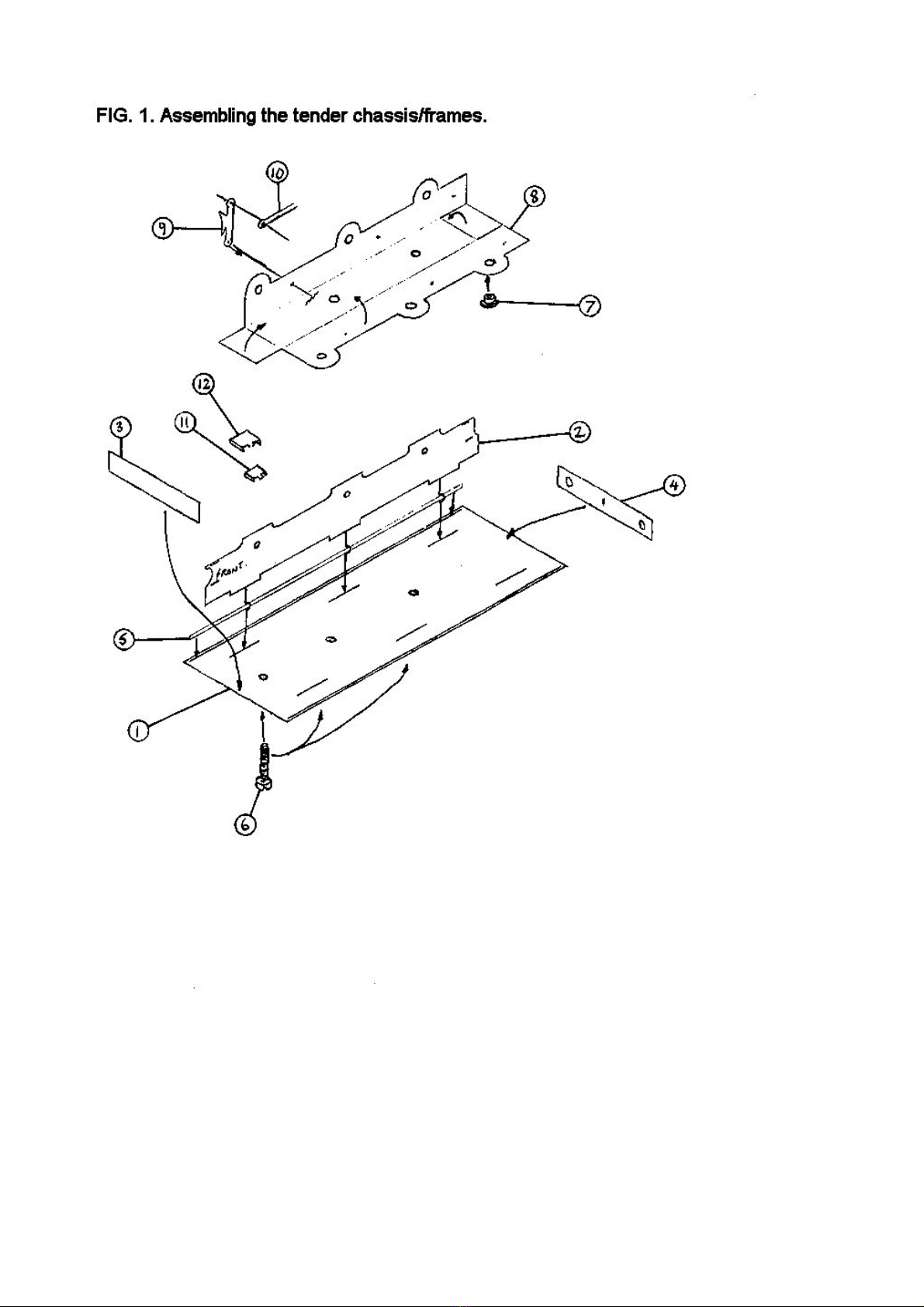

mainframe. Both beams must move independently of each other. The assembly of the beams

is otherwise very simple. Make sure you fit the beams so that the large hole is over the rear

brake pilot hole. it the wheels (to the bogie and chassis) so you can test the compensating

mechanism. it the bogie spacer (13) and then the bogie and when satisfied that all works

O.K. remove the wheels and the bogie and put them to one side.

BRAKE ASSEMBLY

Solder two lengths of the brass wire (6) into the holes in the chassis to form the brake

mountings (take care not to get solder on the compensation mechanism). Take the brake

hangers (8) and the brake block overlays (9) and solder the overlays onto the hangers. Solder

the assembled brakes to the wire 2mm from the frames. Pass more brass wire through the

bottom of the brakes and then through the brake rods (7) and solder the joints.

