartridge), Track100, Front Load Disk Drives

•.....

6-57

6-26 Radial Alignment, Heads Aligned. .. . . . . •. . . . . •. . . . . . . . . . . ••••••. . . ••

..

6-58

6-27

Radial Alignment. . ••. •. . . . . . . . .. . . ••. •. . . . . •. .. . .. . . . . . . •. •. •••. . .

..

6-59

6-28 Circumferential Alignment, Front Load Drives . . . . . . . . . . . . .. •. . . . . . . . . •

..

6-61

6-29

Compromise Circumferential Alignment, Front Load Drives

...............

6-61

6-30

Radial Alignment,

Head

Aligned. . . .. . . . . . . . . . . . .. . . . . . . . . . . . . •. . . .. .

..

6-63

6-31

Radial Alignment

....................................................

6-65

6-32

Solenoid Location and Clearance

.............................•••.•••..

6-70

6-33

Retracted Solenoid Plunger and Lock-Arm Clearance . . . . . . . . . . . . . . . . . . •

..

6-73

6-34

AdapterCasting and Lock-Arm Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . •.

..

6-73

6-35

Upper Magnetic TransducerGap

.................................••••..

6-74

6-36

GO/NO

GO

Adjustment Tool,

End

View

................................

6-74

6-37

Switch Bracket and Air Filter Retaining Screw Locations

......•...........

6-75

6-38

UpperTransducer Alignment, Top Load

Only.

. . . . . . . . . . . . . . . . . . . . . . . . .

..

6-77

6-39 Lower Transducer Alignment, Front and Top Load

........................

6-78

6-40 Belt Treading Pattern

......................................•.•.......

6-79

6-41

Examples

of

Proper Care and Handling of

Heads.

. . . •. . . . . . . •••. ••••. . .

..

6-81

6-42 Examples

of

ImproperCare and Handling

of

Heads. . . . . . . . . . . ••. . . . . . . .

..

6-82

6-43 Load Pin Seating . .. . . . . . . . . . . . . . .. . . •. .. . . •. . . . . •. . . . •••. ••.. . . . . .

..

6-83

6-44

Heads Installed

on

Positioner Carriage

(200

tpi)

..........................

6-84

6-45

Head-to-Carrlage Adjustment

.........................................

6-86

6-46 Drive MotorCable Routing

............................................

6-93

6-47

Drive Motor Replacement

.............................................

6-93

7-1

03000 Disk Drive Photo Parts Index, FrontView.

..

..

. . . . . . . .

..

•

..

..

•

..

...

7-2

7-2 03000 Disk Drive, Photo Parts Index

...........•.•..........••..•••••...

7-4

7-3 03000 Disk Drive Photo Parts Index (Top Load Models)

•.......•.••...•••..

7-6

7-4 03000 DiskDrive Photo Parts Index, PCBAs in Extended Position

••.•......

7-8

7-5

03000 Disk Drive Photo Parts Index, Bottom

View.

. . . . . . . . . . . . . . . . . . . . .

..

7-10

7-6

03000 Disk Drive Photo Parts Index, Power Supply Assembly

..............

7-12

7-7

03000 Disk Drive Photo Parts Index

(200

tpi Models Only)

.................

7-14

7-8

PCBA Interconnections, Block Diagram

................................

7-25

A-1

MnemonicConstruction

.................................•.•.••..••...

A-1

xii

LIST

OF

TABLES

Table

Page

1·1

Mechanical and Electrical Specifications

........•..•.........•...•.....

1-8

2·1

Power Cord ColorCode

................•...........•.....•.•.•.....•.

2-7

2·2 Interface Input/Output Lines

............................•.............

2-9

3-1

Platter and

Head

Selection.. . . . . . .

..

....

..

..

..

. . . . . . . . . . .

..........

...

3-14

3·2

TRACK

OFFSET Operation

............•..........•...................

3-17

5-1

Clock Countdown

.................

.. .. . . . . . .. . . . . .. . . . . . . . . . . . . . . .

..

5-21

6-1

Fuse Requirements. •. •. . . . .• .. . . .. . . •. .. . . •. . . . . •. . . . . •. •. . . . . . . •.

..

6-1

6-2 Preventive MaintenanceSchedule

......................................

6-2

6-3

Part

Replacement AdJustments. . . . . . . . .. . . . . . .. . . . . . . . . . . . . . . .. . . . . .

..

6-9

6-4 Repetitive Track

Seek

Settings forOvershoot and Settling Response Tests.

..

