FIT-1003-M Operation & Maintenance Manual

Paragon Controls Incorporated 2 Revision Level 002

2. CALIBRATION

It is recommended that the DPT ZERO Calibration be performed upon installation. Span Calibration is

not affected by the Zero Calibration. The Span of the unit has been factory calibrated and should only be

adjusted using high accuracy test equipment. Refer to sections 1.1.1 and 1.1.2.

Zero Calibration Equipment Required:

- DMM (Digital Multi Meter)

Span Calibration Equipment Required:

- Low pressure air source (Paragon PS-100 or equivalent)

- Manometer for measuring low pressure

- DMM (Digital Multi Meter)

2.1. DPT ZERO CALIBRATION

The following zero calibration procedure can be performed without the need to perform a span

calibration.

Step 1. Remove the cover by removing the 4 mounts screws.

Step 2. Apply power to the transducer and verify Power Status LED is illuminated.

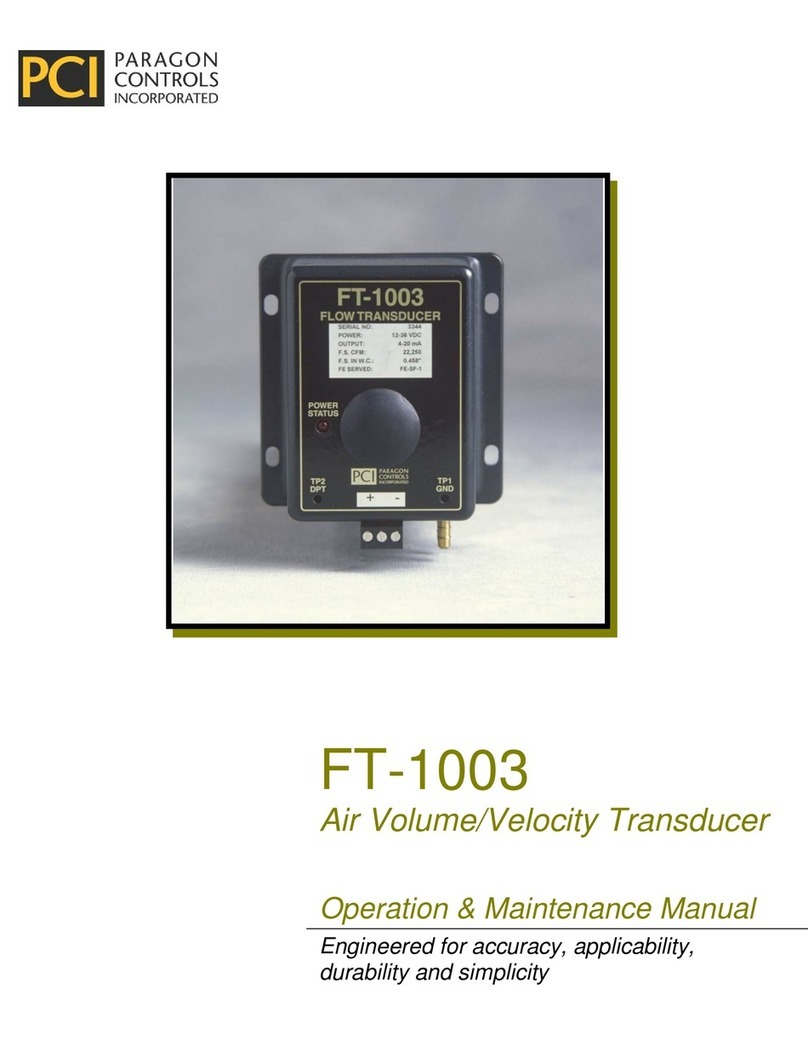

Step 3. Using a DMM set to voltage mode, monitor between TP1 (GND) and TP2 (DPT).

Step 4. With zero pressure applied, adjust DPT ZERO potentiometer for a reading of

0.0±.001vdc.

2.2. OUTPUT SPAN CALIBRATION

Note: It is recommended that a zero calibration be completed before performing a span calibration.

2.2.1. 0-5VDC Output Procedure

Step 1. Using a DMM set to voltage mode, monitor between (SIG) and (-) terminal.

Step 2. Apply full scale pressure (Value shown on the transducer label) to the Total (High)

Pressure port and adjust the SPAN potentiometer for an output reading of

5±.01vdc.

Step 3. Reinstall the cover and 4 mounting screws.

2.2.2. 0-10vdc Output Procedure

Step 1. Using a DMM set to voltage mode, monitor between (SIG) and (-) terminal.

Step 2. Apply full scale pressure (Value shown on the transducer label) to the High

Pressure port and adjust the SPAN potentiometer for an output reading of

10±.01vdc.

Step 3. Reinstall the cover and 4 mounting screws.

2.3. MAGNEHELIC GAUGE ZERO CALIBRATION

2.3.1. Zero Calibration

Step 1. With no pressure applied, verify magnehelic gauge reads zero on the meter face. If

not, use a small slotted screw driver and adjust the slotted screw located at the end

of the indicating needle until a zero reading is achieved.