Peaco Support FC280 Series User manual

m(General Purpose)

m(Elevator & Lift Series)

m( Off Grid Solar Series)

m(220V Input, 380V Output Series)

m(Single Phase Output Series)

Peaco Support FC280 Series VFD User Manual

VFD

PEACO SUPPORT

Preface

Thank you for purchasing the AC drive developed by Our company.

AC drives are general type inverters with vector control based on BD330.High

quality, multiple functions and low noise, developed independently by ourselves.

It can realize open loop and close loop control of different mode,and also signal

detection of PT100/PT1000 motor temperature.It support speed sensorless vec-

tor control,sensor vector control and V/F control.Performance of motor control

has beed improved obviously.Easy operation,perfect self-learning of motor static

and dynamic state.

AC drives are compact structure, easy installation, and reasonable heat dissipa-

tion design ,that ensure reliability of product. Various of expansion cards are ava-

ilable for your choice.

We provide information of model selection, installation, parameter setting, field

debugging, fault diagnosis and daily maintenance for users in this manual.

ATTENTIONS

Ø

Ø

Ø

Ø

Ø

Please power off when wiring.

Electronic components inside AC drive are especially sensitive to static

electricity, do not put anything into internal of AC drive.And do not touch

main circuit board.

After power cut, if indicator is still lamp, it still have high voltage in AC

drive. It is very dangerous, please do not touch internal circuit and

components.

Please ensure the grounding terminals of AC drive is grounded correctly.

Never connect input power supply with output terminal U,V,W of AC drive.

First-time Use

For the users who use this product for the first time, read the manual carefully. If

in doubt concerning some functions or performances, contact the technical sup-

port personnel of Our company to ensure correct use.

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Contents

-2-

Chapter 1 Safety and Attentions

1.1 Safety Matters.................................................................................................6

1.2 Use Considerations........................................................................................9

Chapter 3 Installation

3.1 Mechanical installation..................................................................................22

3.2 Electrical Installation......................................................................................23

3.3 Basic wiring diagram.....................................................................................26

3.4 Jumper function declaration of main board...................................................27

3.5 Main circuit terminals and connection...........................................................27

3.6 Control circuit terminal and wirin...................................................................29

3.7 Treatment of EMC problem...........................................................................32

Chapter 2 Product Brief Introduction

2.1 Position and content of nameplate................................................................12

2.2 Nameplate model description and rated parameters....................................12

2.3 Specifications and models of AC drives........................................................13

2.4 Technical Features........................................................................................15

2.5 All components schematic diagram of AC drive............................................17

2.6 Dimensions....................................................................................................18

Chapter 4 Operation and Display

4.1 Keypad description........................................................................................36

4.2 Function code examining and modifying methods explanation.....................38

4.3 How to view status parameters.....................................................................40

4.4 Password setting...........................................................................................40

4.5 Self-learning of motor parameters ( when vector control function)................41

Chapter 5 Function & Parameter Table

5.1 How to read the parameter list......................................................................44

5.2 Functional group............................................................................................45

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

-3-

F00 Standard Function Parameters........................................................... 86

F01 Standard Function Parameters....................................................98

F02 Motor 1 Parameters...................................................................104

F03 Vector Control Parameters........................................................108

F04 V/F Control Parameters.............................................................114

F05 Fault and Protection..................................................................120

F06 Input Terminals.........................................................................131

F07 Output Terminals.......................................................................146

F08 Keypad And Display..................................................................152

F09 Auxiliary Functions....................................................................157

F10 Process Control PID Function....................................................172

F11 Swing Frequency, Fixed Length and Count................................180

F12 Simple PLC Function And Multi-speed control............................183

F13 Communication Parameters......................................................188

F15 Motor 2 Parameters...................................................................190

Chapter 7 Fault Diagnosis and Trouble Shooting

7.1 Faults and Solutions....................................................................................192

7.2 Common Faults and Solutions....................................................................198

Appendix A: Serial Communications..................................................................202

Appendix B: Accessories Selection....................................................................212

Appendix C: Mini Series introduction.................................................................216

Appendix D: Single Phase Output Series...........................................................219

Appendix E: 220V Input, 380V Output Series....................................................221

Appendix F: Elevator & Lift Series......................................................................223

Appendix G: Off Grid Solar Series.....................................................................229

Chapter 6 Description of Function Codes

Warranty

Warranty Card

Certificate of quality

Chapter 8 Appendix

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Safety and Attentions

Chapter 1

1.1 Safety Matters.................................................................................................6

1.2 Use Considerations........................................................................................9

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 1 Safety and Attentions

-6-

1.1 Safety Matters

Use Stage Safety Grade Precautions

Before

Installation

²Do not install the product if the package is with water,

or component is missing or broken;

²Do not install the product if the label on the package is

not identical to that on the inverter.

