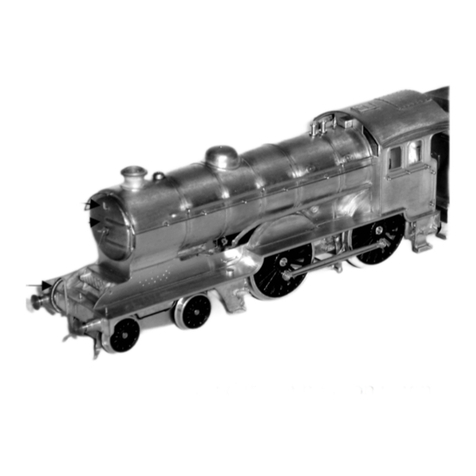

42xx/72xx Instructions Raised running plate.

Note that these instructions cover the 72xx. Construction of the 42xx is identical apart from the

position of the rear body – chassis fixing point and the shorter bunker. The rear pony truck is

not in the 42xx.

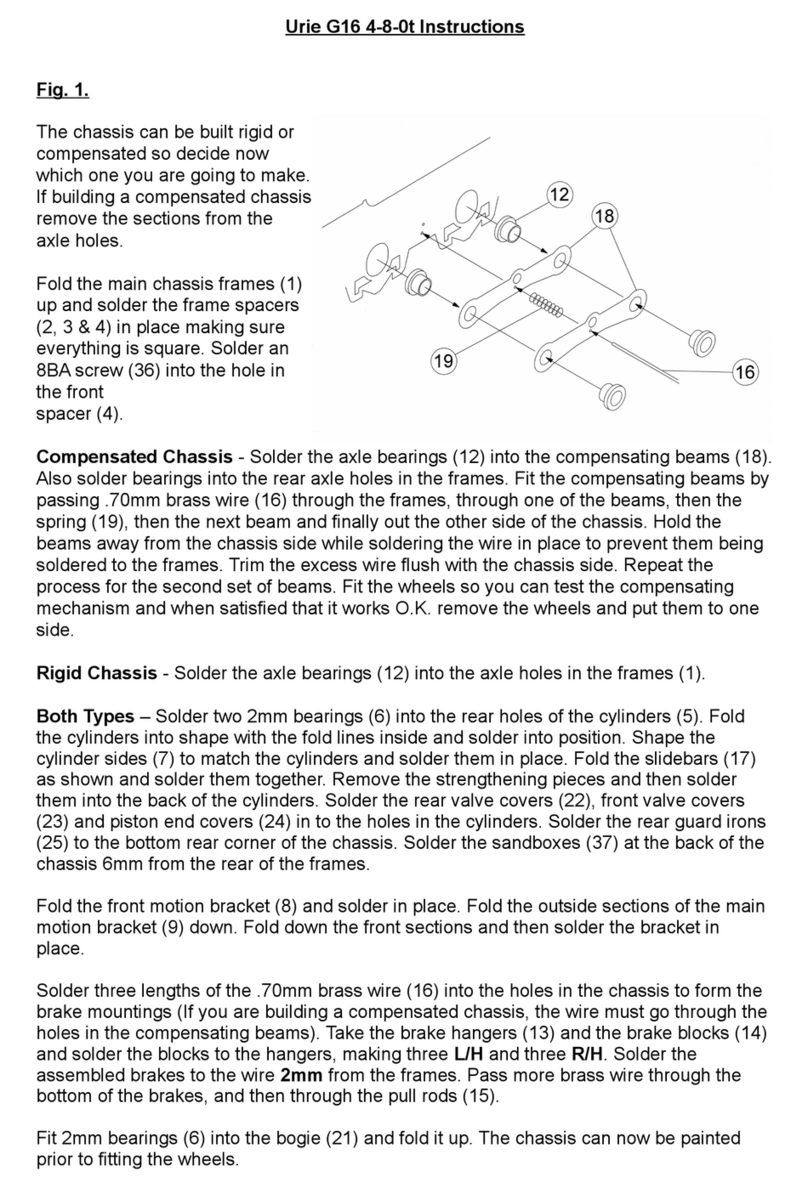

Fig. 1.

Chassis Assembly

The chassis can be built rigid or compensated so decide now which one you are going to

make. If building a compensated chassis remove the sections from the axle holes.

Fold the main chassis frames (1) up and solder the rear frame spacer (2), centre spacer (3)

and front spacer/pony mount (4) in place making sure everything is square. Solder a 10BA

screw (8) into the hole in the pony truck mount and another into the hole in the rear stretcher

from underneath.

Compensated Chassis - Solder the axle

bearings (9) into the compensating beams

(7). Fit the compensating beams by passing

brass wire through the frames, through one

of the beams, then one of the springs, then

the next beam and finally out the other side

of the chassis. Hold the beams away from

the chassis side while soldering the wire in

place to prevent them being soldered to the

frames. Repeat for the second set of beams

and then trim the excess wire flush with the

chassis side. Fit the wheels so you can test

the compensating mechanism and when

satisfied that it works O.K. remove the wheels and put them to one side.

Rigid Chassis - Solder the axle bearings (9) into the axle holes in the chassis (1).

Take the cylinders (5) and curve the bottom of the cylinder sides to match the shape of the

cylinder front/rear. Fold down the front and rear and the sides and solder around the seams.

Fit the cylinders into the recess at the front of the frames.

Solder four lengths of the brass wire (10) into the holes in the chassis to form the brake

mountings. Take the brake hangers (11) and the brake blocks (12) and solder the blocks to the

hangers, making four L/H and four R/H. Solder the assembled brakes to the wire 2mm from

the frames. Pass more brass wire through the bottom of the brakes and then through the pull

rods (13). Solder all the joints. Refer to the inset drawing and assemble the brake actuating

rods and levers (14 & 15).

Solder the cylinder drain cocks (21) under the cylinders. Assemble the front pony truck (17 &

18) and the rear pony truck (22 & 23). Solder or glue the sandboxes (24) into their holes at the

rear of the chassis. Make up the sandpipes with brass wire and fit into the bottom of the