M-03-305 11/13/12

3

Level Sensing Controls: The float level controls

maintain the basin sewage water level by controlling

pump turn-on and turn-off levels.

1. The lower turn-off control should be set so that the

pump stops at approximately the top of the pump.

Consult the factory for any settings below this

point.

2. The upper turn-on control should be set above the

lower turn-off control. The exact height between

the two controls is determined by the number

of pump starts desired and depth of the basin.

A maximum of 10 starts per hour should not be

exceeded.

3. The override control is set at a specified height

above the upper turn-on control.

4. The alarm control is set about 6" to 12" above the

override control.

5. No control should be set above the inlet invert.

CAUTION: Never enter pump chamber after

sewage or effluent has been in basin. Sewage

water can give off methane, hydrogen sulfide

and other gases that are highly poisonous. Myers

recommends using the rail lift-out system so that

no service is required inside the basin.

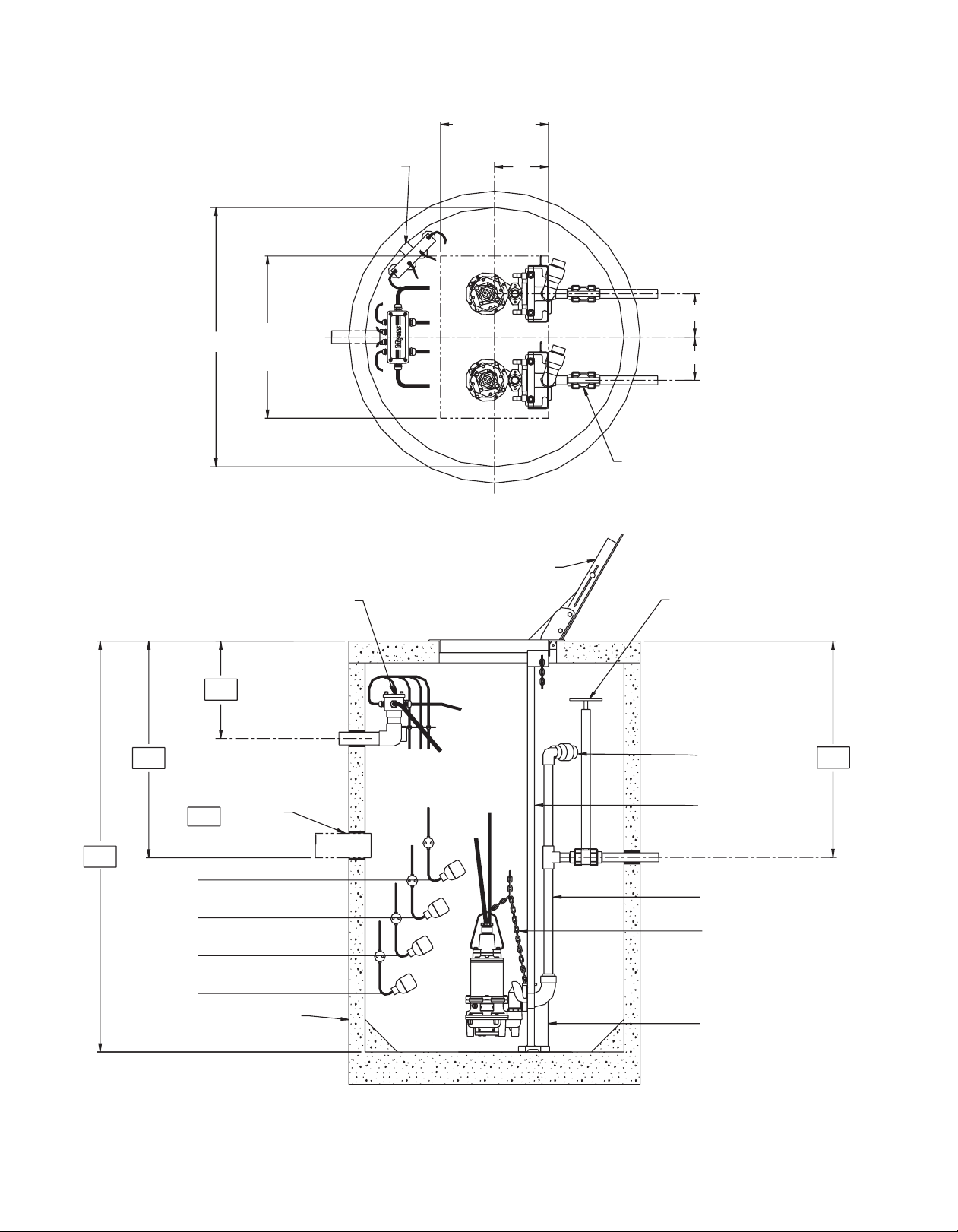

INSTALLING RAIL SYSTEM PARTS

Mounting Cover, Discharge Base and Rails

1. Set concrete cover with hatch opening in position.

2. Bolt top rail support plates to hatch frame. Two

1/4" bolts are required to attach each support.

3. Lower the base elbow into the basin.

4. Position the base elbow by dropping a plumb

line from center of pipe supports, located on

top rail support, to center of rail pins protruding

from the base elbow. Level the elbow flange in

two directions 90° to each other. Shims may be

required under the base in order to obtain this level

condition. Mark the position of the base hold-down

bolts through the holes in the base.

5. Move the base aside to allow drilling of the

concrete for 3/8" expansion bolts, 2" long. Move

the base over the bolt holes and recheck with level

and plumb line. Install expansion bolts.

6. Cut the pipe guide rails to the proper length and

install them between the pipe supports at the top

of the basin and the pins on the base. Guide rails

are to be Schedule 10 or Schedule 40, galvanized

or stainless steel.