²Be careful of carrying or transportation. Risk of devices

damage;

²Do not use damaged product or the inverters missing

component .Risk of injury;

²Do not touch the parts of control system with bare

hands. Risk of ESD hazard.

²Installation base shall be metal or other non-flammable

material. Risk of fire;

²Do not install inverter in an environment containing

explosive gases, otherwise there is danger of explosion;

²Do not unscrew the fixing bolts, especially the bolts with

red mark.

Installation

CAUTION

DANGER

DANGER

²Do not leave cable strips or screws in the inverter. Risk

of inverter damage;

²Install the product at the place with less vibration and

no direct sunlight;

DANGER

Safety signs in this manual

DANGER Dangers caused by operations beyond requirements

may lead to serious injury,and even death.

CAUTION

angers caused by operations beyond requirements

may lead to moderate damages or minor injuries, as

well equ-ipment damages.

Users are requested to read this chapter carefully when installing, commissioni-

ng and repairing this product and perform the operation according to safety

precautions as set forth in this chapter without fail. Our company will bear no

responsibility for any injury and loss as a result of any violation operation.

Chapter 1

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 1 Safety and Attentions

²Consider the installation space for cooling purpose when

two or more inverters are placed in the same cabinet.

DANGER

Installation

Use Stage Safety Grade Precautions

Wiring

²Wiring must be performed by authorized and qualified

personnel. Risk of danger;

²Circuit-breaker should be installed between inverter

and the mains. Risk of fire;

²Make sure the input power supply has been completely

disconnected before wiring. Failure to comply may

result in personnel injury and/or equipment damage;

²Since overall leakage current of this equipment may be

bigger than 3.5mA, for safety's sake, this equipment

and its associated motor must be well grounded so as

to avoid risk of electric shock;

²Never connect the power cables to the output terminals

(U,V,W) of the AC drive. Pay attention to the marks of

the wiring terminals and ensure correct wiring. Failure

to comply will result in damage to the AC drive;

²Install braking resistors at terminals (P+)and (P- or PB)

only. Failure to comply may result in equipment

damage.

²Since all adjustable frequency AC drives from Our

company have been subjected to hi-pot test before

delivery, users are prohibited from implementing such a

test on this equipment. Failure to comply may result in

equipment damage.

²Signal wires should to the best of the possibility be

away from main power lines. If this cannot be ensured,

vertical cross-arrangement shall be implemented,

otherwise interference noise to control signal may

occur.

²If motor cables are longer than 100m, it is recommend-

ed output AC reactor be used. Failure to comply may

result in faults.

CAUTION

DANGER

²Inverter shall be power-on only after the front cover is

assembled. Risk of electrical hazard.

DANGER

Before

Power-on ²Verify that the input voltage is identical to the rated

voltage of product, correct wiring of input terminals R,

CAUTION

-7-

Chapter 1

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Before

Power-on

S, T or L1, L2 and output terminals U, V, and W, wiring of

inverter and its peripheral circuits, and all wires should

be in good connection. Risk of inverter damage.

CAUTION

Use Stage Safety Grade Precautions

²Do not open the cover after power. Rick of electrical

hazard;

²Do not touches any input/output terminals of inverter

with bare hands. Rick of electrical hazard.

DANGER

After

Power-on ²If auto tuning is required, be careful of personal injury

when motor is running. Risk of accident;

²Do not change the defaults of parameters. Risk of

devices damage.

CAUTION

²Non-professionals shall not detect signals during

operation. Risk of personal injury or device damage;

²Do not touch the fan or the discharging resistor to

check the temperature. Failure to comply will result in

personal burnt.

DANGER

During

Operation

²Prevent any foreign items from being left in the devices

during operation. Risk of device damage;

²Do not control start/stop of inverter by ON/OFF of

contactor. Risk of device damage.

CAUTION

²Please do not make repair and maintenance over equ-

ipment in a charged state, or it will give rise to electric

shock hazard!

²AC drive can be put into maintenance and repair only

you confirm the AC drive charge light out, or the rema-

ining electric charge of capacitance will cause damages

to people!

²Any people who are not trained professionally cannot

make repair and maintenance, or it will cause personal

injuries or equipment troubles!

