NOTE: This recorder uses "A" rtround tape, i. e. the

dull magnetic coated side faces the center of

the reel. If the tape used is type ',B!' (coated

side facing outward) recordings will be made

at a very low sound level and playback will be

inaudible.

2. Place an empty reel on the left hand spindle

(take-up reel). Be sure that both reels are engaged

with the 3 fins on each spindle.

3. Reel out about 16t! of tape and hold a section

straight with both hands. Drop tape into tape slot.

Thread the end of the tape into one of the slots in the

outer surface of the take-up reel hub. Rotate take-up

reel several turns to secure tape to reel and to take

up slack between reels.

To Record From Microphone-

1. Insert the microphone plug into the "Mic. I'

jack.

2. Turn the "Volume-On-Off" control to the "On"

position. This supplies power to the amplifier.

3. Turn the "Tone-On-Off" control to the "On"

position. This supplies power to the motor.

4. Beforemakinga recording it is generally ad-

visable to set the volume at the proper ievel. To do

this, hold the record lock button (26) down and while

talking into the microphone in a natural tone, adjust

the "Volume" control so that the peaks of the meter

deflection do not go past zero, or into the red area of

dial calibration.

5. While hoiding record lock button (26) in the

down position, move the "Unimagic!' control (5) to the

Playposition. A recording is now being made and any

sounds entering the microphone will be recorded on

the tape.

To Record From Radio, TV, Or Phonograph-

1. Using a standard interconnecting cable such

as the Pentron accessory cord X-166, fasten the two

clips to the loud speaker terminaLs of the externai

source, and insert the plug on the other end into the

"Radio'input on the recorder.

To Monitor A Recording-

By plugging a set of earphones in the "Ampl. I'

jack the recording maybe monitored. Inanemergency

the microphone will serve as an earphone if plugged

into this same jack. Continued use of the microphone

in this fashion is not recommended since permanent

damage may result,

To Play A Recording-

1. Move the Unimagic control (5) to the t'Playil

position.

2. Adjust "Volume" and "Tone"controls for de-

sired listening level.

Dual Track.Es gellling-

This recorder is designed so that only one-half

the tape width is recorded at a time, therebyresulting

in dual-track recording. To make dual-track record-

ing proceed as follows:

l. After a reel of tape has been recorded, i. e.

all the tape wound onto the take-up reel, place the

"Unimagic" control (5) in neutral (upright) position.

2. Remove the reels from the recorder, turn

thefullreelover and place it on the right-hand spindle

and place the empty reel on the left-hand spindle.

3. Thread the tape and proceed with the re-

cording.

4. After the second track has been recorded the

first track is ready to be played, without rewinding,

as follows:

(a) Place the full reel on the right-hand spindle

and the empty reel on the left-hand spindle.

(b) Thread the tape and set the controls as

described under "To Play A Recording".