7. Install discharge pipe as required by the particular

job specifications.

IMPORTANT: DISCHARGE PIPE AND GUIDE RAILS

MUST BE PARALLEL IF INTERMEDIATE GUIDE

BRACKET IS USED.

INSTALLING INTERMEDIATE

GUIDE BRACKET

(Required for each 20 feet of basin depth)

1. Remove guide rails and cut a piece from each

one. These pipes must be exactly the same length

and of a length that will permit installing the

intermediate guide bracket in the desired location.

2. Place the cut pieces of pipe over the guide rail pins

located in the base.

3. Set the intermediate guide bracket in position with

guides into pipe. Put U-bolt around discharge pipe

and tighten lightly.

4. Measure from joint on plug on intermediate guide

bracket to joint on plug on top rail support and

cut two rails to this length. Put rails in place and

tighten screws in top rail support.

5. Recheck rails; they must be straight and plumb.

Move intermediate guide bracket if necessary to

perfectly align rails. After alignment is secured,

tighten nuts on U-bolt.

6. If a second intermediate guide bracket is used, the

above procedure is followed for installation.

ATTACHING DISCONNECT TO PUMP

1. Bolt elbow onto pump volute at flange vise with

two 5/16-18UNC socket head cap screws.

2. Set lifting chain bail with one end on guide plate

eye bolt and other end on pump lifting eye.

INSTALLING PUMP AND DISCONNECT

1. Attach the lifting chain to the bail with clevis,

sliding the clevis along bail until the center of

gravity is found.

2. A hook is located on the top rail support to hold

the upper end of the chain when not in use.

3. Position pump so the guide rails are located in the

slots of the guide plate. Slowly lower the pump

down the guide rails to the base. The locating pins

(horizontal pins on sealing plate) should come to

seat in the inclined surface on the arms.

CAUTION: No persons should be in the sump basin

when pump is lowered into position!

Air Venting: Air tends to trap in the pump volute when

water rises in the sump or when the pump is lowered

into water after service. To vent off this air, a small

hole is drilled into the pump volute. Be sure this vent

hole is clean after any service work on pump.