DANGER

Main-

tenance

-8-

Chapter 1 Safety and Attentions

Chapter 1

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

-9-

1.2 Use Considerations

1.2.1 Motor Insulation Inspection

When the motor is used for the first time or when the motor is reused after being

kept, or when periodical inspection is performed, insulation inspection shall be

conducted with motor so as to avoid damaging the inverter because of the

insulation failure of the motor windings. The motor wires must be disconnected

from the inverter during the insulation inspection. It is recommended to use the

500V mega meter, and the insulating resistance measured shall be 5MΩ at least.

1.2.2 Motor Thermal Protection

If the motor rating does not match that of the inverter, especially when the rated

power of the inverter is higher than that of the motor, adjust motor protection

parameters in the inverter or install thermal relay to protect motor.

1.2.3 Operating with the Frequency Higher than Grid Power Frequency

Output frequency of is 0.00Hz~500Hz. If is required to operate above

50.00Hz, please take the endurance of mechanical devices into consideration.

product

1.2.4 Mechanical Vibrations

Inverter may encounter mechanical resonance point of the load device at certain

output frequencies which can be avoided by setting the skip frequency paramet-

ers of the inverter.

1.2.5 Motor Heat and Noise

Since output voltage of inverter is PWM wave and contains a certain amount of

harmonics, so that the temperature, noise and vibration of the motor will be

higher than those when the inverter runs at grid power frequency.

1.2.6 Voltage-sensitive device or capacitor on output side of the AC drive

Do not install the capacitor for improving power factor or lightning protection

voltage-sensitive resistor on the output side of the AC drive because the output

of the AC drive is PWM wave. Otherwise, the AC drive may suffer transient

overcurrent or even be damaged.

1.2.7 Contactor at the I/O terminal of the AC drive

When a contactor is installed between the input side of the AC drive and the pow-

er supply, the AC drive must not be started or stopped by switching the contactor

on or off. If the AC drive has to be operated by the contactor, ensure that the time

interval between switching is at least one hour since frequent charge and discha-

rge will shorten the service life of the capacitor inside the AC drive;

Chapter 1 Safety and Attentions

Chapter 1

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

-10-

When a contactor is installed between the output side of the AC drive and the

motor, do not turn off the contactor when the AC drive is active. Otherwise,

modules inside the AC drive may be damaged.

1.2.8 Applied with the Rated Voltage

Apply with the rated voltage. Failure to comply will damage inverter. If

required, take a transformer to boost or step-down voltage.

product

1.2.9 Do Not Apply a 3-Phase Input Inverter to 2-Phase Input Applications

Do not apply a 3-phase input FR inverter to 2-phase input applications. Otherwise,

it will result in faults or damage inverter.

1.2.10 Lightning Protection

The product

certain self-protection capacity against the lightning. Additional protection devices

have to be installed between inverter and power supply in the area where lightning

occurs frequently.

has integrated lightning over-current protection device which has

1.2.11 Altitude De-rating

In places where the altitude is above 1000 m and the cooling effect reduces due

to thin air, it is necessary to de-rate the AC drive. Contact Our company for

technical support.

1.2.12 Adaptable Motor

Standard adaptive motor is quadrupole squirrel- cage asynchronous induction

motor. If it is not above- mentioned motor, please select AC drive upon rated

current of moter. If you need to drive permanent magnet synchronous motor,

please consult our company;

The cooling fan of non variable frequency motor and rotor spindle are coaxially

connected. While despinning, the fan cooling effect also declines at the same

time.Hence, for overheated occasion of moter, you shall install strong exhaust

fan or change variable frequency motor;

AC drives have built- in adaptive motor standard parameters. It is necessary to

make motor parameter identification or amend default values to accord with

actual values, or it will influence operation effects and protective values;

As short circuit existing inside cable or motor will cause inverter alarming,

enen explosion. Therefore, please make insulation short- circuit test of initial

installed motor and cable first. And the test also is necessary in routine

maintenance.

