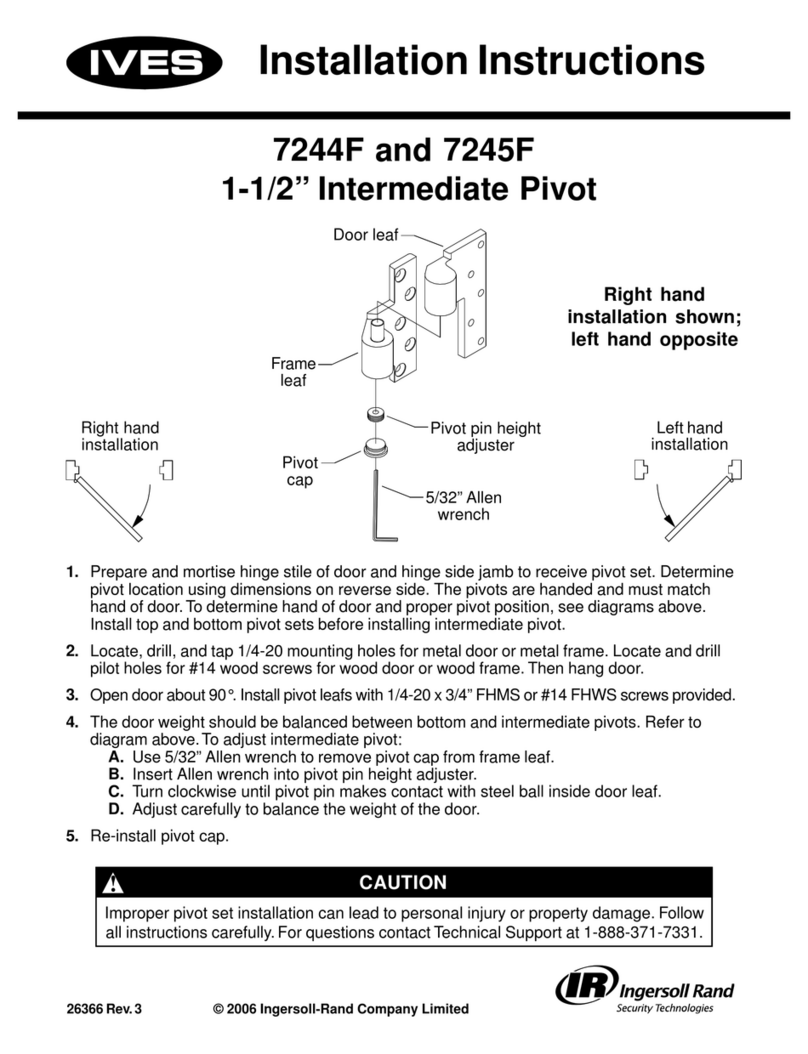

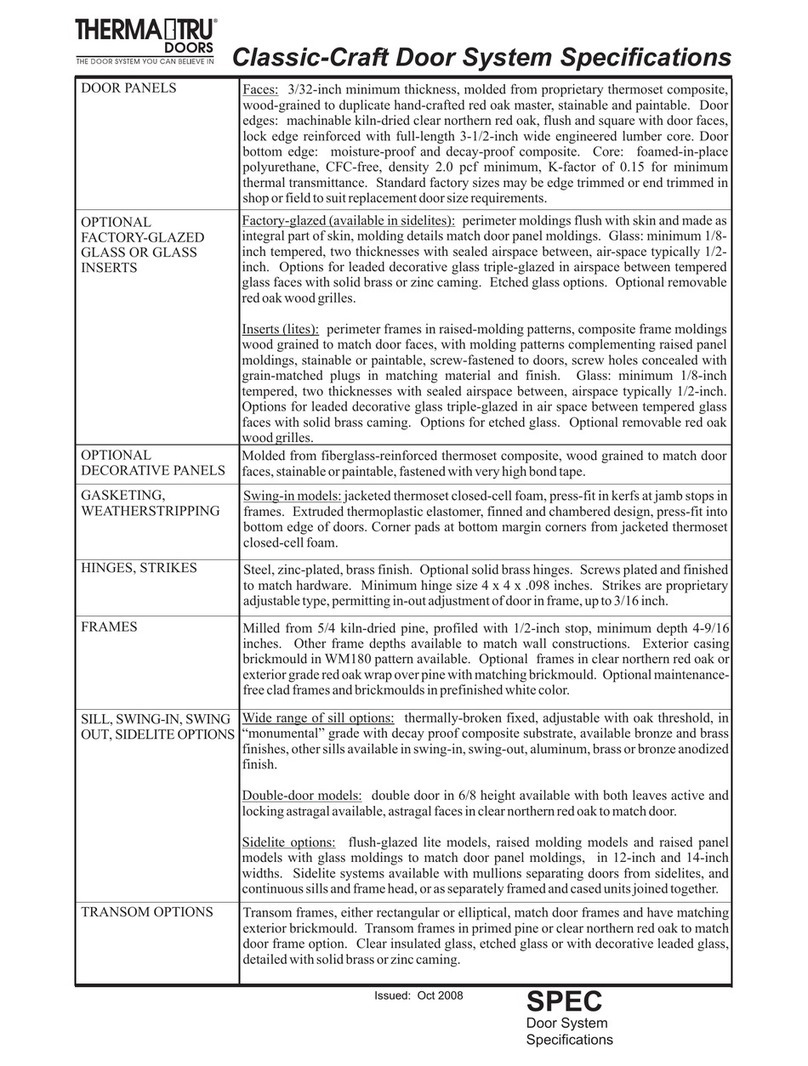

N. For Doors with adjustable hinges: The hinges can be used to move the panel side

to side by moving all hinges in the same direction or the hinges can slightly rotate the

panel by adjusting the hinges in opposite directions. Use a T20 Torx wrench to turn

the center screw clockwise (+) to increase the space between the hinge side of the

frame and door panel. Turn the center screws counter-clockwise (-) to decrease the

space between the hinge side of the frame and the door panel .

Note: Do not adjust the hinge with the top and bottom screws loose; this could

force the hinge to adjust beyond its design capability which can cause the hinge

to bind, damage the hinge and/or pull out the screws. A 3/4 turn of the center

screw provides approximately 5/32" adjustment.

O. On doors with a lock strike in the

side, drill a 1/8" diameter x 2" deep

pilot hole into the rough opening

through the two pre-drilled holes in

the frame. One pre-drilled frame hole

is located in the center lock strike

hole and the other is the upper frame

corner installation hole approximately

8" from the top of the door frame

head. Insert a #8 x 3" screw (provided)

into the pilot hole making sure it

passes through the shim and into the

rough opening framing.

Note: This step does not apply to

center latching double doors.

DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS

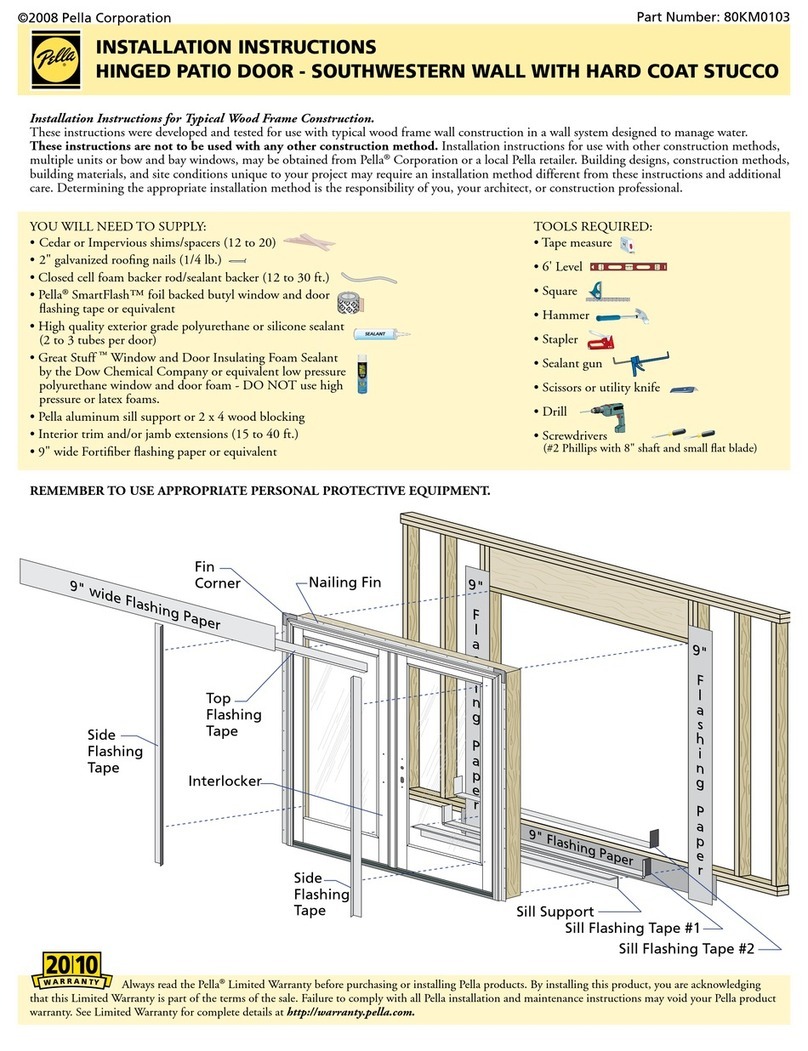

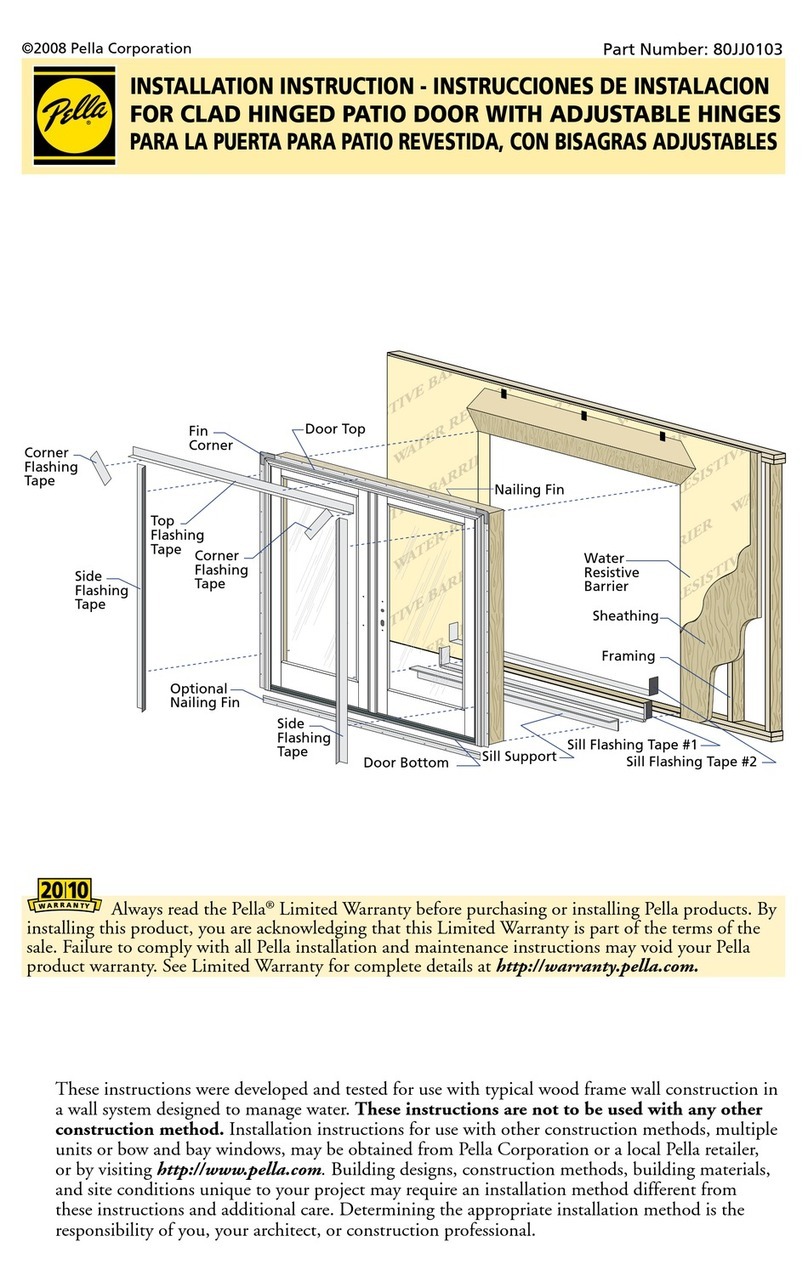

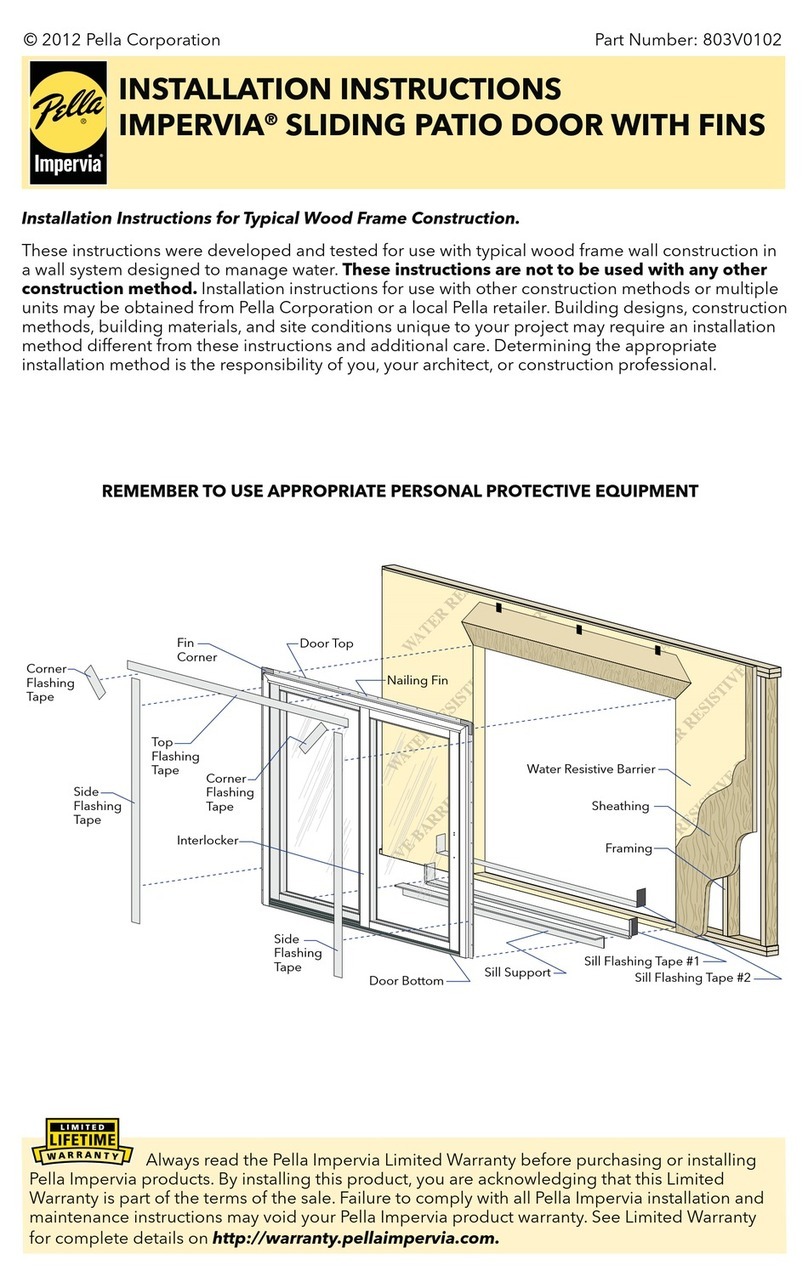

4INTEGRATING THE DOOR TO THE

WATER RESISTIVE BARRIER

A. Apply a corner bead of sealant at the point

where the brickmould or flat casing contacts

the wall along the head and jambs. Also apply

a bead of sealant at each end of the head

brickmould.

B. Install the head flashing.

C. Apply a piece of flashing tape

over the head flashing as shown.

&YUFSJPS

"

4A

#

)FBEnBTIJOH

4FBMBOU

4B

&YUFSJPS

%

4D

$

)FBEnBTIJOH

'MBTIJOHUBQF

4C

&

4E

D. Fold down the top flap of the

water resistive barrier. Cut

the water resistive barrier so it

covers the vertical leg of the

head flashing, however does not

lap onto the horizontal leg of the

head flashing.

E. Apply flashing tape to the

diagonal cuts. Cut two pieces of

flashing tape at least 1" longer

than the diagonal cuts in the

water resistive barrier. Apply the

tape covering the entire diagonal

cut in the water resistive barrier

at both upper corners of the

brickmould/flat casing.

3O

3O

3O

~8”

Head

*

A

M

B