6-39

6-5

RPN

Pulsewldth Values

............................

'"

................

6-45

6-6 VoltageTolerance at

TP4

.....

'.

. . . . . . . .. . . . . . .. . . . •. . . . . . . . .. . . . . . . .

..

6-67

6-7

Cylinder Address Voltage Limitsat

TP4

. . •. . . . . .•. . . •. . . . . . . . . . •. . . . •.

..

6-50

6-8

UpperTransducer Calibration Data. .. . . . . . . . .•. . . •. •. . . . .•. •. •. . . . . •.

..

6-76

6-9 Pulley and Belt Identification. . . . . . . . .. . . . . .. . . . . .. •.. . . .. . •••. . . •. . .

..

6-79

7·1

03000

Disk Drive Photo Parts Index

..............

"

........

"

..........

7-3

7-2

03000 Disk Drive Photo Parts Index

........................•...........

7-5

7·3 03000 Disk Drive Photo Parts Index (Top

Load

Models). . . . . .. . . .. . . . . . . .

..

7-7

7-4

03000 Disk Drive Photo Parts Index

....................................

7-9

7-5

03000 Disk Drive Photo Parts Index

..............•.........•.........•.

7-11

7-6

03000 Disk Drive Photo Parts Index

....................................

7-13

7-7

03000 Disk Drive Photo Parts Index

........................•...........

7-15

7-8

Recommended Spare Parts List

.........................•.............

7-16

7-9

Part

NumberCross Reference. .. . . . . . . . . . . . . . . .. . . . .. . . . . . . . . .•.. . . .

..

7-17

7-10

IC

Power

and

Ground

Pin

Summary

....................................

7-20

7-11

Function Control Summary

..•.•................................•.....

7-20

7-12

PCBA

Interconnections

....................•.........................

7-21

A-1

Functional Group Classification

.....................................•.

A-1

A-2 Signal Type Classification . •. . . . .. . . . . . . . . . .. . .. . . . . . . . .. . . . . . . . . . . .

..

A-2

A-3 03000 Mnemonics

.................................................•.

A-3

xiii

SEcnON

I

GENERAL DESCRIPTION AND SPECIFICAnONS

1.1 INTRODUCnON

This section provides a physical description, functional description, and specifications for

the 03000 Series Disk Drive, Models 03300 and 03400, manufactured by the

PERTEC

Division

of

PERTEC

ComputerCorporation, Chatsworth, california.

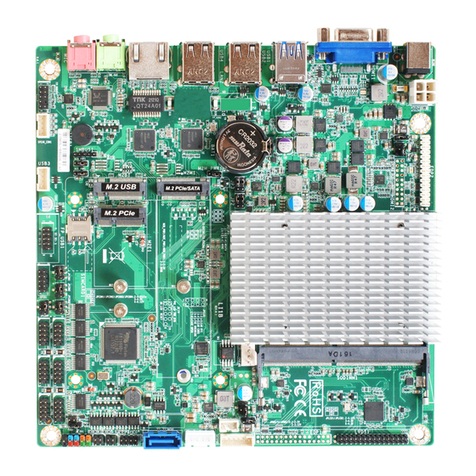

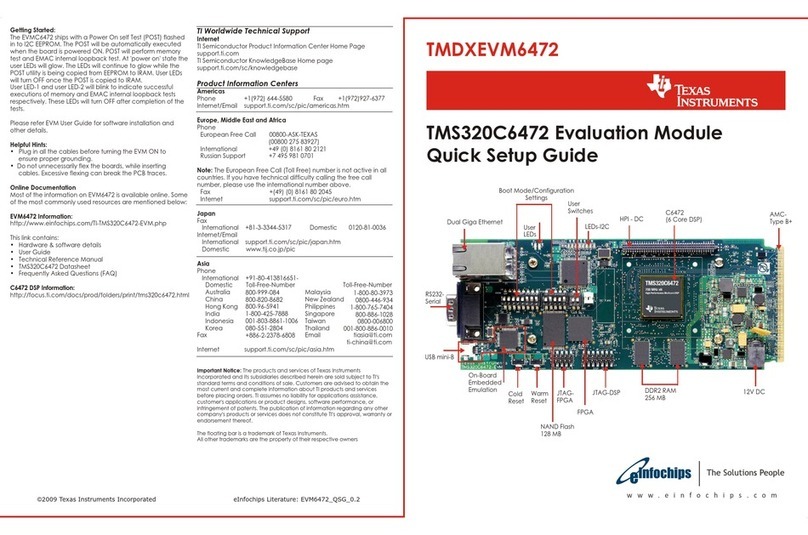

1.1.1 MODEL IDENTIFICATION

To

simplify

identification

of

03000 Series Disk Drives, Figure

1-1

Illustrates the breakdown

of

code combinations employed by PERTEC.