Chapter 1 Safety and Attentions

Chapter 1

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Product Brief Introduction

Chapter 2

2.1 Position and content of nameplate................................................................12

2.2 Nameplate model description and rated parameters....................................12

2.3 Specifications and models of AC drives........................................................13

2.4 Technical Features........................................................................................15

2.5 All components schematic diagram of AC drive............................................17

2.6 Dimensions....................................................................................................18

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 2 Product Brief Introduction

2.1 Position and content of nameplate

2.2 Nameplate model description and rated parameters

1

1.5 G

5

2 3

4 T - - B

4

No. Content

Code

Voltage Classification

Model

Accessory type

Adapted motor powe

Heavy-duty

Brake unit

S Single- T Three phase:phase :

5

4

3

2

1

Voltage level 2:220V 4 380V:

0.75KW~630KW

MOD L: 4T-1.5G-B

SOURCE:

OUTPUT: 1.5KW 4A

E

PH AC380V 50/60HZ

0-600HZ

BDDG3DFDF122466

-12-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 2 Product Brief Introduction

2.3 Specifications and models of AC drives

Input 1PH 220V±15% 47Hz~63Hz

2S-0.5G-B 0.55 5.4 4.0 0.55

2S-0.7G-B 0.75 8.2 5.0 0.75

2S-1.5G-B 1.5 14.0 7.0 1.5

2S-2.2G-B 2.2 23 10.0 2.2

Input 3PH 220V±15% 47Hz~63Hz

2T-0.5G-B 0.55 3.8 3.2 1.5

2T-0.75G-B 0.75 4.9 4.1 0.75

2T-1.5G-B 1.5 8.4 7.0 1.5

2T-2.2G-B 2.2 11.5 10.0 2.2

2T-3.7G-B 3.7 18 15 3.7

2T-5.5G-B 5.5 24 23 5.5

2T-7.5G-B 7.5 37 31 7.5

2T-11G-B 11 52 45 11

2T-15G-B 15 68 58 15

2T-18.5G-B 18.5 84 71 18.5

2T-22G-B 22 94 85 22

2T-30G 30 120 115 30

2T-37G 37 160 145 37

2T-45G 45 198 180 45

2T-55G 55 237 215 55

2T-75G 75 317 283 75

Input 3PH 380V±15% 47Hz~63Hz

4T-0.75G/1.5P 0.75/1.5 3.4/5.0 2.5/3.7 0.75/1.5

4T-1.5G/2.2P 1.5/2.2 5.0/5.8 3.7/5.0 1.5/2.2

4T-2.2G/3.7P 2.2/3.7 5.8/10.5 5.0/8.5 2.2/3.7

4T-3.7G/5.5P 3.7/5.5 10.5/14.6 8.5/13 3.7/5.5

4T-5.5G/7.5P 5.5/7.5 14.6/20.5 13/18 5.5/7.5

4T-7.5G/11P 7.5/11 20.5/26 18/24 7.5/11

Adaptive

motor (KW)

Rated output

current(A)

Rated input

current (A)

Rated power

(KW)

Models

-13-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 2 Product Brief Introduction

Input 3PH 380V±15% 47Hz~63Hz

4T-11G/15P 11/15 26/35 24/30 11/15

4T-15G/18.5P 15/18.5 35/38.5 30/37 15/18.5

4T-18.5G/22P 18.5/22 38.5/46.5 37/46 18.5/22

4T-22G/30P 22/30 46.5/62 46/58 22/30

4T-30G/37P 30/37 62/76 58/75 30/37

4T-37G/45P 37/45 76/92 75/90 37/45

4T-45G/55P 45/55 92/113 90/110 45/55

4T-55G/75P 55/75 113/157 110/150 55/75

4T-75G/93P 75/93 157/180 150/170 75/93

4T-93G/110P 93/110 180/214 170/210 93/110

4T-110G/132P 110/132 214/256 210/250 110/132

4T-132G/160P 132/160 256/307 250/300 132/160

4T-160G/200P 160/200 307/385 300/380 160/200

4T-200G/220P 200/220 385/430 380/430 200/220

4T-220G/250P 220/250 430/468 430/465 220/250

4T-250G/280P 250/280 468/525 465/520 250/280

4T-280G/315P 280/315 525/590 520/585 280/315

4T-315G/350P 315/350 590/665 585/650 315/350

4T-350G/400P 350/400 665/785 650/754 350/400

4T-400G/500P 400/500 785/965 754/930 400/500

4T-500G/630P 500/630 965/1210 930/1180 500/630

4T-630G/710P 630/710 1210/1465 1180/1430 630/710

Adaptive

motor (KW)

Rated output

current(A)

Rated input

current (A)

Rated power

(KW)

Models

-14-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

2.4 Technical Features

Power input

Technical Features Description

Input voltage range 1AC 220V±15%, 3AC 220V±15%,3AC 380V±15%, 3AC

660V±10%, 3AC 1140V±15%

Input frequency range 47~63Hz

Power factor ≥95%

Control performance

Control mode V/F control, non-PG vector control(SVC),PG vector control

(FVC)

V/F control Line, multiple point , square V/F curve, V/F separation

Operation command

mode

Keypad control, Terminal control, Serial communic-ation

control

Frequency Reference

Source

Digital,analog,pulse frequency,serial communication, multi-

step speed,simple PLC and PID The combinaton of multi-

modes and the different modes can be switched.

