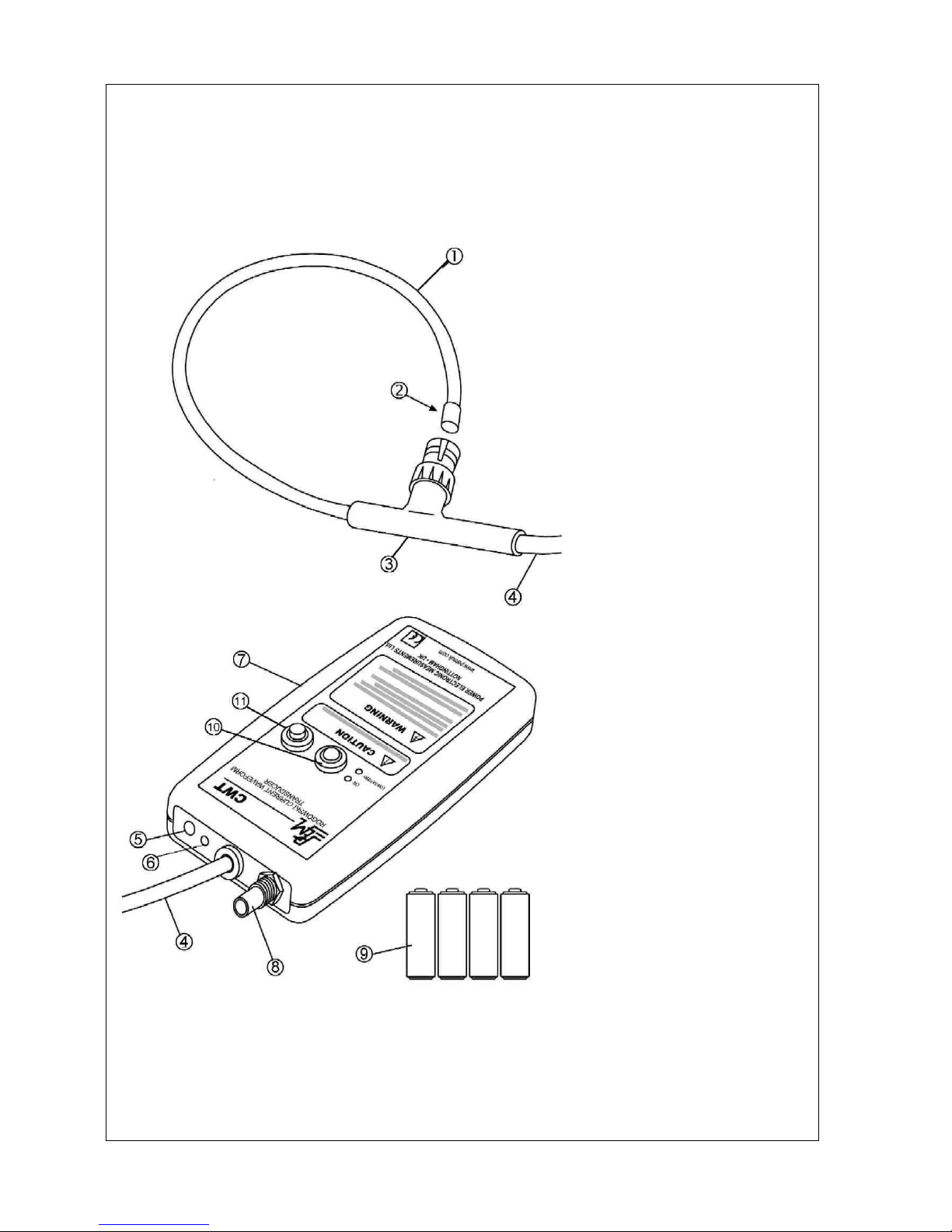

1. Connect the BNC plug on the output cable of the transducer to your oscilloscope or current

monitoring equipment. The CWT must only be used with oscilloscopes or monitoring equipment

which have their BNC INPUTS PROPERLY GROUNDED.