03XXX-XXXX-XXX

'L-

Optional Designator

WX

=Write Protect Switches

XU

=UnitNumber SelectorSwitch

SC

= Special Configuration-

OptionallnputiOutput

Interface

N =Normal

C =Compatible--

S =Special-

Number of Sectors

SectorConfiguration

I = Electronic on Index Only Cartridge

E = Electronic on Multi-Notched Cartridge

M = Mechanical

Speed Classification (Spindlerpm)

1 =1500

2 =2400

RemovableCartridgeIFixed DiskConfiguration

1 =5440-type Cartridge Only (100 tpi)

2 = 5440-type Plus Fixed Disk (100

or

200

tpi)

3 =2315-typeCartridge Only (100tpi)

4 =2315-type Plus f'lxed Disk (100

or

200

tpi)

Density

3 =

2200

bpi, 100 tpi

4 =

2200

bpi, 200 tpi

Basic Designator

•As specifically ordered; not described in

this

manual.

--Electricallycompatible with controllers designed

to

interlace

to

another manufacturer's

diskdrive.

Figure1-1. Model Identification

1-1

Referring to Figure 1-1, the following illustrates the

ease

of

Identification, using Model

D3322-1064-NWU

as

an

example.

(1)

03 is the basic prefix used on all 03000 Series.

(2)

3 in thethird position indicates a1

00

tpi device.

(3)

2 in the fourth position indicates a5440-type cartridge plus fixed disk.

(4)

2 in the

fifth

position indicates aspindle speed of

2400

rpm.

(5)

I in the sixth position indicates that the 5440-type cartridge

to

be utilizea has a

normal index notch only.

(6)

064

in theseventh, eighth,

and

ninth positions indicate a64-sectordevice.

(7) N in the tenth position indicates a Normal (standard) interface configuration

option.

(8) W in the eleventh position indicates the unit is provided with Write Protect

switches.

(9) U in the twelfth position indicates the unit is provided with Unit Number Selector

switch.

1.2

PURPOSE

OF

EQUIPMENT

The disk drive has the capability

of

recording digital data on IBM

2315-

or 5440-type

cartridges utilizing the double-frequency method of recording. Spindle speeds up to

2400

rpm and data storage

of

up

to101.5 megabits are provided by the 03000 Series Disk Drive.

Data recorded on the removable media

can

be

recovered when played back on any 03000

Series having the same cartridge type, density, format,

and

speed.

The 03000 is a rotating magnetic memory capable of storing and retrieving data in digital

form.

The

storage media is

an

aluminum disk coated

on

both surfaces with a layer

of

ferro-

magnetic material suspended in a binder. Data

are

stored serially in concentric tracks

on

both surfaces

of

the disk.

The basic disk drive is available

as

a single-disk or dual-disk device. All models are

capable

of

accepting removable media with the removable disk enclosed in a cartridge

assembly. Depending

on

the model, the disk drive will accept either the top loading

5440-type

or

the front loading 2315-type cartridge.

Single-disk models

have

provisions for the removable cartridge only; dual-disk models

have

provisions for the removable cartridge

and

a fixed disk enclosed within the drive

housing.

The disk drive is intended for use in conjunction with a formatter

or

controller to provide

rapid access mass memory for small and medium size computers.

An integral power supply is included in the disk drive

and

operates directly from Single

phase power.