Overload capacity G type: 150% rated current 60s,180% rated current 3s

P type: 120% rated current 60s, 150% rated current 3s

Start torque G type: 0.5Hz/150%(SVC), 0Hz/180%(FVC)

P type: 0.5Hz/100%

Speed adjusting range 1:100(SVC) 1:1000(FVC)

Speed control

accuracy ±0.5%(SVC) ±0 . 02%( FVC)

Carrier frequency 0.5 to 16.0kHz;automatically adjust carrier frequency

according to the load characteristics

Frequency resolution Digital setting:0.01Hz. Anolog setting:maximum frequency x

0.025%

Torque boost Automatic torque boost; manual torque boost 0.1~30%

Acceleration and

deceleration mode

Line or S-curve, 4 types of acceleration/deceleration time

with the range of 0.0~6500.0 s

DC brake Supports starting and stopping DC brake;

Jogging Control Jog frequency range:0.0Hz~50.00Hz; Jog Acc/Dec

time:0~6500.0s

Simple PLC & multi

step speed operation Built-in PLC or control terminal,16 steps speed can be set

Built-in PID

Built-in PID control to easily realize the close loop control for

the process parameters (such aspressure, temperature,

flow, etc.)

Chapter 2 Product Brief Introduction

-15-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 2 Product Brief Introduction

Technical Features Description

Control performance

Automatic voltage

regulation(AVR)

Automatically maintain a constant output voltage when the

voltage of electricity grid changes

Common DC bus Common DC bus function: multiple inverters can use a

common DC bus

Traverse control Traverse control function:multiple triangular pulse

frequency control

Fixed length control Setting length control

Timing control Setting time range:0~6500min

Main control

Input terminals

6 programmable digital inputs,it can be extended to 4 digital

inputs,one of which supports high speed pulse input;

1 analog volatge input 0~10VDC;

2 volatge input 0~10VDC or current input 0~20mA.

Output terminals

1 open collector output ,it can be extened to 1 high speed

pulse output ;

2 relay outputs ;

2 analog output: volatge output 0~10VDC or current output

0~20mA.

Human

machine

interface

LED Display Can display setting frequency, output frequency, output

voltage, output current, etc.

Enviorment

& Protection class

Protection class IP20

Humidity &

temperature

90%RH or less (no-condensation),- 10℃~ +40℃.Inverter

will be derated if ambien temperature exceeds 40℃

Vibration Under 20Hz 9.8m/s(1G),Over 20Hz5.88m/s(0.6G)

Store environment ≤1000M,indoor(no corrosive gas and liquid)

Store temperature - 20℃~ 60℃

Cooling Mode Forced air-cooling

-16-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

-17-

Chapter 2 Product Brief Introduction

2.5 All components schematic diagram of AC drive

The following picture is all components and names of below 22KW plastic shell

AC drive.

4

5

6

7

8

10

11

9

1

2

3

No. Name Description

❶Cabinet-cover Protect the internal components.

❷Keypad Refer to chapter4 "Keypad operating procedures."

❸Lower-cover Protect the internal components.

❹Fan-cover Protection fan.

❺Lower House Including Fan and heat sink

❻Middle House Including Power Boards

❼Dust prevention To Prevent Dust

❽Bottom Board Inverter protection

❾Apron Convenient input and output wiring.

❿Series Label Refer to 2.3 "Naming Rules".

⓫Screw Hole To make VFD firm with screw

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

Chapter 2 Product Brief Introduction

D

W

A

B

H

2.6 Dimensions

D

W

A

d

B

H

A

W

D

B

d

H

Plastic case and wall mount case

Wall/Cabinet Combination Chassis

AC Drive Model Rated Power

(KW)

A

(mm)

H

(mm)

D

(mm)

W

(mm)

B

(mm)

d

(mm)

