ii

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

Important Notice:

Attention Installer: This guide contains important information

about the installation, operation and safe use of this product.

This information should be given to the owner and/or operator of

this equipment after installation of the pool cleaner.

Attention User: This manual contains important information

that will help you in operating and maintaining this pool cleaner.

Please retain it for future reference. Consult Pentair with any

questions regarding this equipment.

Before installing this product, read and

follow all warning notices and instructions which are included.

Failure to follow safety warnings and instructions can result

in severe injury, death, or property damage. Call 1300 137 344

for additional free copies of these instructions.

Consumer Information and Safety

This pool cleaner is designed and manufactured to provide

many years of safe and reliable service when installed,

operated and maintained according to the information in this

manual. Throughout the manual, safety warnings and cautions

are identied by the

“ ” symbol. Be sure to read and comply

with all of the warnings and cautions.

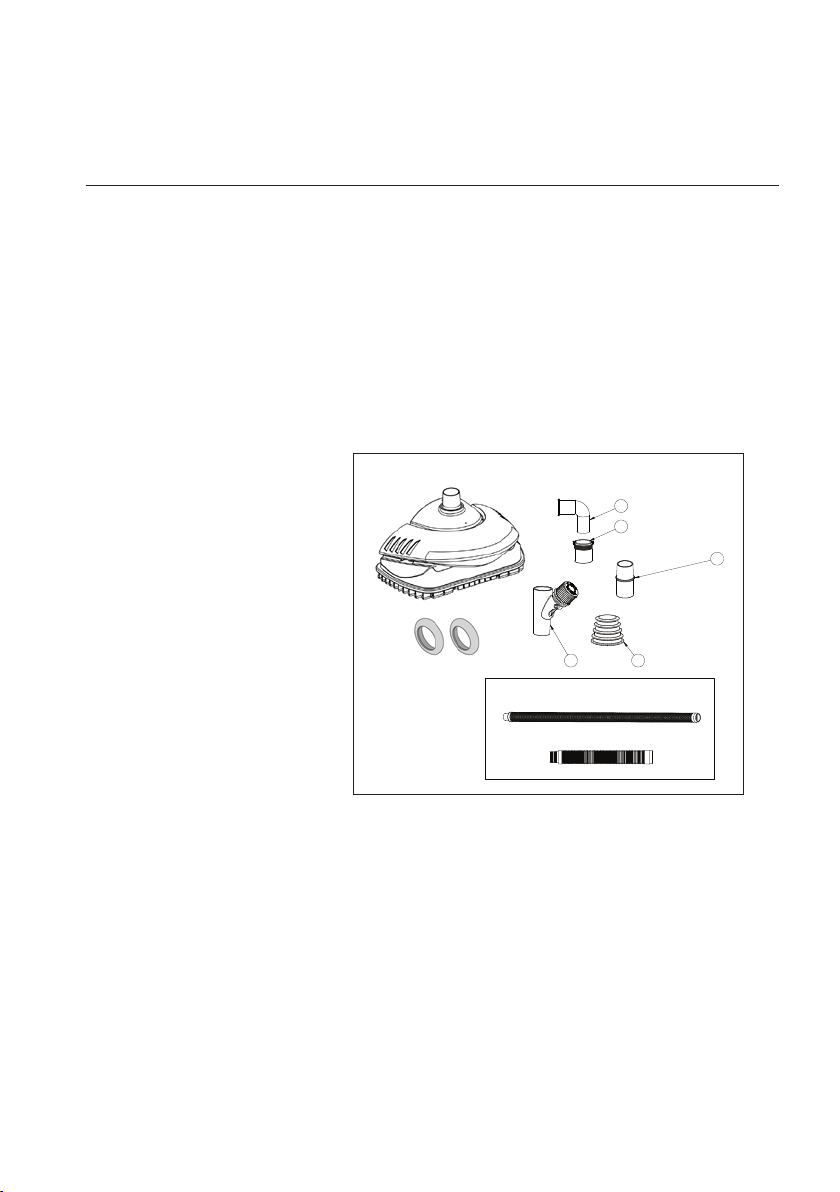

General Installation Information

Pre-Installation Check List

Before installing your cleaner, review and understand all

warnings and safety information in this guide. Failure to

follow these instructions or improper installation of the

cleaner can result in damage to the pool nish or the vinyl liner,

Pentair Water Pool and Spa, Inc. disclaims any liability for

repairs or replacement to any of these structures or

components of the customer’s pool.

Before installing the cleaner in a vinyl liner pool:

Check liner closely for signs of deterioration or damage

from age, chemicals, pool wall damage, etc. If any damage is

found, have a qualied pool professional make all the necessary

repairs. Also, if there are stones, roots, etc., under the liner,

remove them before installing the cleaner.

Before installing the cleaner in a gunite pool or a pool that is

partially or completely tiled:

Repair loose tiles and tighten any loose light rings.

Before installing the cleaner, clean your lter system:

Make sure you have cleaned the lter, including backwashing,

rinsing, and emptying all baskets. A clean system is necessary

for proper cleaner operation and coverage.