1.3

PHYSICAL

DESCRIPTION

OF

EQUIPMENT

The

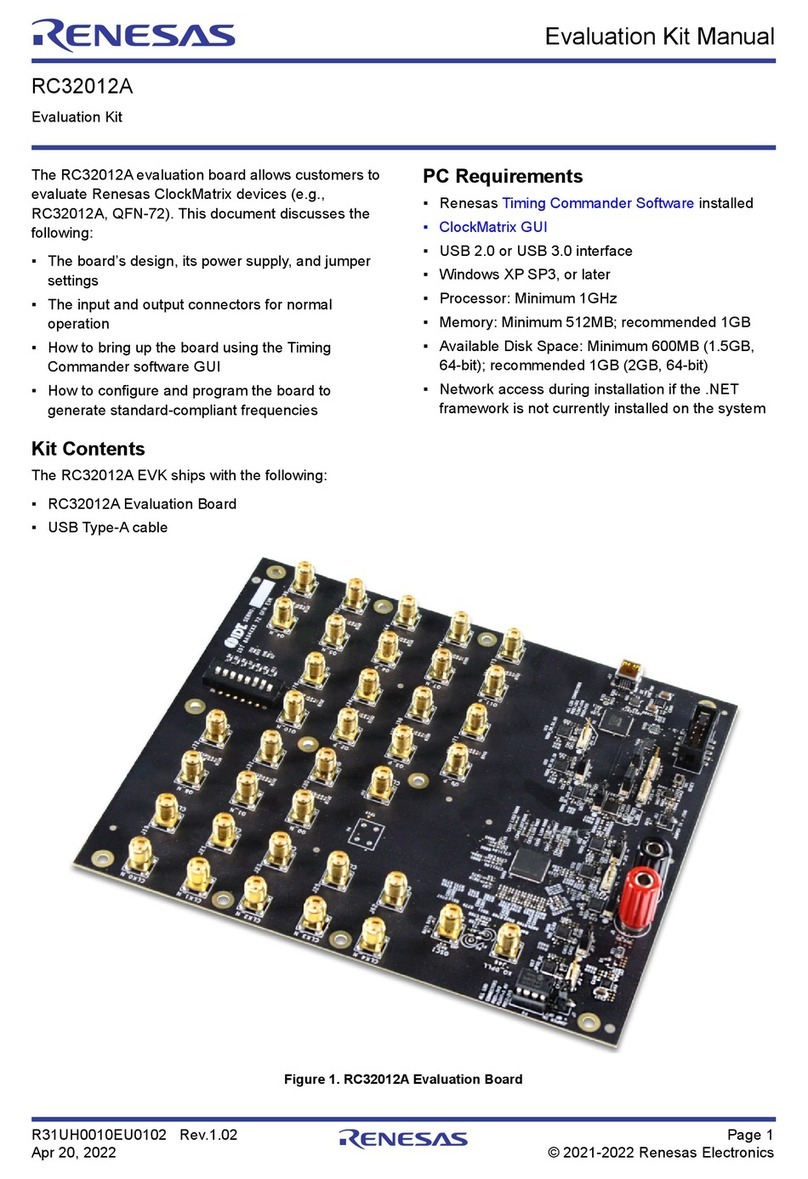

top loading configuration of the 03000 Disk Drive utilizes a 5440-type cartridge and is

shown in Figure 1-2; the front loading configuration utilizes a 2315-type cartridge and is

shown in Figure1-3.

1-2

Figure1-2. 03000 Disk Drive,

Top Load Model Figure1-3. 03000 Disk Drive,

Front Load Model

All

electrical and mechanical components necessary

to

operate

the

disk

drive are mounted

Internally

within

the housing

of

the

drive. The housing

is

designed

to

be mounted in a

standard 1g..inch EIA rack, orutilized

as

a table top unit.

All

models are equipped

with

the necessary electronics

to

provide recording and retrieval

of

stored data.

Access

to

the interior

of

the

disk

drive

Is

gained by removing the

dust

cover. This cover is

mounted

to

the base assembly and protects the interior

of

the

drive

from

dust and other

environmental contam;nants.

The operational controls, which include indicators that are illuminated when the relevant

functions are being performed, aremounted on the front control panel. These controls are

acces~ible

t('l the operator at all times. Power is supplied through a strain·relieved cord

having a standard 3--prong plug. Interface signals are routed through the interface cables

to

input/output

connectors located

within

the

disk

drive housing.

The major electronic assemblies are located near the rear

of

the

drive. These assemblies

are mounted to

allow

ready access

without

the use

of

extender cards or other special

tools.

1.4 FUNCTIONAL DESCRIPTION

Data storage is accomplished by utilizing the non-contact method

of

magnetic recording.

The disk recording media is rotated at a constant speed and the recording heads, capable

of

either reading orwriting, are flown over the surface

of

the

disk

on a gas-film bearing and

positioned

to

the appropriate track by the use of a voice-coil type

of

linear

motor

positioner. This type

of

disk

drive, which utilizes a single head per surface, is referred to

as a moving-head

disk

drive.

Addressing

of

the stored data isaccomplished by specifying thedesired head position and

the applicable segment

of

the

disk

surface. The read/write electroniCS are capable

of

non·simultaneous reading

or

writing

of

data on a single surface at a given time.