Input 1PH 220V±15% 47Hz~63Hz

2S-0.5G-B 0.55

118 185 157 106 175 4.5

2S-0.7G-B 0.75

2S-1.5G-B 1.5

2S-2.2G-B 2.2

160 247 177 148 235 5.52S-3.7G-B 3.7

2S-5.5G-B 5.5

-18-

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

-19-

Chapter 2 Product Brief Introduction

Input 3PH 380V±15% 47Hz~63Hz

4T-0.7G/1.5P-B 0.75/1.5

118 185 157 106 175 4.5

4T-1.5G/2.2P-B 1.5/2.2

4T-2.2G/4.0P-B 2.2/3.7

4T-4.0G/5.5P-B 3.7/5.5

4T-5.5G/7.5P-B 5.5/7.5

160 247 177 148 235 5.5

4T-7.5G/11P-B 7.5/11

4T-11G/15P-B 11/15

4T-15G/18.5P-B 15/18.5

220 321 198 205 305 5.54T-18.5G/22P-B 22/30

4T-22G/30P-B 30/37

AC Drive Model Rated Power

(KW)

A

(mm)

H

(mm)

D

(mm)

W

(mm)

B

(mm)

d

(mm)

4T-30G/37P 37/45 220 411 238 160 395 7

4T-37G/45P 45/55

4T-45G/55P 55/75 255 453 237 190 440 7

4T-55G/75P 75/93 280 582 295 200 563 9

4T-75G/90P 93/110

4T-90G/110P 110/132 300 685 323 200 667 11

4T-110G/132P 132/160

4T-132G/160P 160/200 360 690 330 260 660 11

4T-160G/185P 200/220 420 840 334 150*

150 815 11

4T-185G/200P 220/250

4T-200G/220P 250/280

540 934 390 200*

200 893 13

4T-220G/250P 280/315

4T-250G/280P 315/350

4T-280G/315P 350/400 640 1035 390 250*

250 1003 11

4T-315G/350P 400/500

4T-350G/400P 500/630 860 1200 400 350*

350 1164 15

4T-400G/450P 630/710

Chapter 2

Peaco Support FC280 Series VFD User Manual

PEACO SUPPORT

This manual suits for next models

45

Table of contents

Popular DC Drive manuals by other brands

SOMFY

SOMFY Sonesse 50 RTS Operating and installation guide

Danfoss

Danfoss VLT HVAC FC 100 instruction manual

Danfoss

Danfoss VLT HVAC Drive FC 102 installation guide

SOMFY

SOMFY sonesse 30 rts instructions

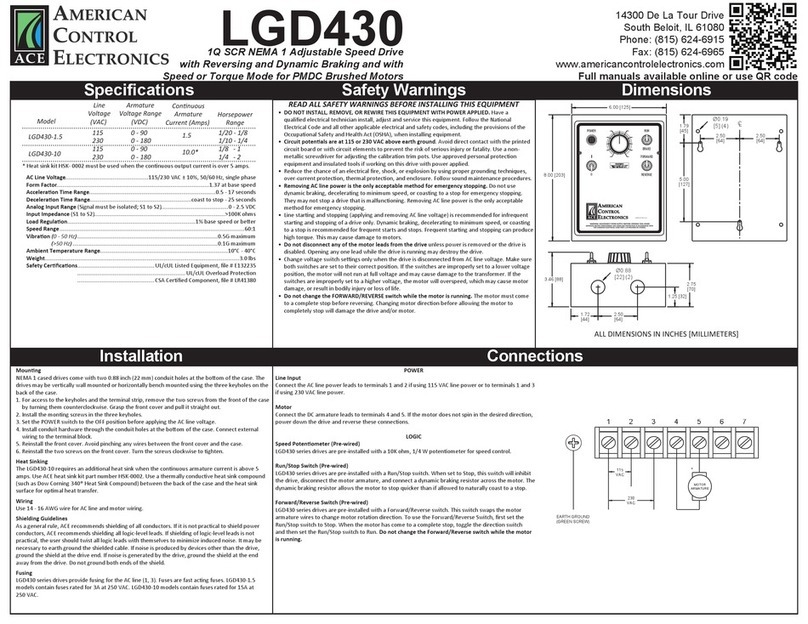

American Control Electronics

American Control Electronics LGD430 manual

SEW-Eurodrive

SEW-Eurodrive MOVIMOT advanced DRN DBC Series operating instructions

i-MO

i-MO HD2-3.7A-43 instruction manual

Danfoss

Danfoss VLT FC 103 operating instructions

YASKAWA

YASKAWA E7 Drive installation guide

Nord Drivesystems

Nord Drivesystems SK 500E Series Brief instructions

BIAX

BIAX MB 20/2 Translation of the original operating manual

EUCHIPS

EUCHIPS EUP75D-1H12V-0 quick start guide