FUNCTIONS OF PRINCIPAL PARTS

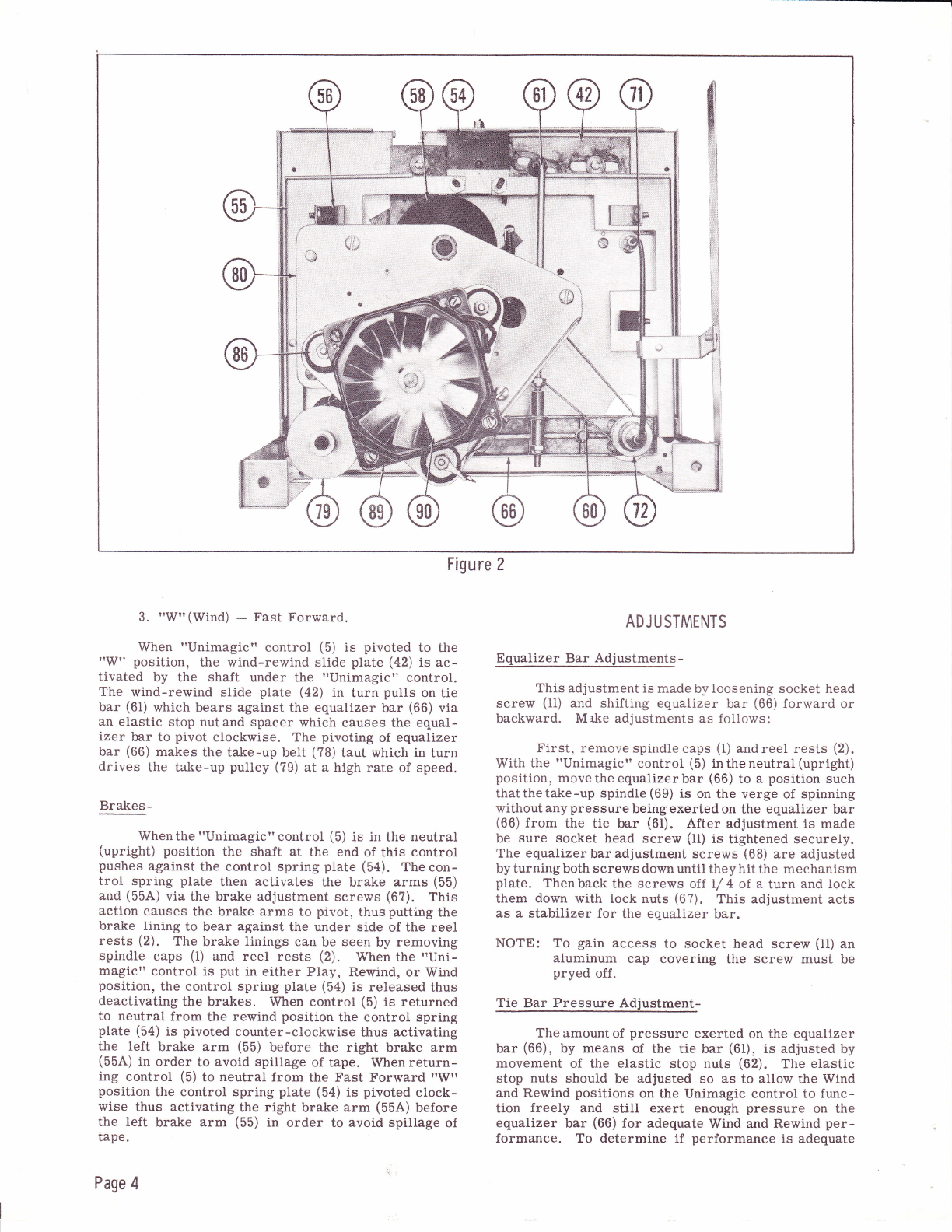

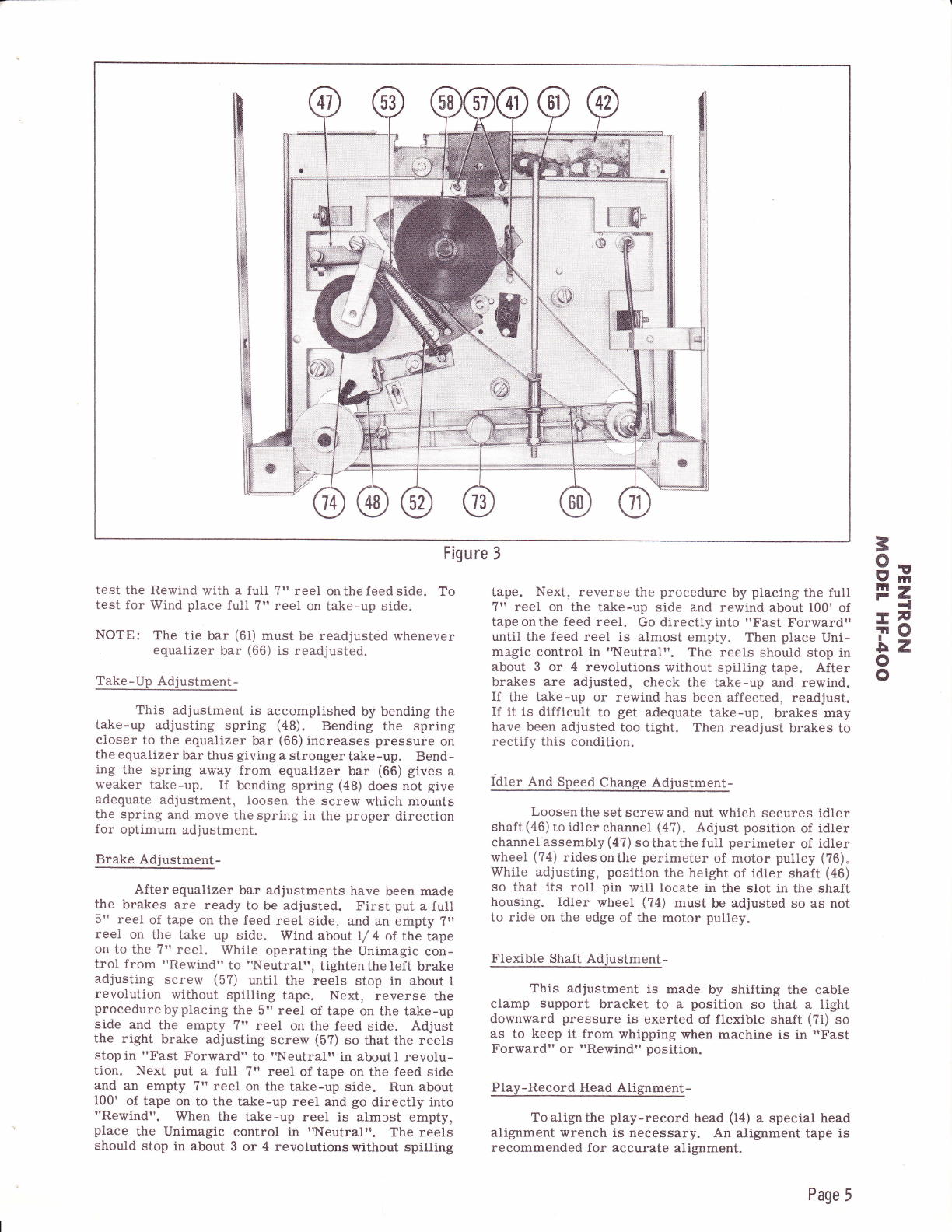

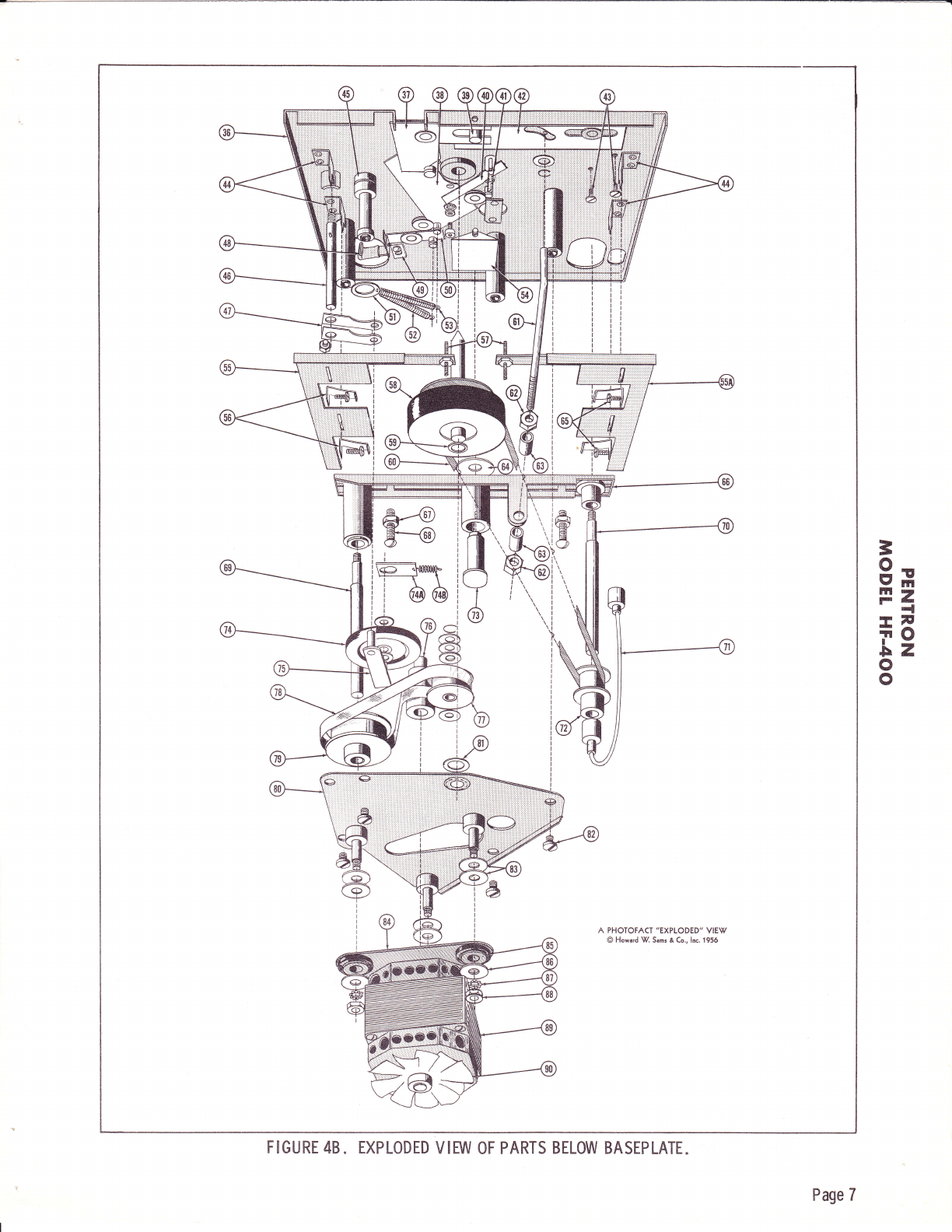

Unimagic Control (5)-

This control has three positions:

1, rrP-R'r - Play And Record Position.

When the "Unimagic" control (5) is moved into

the trP-Rtr position. the piay-record control cam (3?)

is actuated by the shaft in the control. This pivoting

movementof cam (3?) allows the pressure roller slide

plate (38)tobe activated by the pressure roller spring

(53) which engages the pressure roller (24) with the

capstan (58) which in turn drives the tape at a constant

speed. The take-up adjusting lever (50) which is held

againsttheendof slide plate (38) by the take-up spring