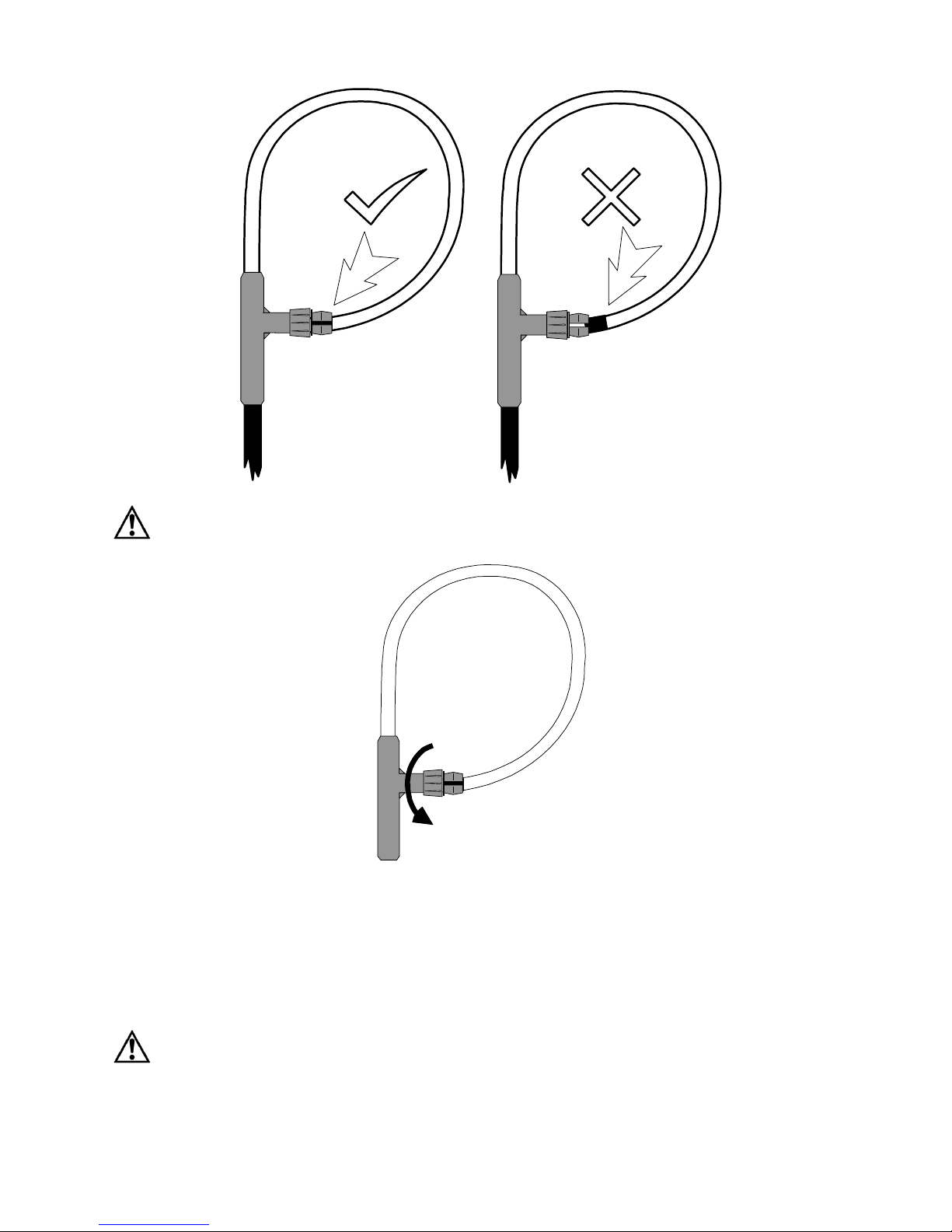

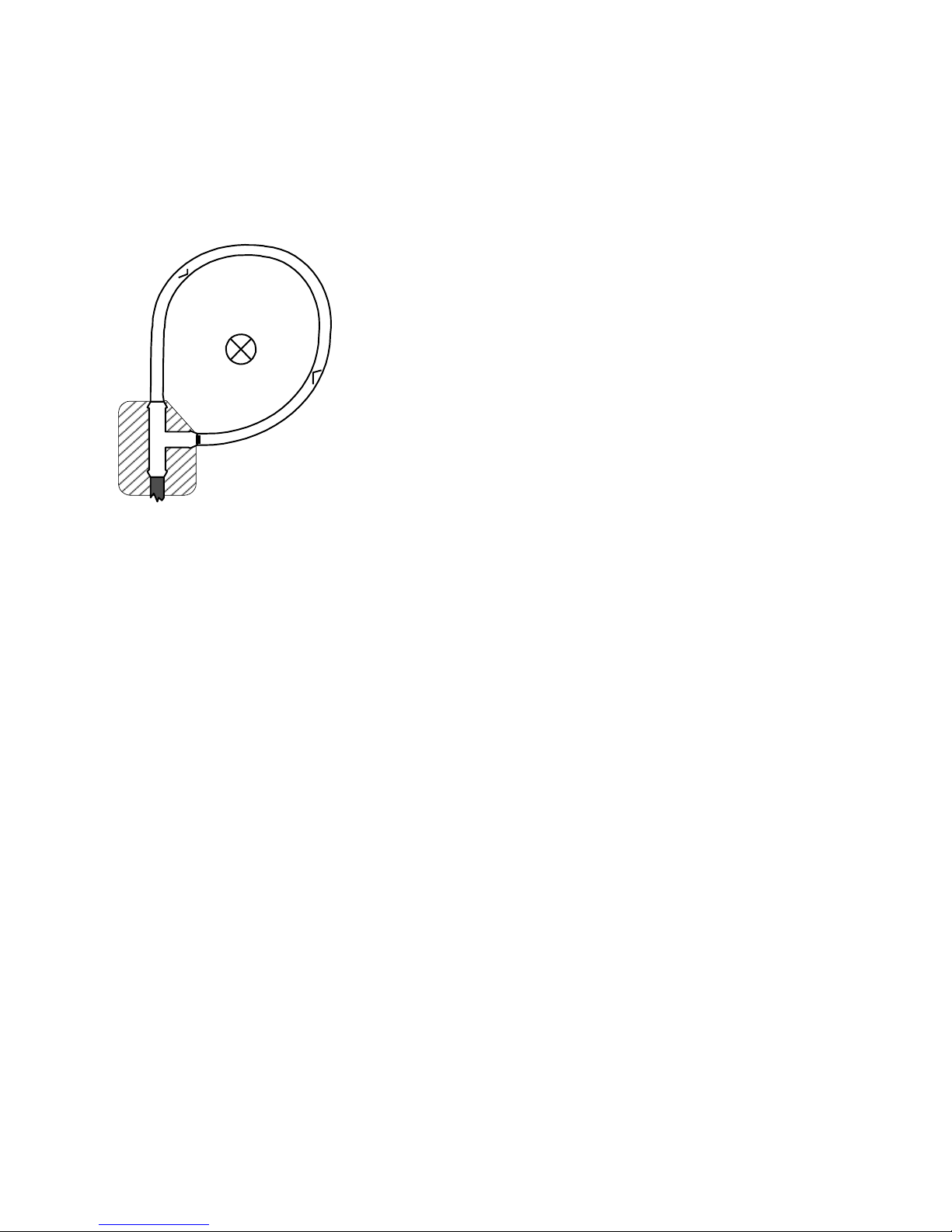

2. Having carried out the VISUAL INSPECTION of the Rogowski coil, un-clip the coil and wrap it

around the de-energised conductor under test.

3. Insert the free-end of the coil fully inside the ferrule and lock the jaws if necessary.

4. Re-energise the conductor.

5. The CWT is switched ON by pressing and releasing the ON push button, and is turned OFF by

depressing the button fully; the LED indicates that the CWT is ON when the LED is GREEN.

6. –EITHER - Standard alkali battery supplied CWT units - B

Four 1.5V AA alkali batteries provide about 70 hours operation. Battery voltage is continuously

monitored; healthy batteries are indicated by the GREEN LED. If the LED is RED the batteries are

delivering less than 2V and must be replaced by removing the sliding battery door in the back

cover of the integrator enclosure.

The units can also be powered by an external DC supply. The DC voltage can be between

12V(-10%) and 24V (+10%). When the DC supply is present a RED indicating LED adjacent to

the socket is illuminated. With the DC supply present the batteries are inoperative.

- OR - Re-chargeable battery CWT units - R

When fully charged four 1.2V AA NiMH rechargeable cells provide about 30hrs operation. Battery

voltage is continuously monitored; healthy batteries are indicated by the GREEN LED. If the LED

is RED the batteries are delivering less than 2V and must be recharged.

The units can also be powered by an external DC supply. The DC voltage can be between

12V(-10%) and 24V (+10%). When the DC supply is present a RED indicating LED adjacent to

the socket is illuminated. When the DC supply is present the batteries are inoperative and the

external DC voltage powers the integrator. In addition when the DC supply is present (regardless

of whether the integrator is on or off) the rechargeable batteries are trickle charged.

7. After switch-on the CWT requires a settling down time to attain its quiescent state before

providing correct current measurement. The time, which depends on warm-up and low frequency

bandwidth, can be as long as 2 minutes.