10 Page Operation and maintenance manual for the KSM series boilers with feeders. The producer reserves the right to introduce technical modifications.

2.5. Fuel

Fuel used for combustion in the KSM boiler should have suf-

cient caloric value > 28 MJ/kg, be dry (moisture content

< 11%), have a size recommended by the producer 5-25 mm,

have correct ash content (maximum 2-7%) and have > 15%

of the volatile content. Use of moist or too large fuel can lead to

locking in the feeder and serious failure of the boiler.The unfa-

vourable chemical composition of the fuel can result in sintering

and formation of large amounts of dust and soot and increased

fuel consumption. Boiler burn time depends on many factors:

the caloric value of fuel, thermal insulation building, equip-

ment receiving the heat (heaters, boiler, oor heating). Burn

time period is longer by several hours during boiler operation

with lower thermal power..

PRIMARY FUEL

its use ensures that the boiler will achieve the declared heating power and eciency

KSM hard coal (eco-pea coal, class 28/50/06 with grain size 5-25 mm)

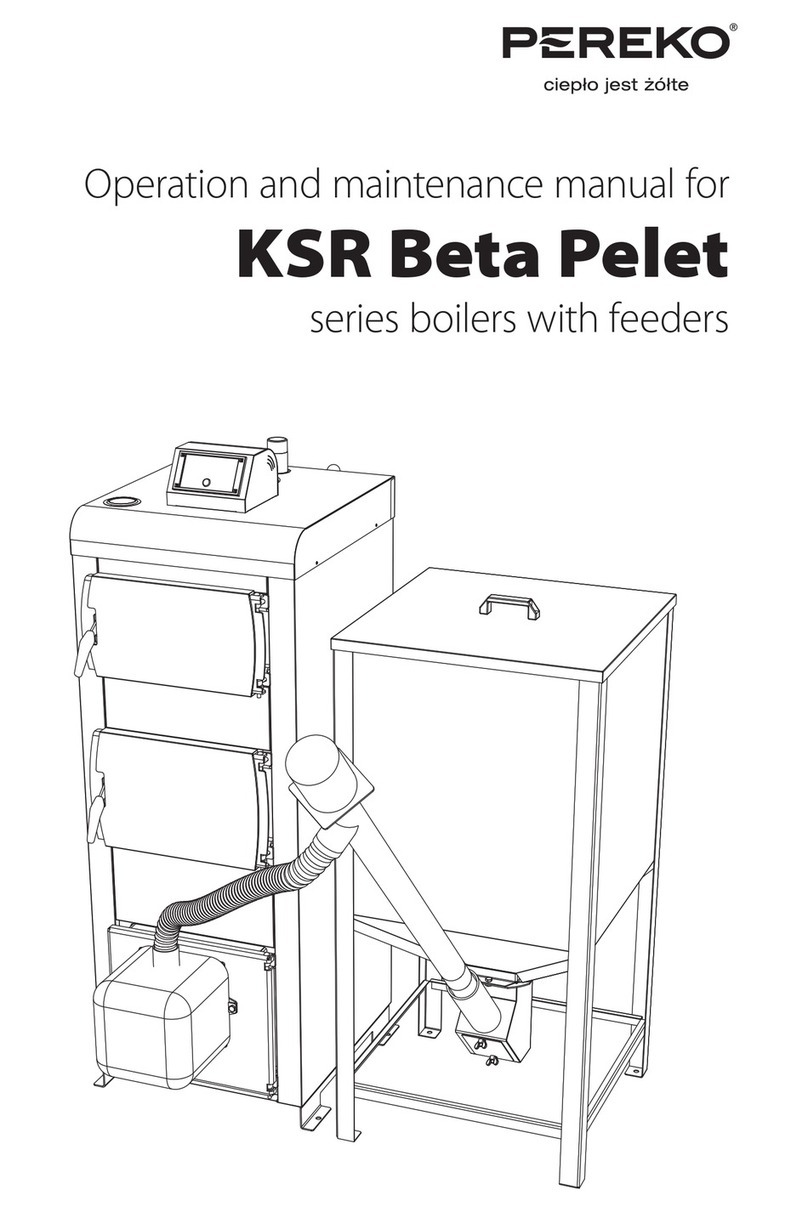

2.6. Equipment

Prior to the boiler setting you should check the presence of addi-

tional tools and operation of the instrumentation.The complete

set should include: automatic feeder,

fuel container, electronic controller, fan, brush, hook, ash shovel,

drain cock, fuel swirlers (one piece for each smoke tube).

3. BEFORE START-UP

3.1. Boiler room

• It should be a separate room with height not lower than

2.2 m in the newly constructed building (in the already ex-

isting buildings the allowable height equals to 1.9 m).

• It should have articial lighting installed and have natural

lighting as far as practicable.

• It should have gravity ventilation in good working order,

including:

1. air-supply duct in the external wall with cross-section

not lower than 50% of chimney cross-sectional area on

height maximum 1 m over the ooring or not lower than

200 cm2for boilers with power up to 25 kW or 400 cm2

for boilers over 25 kW,

2. separate air-exhaust duct on the internal wall with

cross-section not lower than 140×140 mm with an out-

let located under the boiler-room roof near the chimney.

NOTE! It is forbidden to use mechanical exhaust ventilation

in the room where the boiler was installe.

• Floor gully and oor with 1% slope towards the outlet

should be planned in the central part of the room.

• Flooring and walls in the whole room should be made of

non-combustible materials.

• The doors to the boiler room should open outwards.