(52) , is pivoted as the slide plate moves forward. This

causes the boot on take-up adjusting spring (aB) to

press against the equalizer bar (66) with just enough

pressure for the take-up belt (78) to become taut and

to rotate the take-up pulley (79) so as to wind tape on

the reel. This acts as a ciutch by allowing the belt to

slip due to the slower speed of the capstan. Also, by

the movement of slide plate (38) , pressure is removed

from the pressure finger lever (40), whichhasbeen

engaged with the pressure pad pivot pin on the pres-

sure pad carrier (32). which holds the pressure pads

away from the heads. When pressure is removed

from the pressure finger lever (40) the pressure pad

spring (41) pulls the pressure pad carrier (32) inward

causing pressure pads (22) to bear against the tape

and hold it in positive contact with the heads.

NOTE: Mechanical functions explained above pertain

to both Play and Record.

2. I'Rr' -- Rewind.

When the "Unimagict' control (5) is pivoted to

the "R" position the wind-rewind slide plate (42) is

activated by the sha-ft under the "Unimagic" control.

The wind-rewind slide plate (42) in turn pushes on the

tie bar (61) which bears against the equalizer bar (66)

via an elastic stop nut and spacer which causes the

equalizer bar (66) to pivot counter-clockwise. The

pivoting of the equalizer bar makes the feed belt (60)

taut which in turn drives the feed pulley (?2) at a high

rate of speed.

3

9*

Pz

-l

-il,

io

Lz

o

o

Page 3