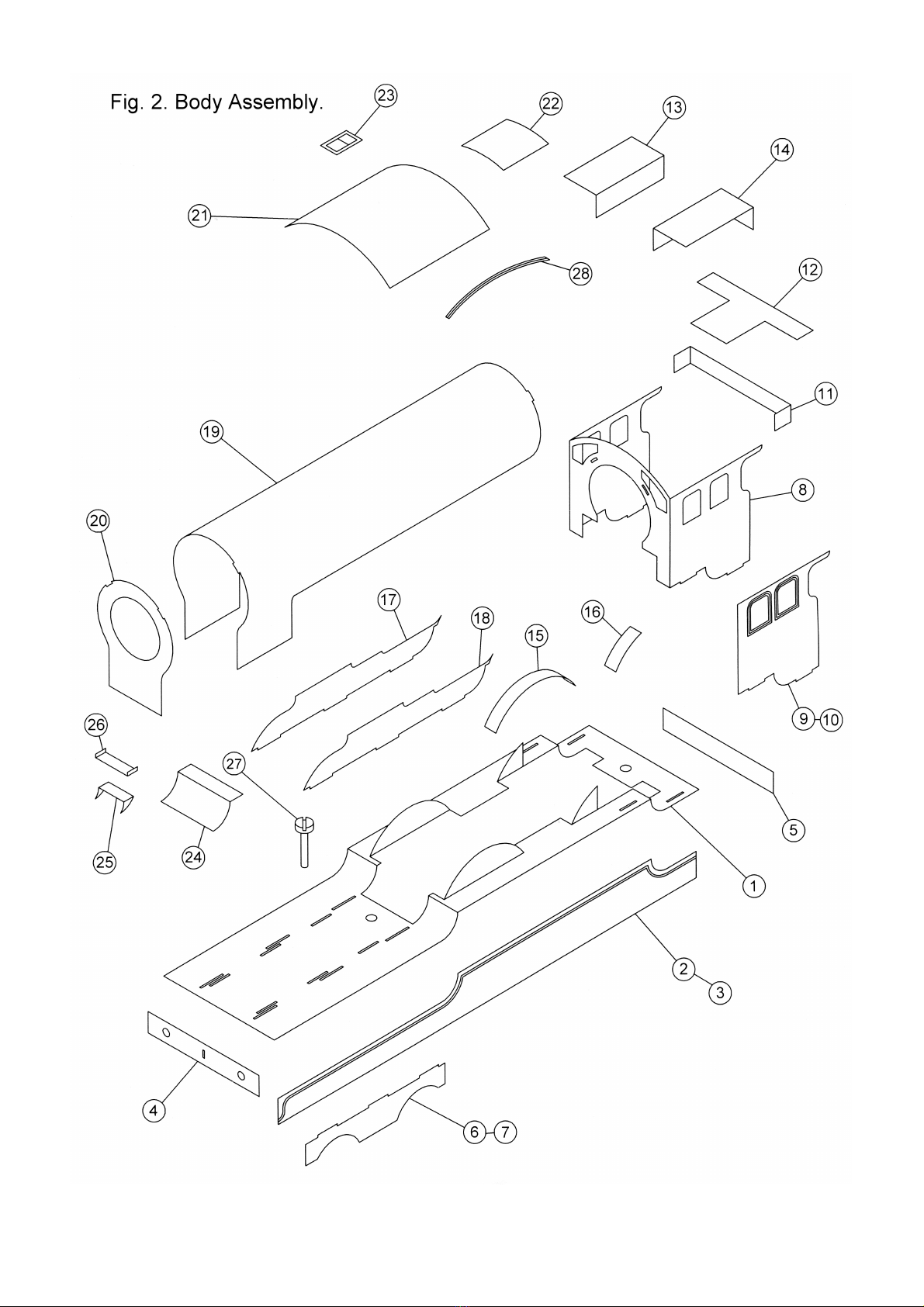

BODY ASSEMBLY

Take the running plate (1) and fit the valances (2 & 3) into the recesses under the running

plate. it the buffer beam (4) into the recess at the front of the running plate and the rear drag

beam (5) into the recess at the rear. it the lower front frame sections (6 & 7) under the

running plate. old the splashers up. Leave the valance supports in position until the boiler has

been fitted.

Take the cab etching (8) and fold the cab sides at 90° to the cab front. Check the fit of this into

the slots and when satisfied with the fit solder it in place. Curve the splasher tops (15 & 16)

and solder them onto the splasher sides.

Take the frame tops (17 or 18). Solder them into the slots in the running plate. Solder three

8BA screws (27) into the holes in the running plate.

orm the cab floor support (11) and fit between the cab sides, with a 1mm gap between it and

the rear of the running plate. Solder the cab floor (12) on top of the support. orm the interior

cab splashers (13 & 14) and solder them to the cab floor.