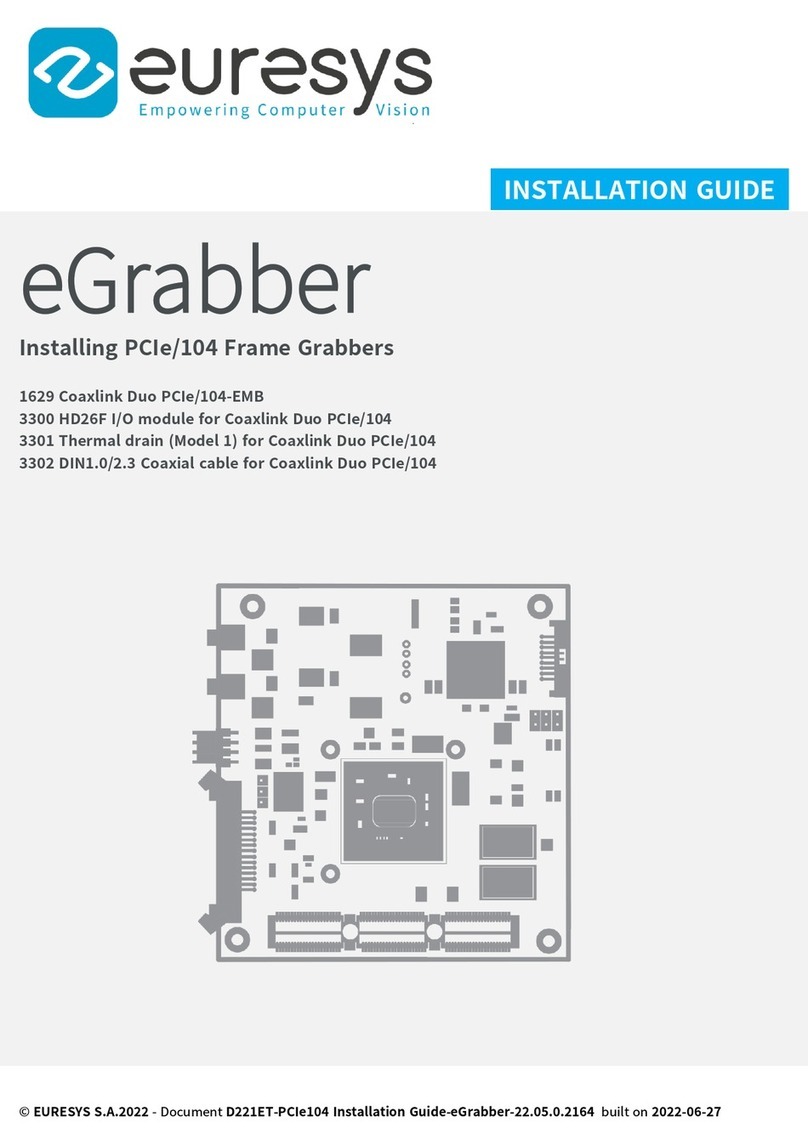

Figure1-4 is a functional block diagram

of

the

disk

drive, which

consists

of

the

disk

drive

control logic, start and stop control plus auxiliary controls, and the necessary select and

enable gating.

1-3

SECTOR

INDEX

CClINT

SECIOR

HE

CIRONICS

I·

0 CONIRlJL

SIGNALS

DISI::

DRIVE

FUNCIION

CONIlCL

tLECTIONICS

L-----------J.;ONTROL

SIGN

...

LS

REMOVABLE

DISK--_

CAIIRIOGE

HEAD

Sf

LEO

WRIlE

ELEORONKS

IIfAD

ELECTRONICS

CLOCK

0

...

1

...

POSITIONER

SPINDLE

SPUD

CONTROL ElECTRONICS

MOTOR

TRANSDUCER

______

../

POWEl

SUPPL

Y

-------------------------~--POWf.

LINE

Figure 1-4. Functional Block Diagram

DC

powER

TO

ElECTRONICS

POSITIONER

SUVO

ElECTRONIC>

1648

The positioner servo electronics comprise a major functional block. As the disk rotates

at

a fixed speed, and the recording heads are flown over the disk surface, the positioner is

controlled

In

both the velocity and position modes. The positioner moves

to

the correct

address undercontrol

of

the pOSitioner servo control electronics. Data are then written on

the desired surface by selecting thecorresponding

head

through the

head

select network.

The

read

/write electronics are subdivided into three functional blocks consisting of the

head

select network, the write electronics, and the read channel. Write data causes write

current to

be

switched according to the pulse train on the

WRITE

DATA SIGNAL line.