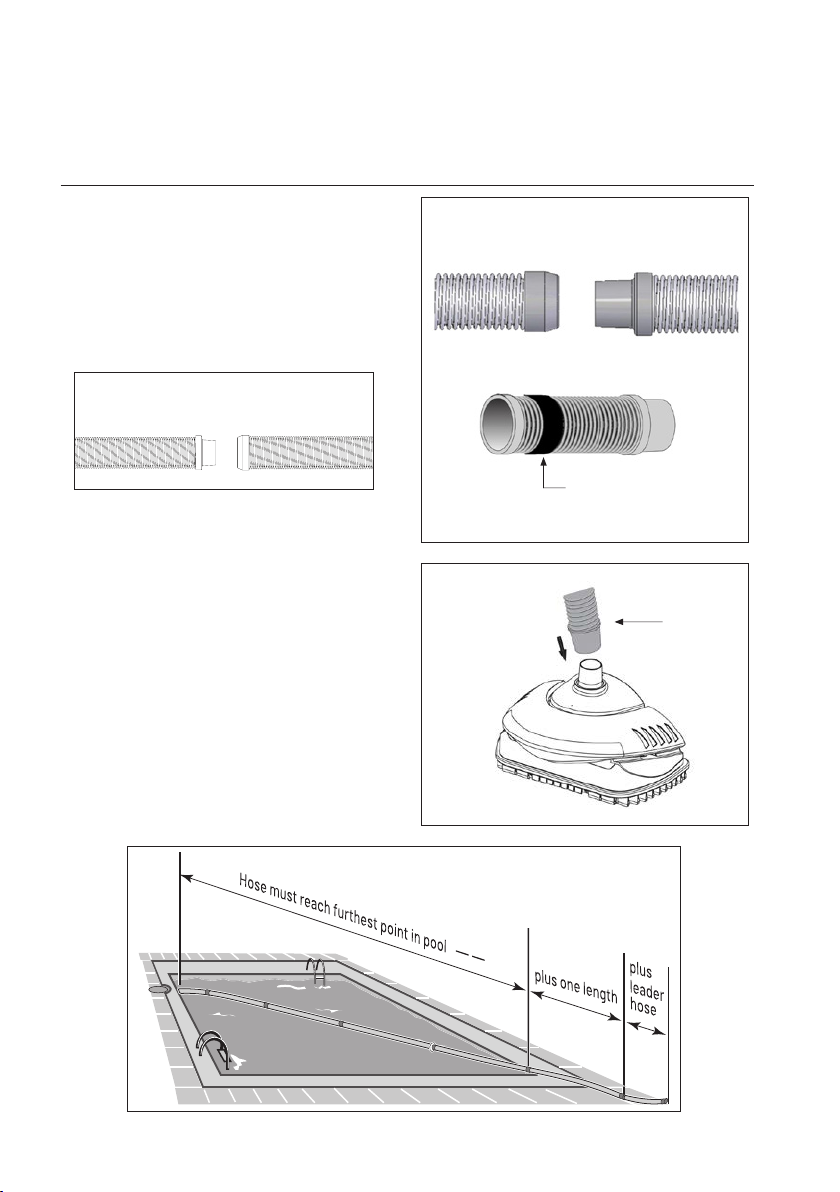

Before installing the cleaner, understand cleaner coverage:

The cleaner is designed to rid your pool of debris in

approximately 4-6 hours. Less time could be needed,

depending on the pool size. The cleaner was not designed to

automatically clean steps or swimouts or to work under a solar

cover. It was also not designed to do initial cleanup for a new

pool or when opening your pool for the season.

AFTER installing the cleaner, make sure the cleaner is

operating correctly:

The cleaner may need some minor adjustments to make

sure it is operating properly so there is no damage to the

pool nish. Certain vinyl liner patterns are particularly

susceptible to surface wear, pattern removal, ink rubbing off

of, or serious scratches to the pattern caused by objects

coming into contact with the vinyl surface, including

automatic pool cleaners. Pentair Water Pool and Spa, Inc. is

not responsible for any pattern removal, abrasions or markings

on vinyl liners.

HAZARDOUS SUCTION.

Do not play with cleaner or hose or apply to

body. Can trap and tear hair or body parts.

Hose can trip or entangle swimmers which

could result in drowning.

SUCTION ENTRAPMENT, INJURY, AND

DROWNING HAZARD. If your pool has a

dedicated suction port (“vac port”) for

vacuuming or for an automatic pool cleaner,

it must be covered when not in use. A spring

loaded safety cover (a “vac port tting”) is

included with your cleaner. Install it on the

suction port to prevent entrapment and injury.

If the cover provided does not t, purchase one

that does from your local pool store and install

it instead. The cover should conform to IAPMO

SPS4-99A.

Stop pump before attempting to clean

unit. Do not allow swimmers in pool while

pool cleaner is operating.

To reduce the risk of injury, do not let

children use or play with pool cleaner.

Do not allow swimmers in the pool while pool

cleaner is operating. Hose can trip or entangle

swimmers which could result in drowning.

Moving parts may injure hands or ngers.

Stop pump before attempting to clean out

pool cleaner head.

Warnings and safety instructions for Pentair Water Pool and Spa,

Inc. pumps and other related products are available at:

http://www.pentairpool.com/pool-owner/safety-warnings/or call

(800) 831-7133 for additional free copies of these instructions.

Please refer tohttp://www.pentairpool.com/pool-owner/

safetywarnings/for warning and safety instructions related to

this product.