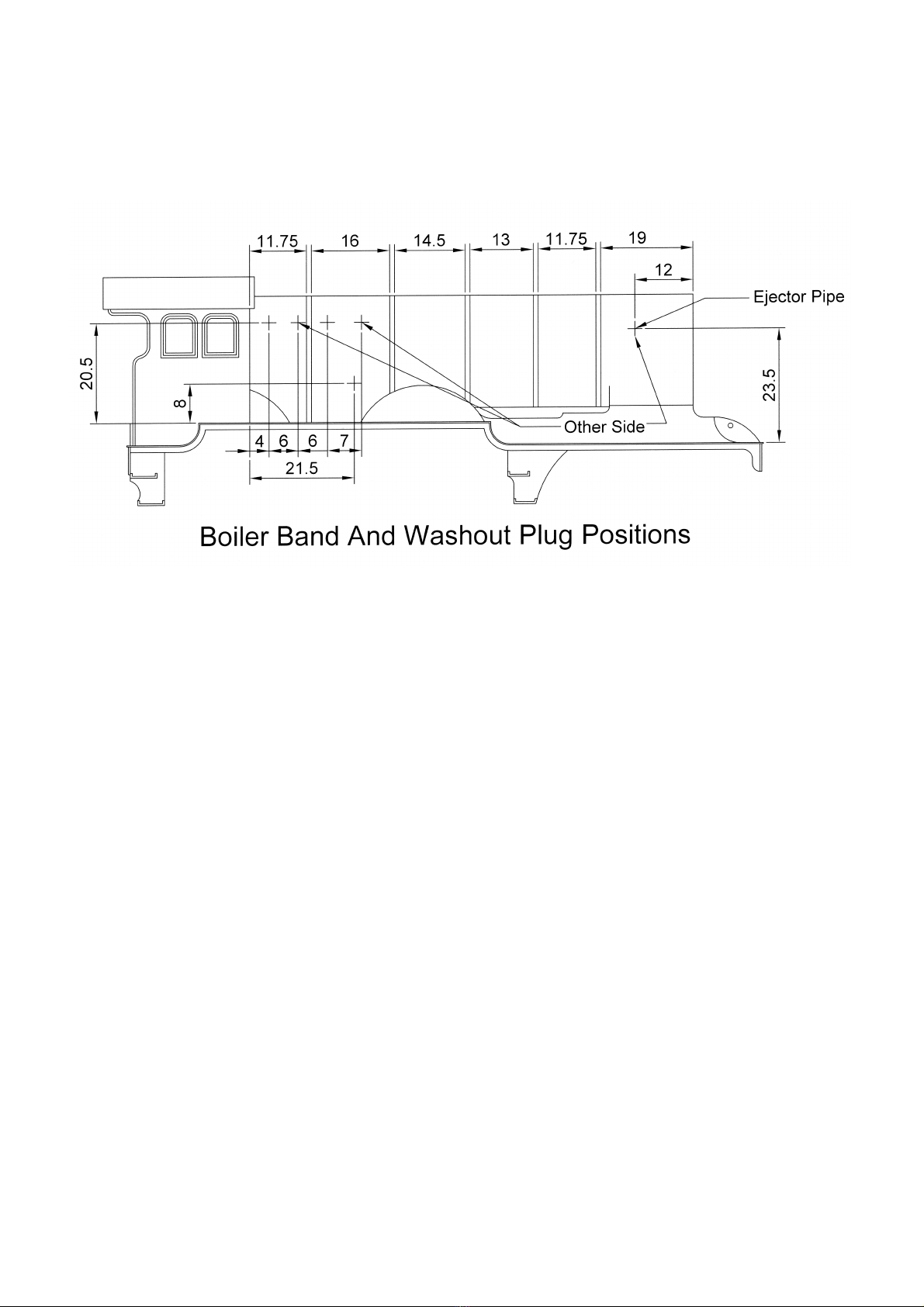

Now turn to the boiler (19). Solder the seam together. orm the bottom of the smokebox to

match the profile of the smokebox front. Solder the smokebox front (20) to the boiler, the tabs

on the boiler fit into the recesses on the smokebox front. it the boiler bands (28) now [see ig.

2a.]. Now check the fit of the boiler into the slots in the cab front. Tack it in place and when

satisfied that all is level solder both boiler and firebox firmly in place. Curve the cylinder cover

(24), check the fit between the frames and solder in place.

Solder the cab side overlays (9 & 10) in place. orm the cab roof (21) and tack it in place. The

front of the roof overhangs the cab front and the sides, when all is square solder around the

seams. Solder the rain strips (28) in place. Solder the roof vent (23) and the riveted plate (22)

in place.

Now remove the valance supports.

old the top of the cab steps (29) and running plate steps (30) over. old the bottom step up

as well and run some solder into the fold for strength. Solder them in place under the running

plate and against the valance. Solder the small steps into the slots.