The

storage

surfac~

will then

be

magnetized accordingly.

During retrieval

of

the stored data, the corresponding head

is

again selected by the

head

select network and the signal obtained from the read/write head Is processed

by

the

read

channel Into separate

READ

DATA and

READ

CLOCK Signals for transmission via the

interface. The particularsegment

of

the diskwhich Is pasSing under the read/write

head

is

specified by the sectorpulseand sector count lines from the sectorelectronics.

Control of the rotational speed

of

the disk is accomplished by the speed control

electronics group which establishes a known, fixed speed

for

the disk rotation within ±1

percent

speed

tolerance. The sector electronics block provides pulses at the Interface

which electrically subdivides the disk Into a number

of

sectors for the purpose

of

addressing datastored on the disk. Figure1·5 Illustratesthe subdiviSion

of

a platter Into 8

sectors by means

of

mechanical sectoring.

The air system consists

of

an

absolute filter preceded by a pre.fllter, and a blower driven

by the same motor which provides drive

to

the disk spindle. This air system provides a

well-filtered flow

of

clean air in thedisk area to remove contaminants.

Power to the various electronic circuits Is provided by

an

integral power supply. This

power provides dc voltages at suitable levels derived from the linevoltage.

All major components are mounted to the base assembly. An aluminum alloy casting

Is

the basic component of the base assembly. Mounted onto the casting is the drive

mechanism'which consists

of

a precision spindle,

an

ac Induction drive motor, a squirrel

cage blower, and

an

idler system. Power

to

rotate the blower and spindle

is

transmitted

from thedrive motorby means

of

a flat belt. The Idler system provides constant tension

of

the beltand compensates forstretch

of

the belt.

SECTOR

SLOT

INDEX

SLOT

TOP

VIEW

Figure1-5. Mechanical Sectoring

1-~

Mounted to the spindle assembly isa ring with equally spaced notches and one additional

notch spaced midway between two of the other notches; this is referred to as the Phase

Lock Ring and is used for sectoring

and

speed control.

In

dual disk models, a fixed disk is mounted to the spindle assembly; it is referred to

as

the lower disk but is not removable

in

the same manner

as

the cartridge. The second

disk is contained within the removable cartridge and is driven by a magnetic clutch which

is located

on

top

of

the spindle assembly. A precision ground cone

on

the

end

of

the

spindle suitably locates the hub

of

the disk which is mounted in the cartridge. Rotary

motion is imparted to both disks simultaneously.

The

blower is rotated while the drive motor is running and the disk is spinning. Air flow

from the blower travels through the disk area and purges the air of any contaminants in

this

area.

Air is drawn

in

at the lower front part of the front

bezel

and passes through a high

efficiency absolute filter located in the lower front portion of the baseassembly.

Air is ducted to the squirrel cage blower and thence to the area below the fixed disk.

Suitable vanes

on

the spindle provide additional pumping action to cause air

to

flow into

the

area

of the upper disk. Air is exhausted at the rear

of

the disk drive.

As

a function of

exhausting the air, the electronics package Is provided with Suitable cooling.

Additional cooling is provided through convection cooling of the heatsink assemblies

mounted at the rear of the base assembly. Power transistors mounted on these heatsink

assemblies are used in the power supply regulators

and

the positionerpower amplifiers.

The base assembly provides mounting attachment pOints for the rack mounting slides,

switch brackets, front bezel,

and

the supporting structure for the printed circuit boards

and dust cover.

The

pOSitioner, in conjunction with the positionerservo and control electroniCS, is used to

position the read/write heads

to

one of a possible

203

or

406

cylinders. Figure 1-6 defines

the relationship between disk, cylinder, and track

as

used throughout this document.

The positioner assembly consists

of

a large permanent magnet, a carriage which utilizes

ball bearings, a magnetic velocity transducer, and a photo-electric position transducer.

Attached tothe carriage

are

the read/write heads,

and

the pOSitioner coil (voice coli).

Figure1-6. Disk, Cylinder, Track Relationship

1-6

This manual suits for next models

1

Table of contents

Popular Computer Hardware manuals by other brands

Euresys

Euresys eGrabber installation guide

StarTech.com

StarTech.com PCI1S950DV instruction manual

EK

EK Quantum PC-O11D XL D5 PWM D-RGB user guide

Lexicon

Lexicon MPX 100 Update Installation Instructions

Freescale Semiconductor

Freescale Semiconductor TWR-MCF51QM quick start guide

Kontron

Kontron COMe-mTT10 user guide