INTRODUCTION

This owner’s manual is provided to ease assembly,

maintenance and use of your Prindle Catamaran. We

believe these instructions portray the simplest methods.

Do it our way the first time and learn from us. Then, if

you discover a better method, feel free to tell us about

it by faxing (714) 541-6643 or e-mailing pcat@perfor-

mancecat.com. You may see your idea appear in the

next edition of the owner’s manual.

We are sure you will enjoy your Prindle Catamaran and

hope that this manual will make your enjoyment easier

to come by.

Make sure you join the Prindle Class Association - it’s fun

and it’s free to any new owner of a Prindle Catamaran

($20 annually after the first year). You will receive the

Performance Sailor, our official class newsletter. This

newsletter contains feature articles, news and results of

regattas, photographs, timely tuning tips, special

announcements and contests. As a member of the

Prindle Class Association, you will also be entitled to

enter and participate in all of our Class sanctioned regat-

tas.

One design racing begins at the local fleet level leading

to regional qualifying regattas and culminates with the

Annual National Championship Regattas held in a differ-

ent region every year. Even if you are not a racer, join

the Prindle Fleet in your area. Our fleets have held such

fun events as watermelon hunts, hull flying contests,

group cruises, Prindle barge picnics and clinics. It’s

much more fun to share the joy of sailing a Prindle

Catamaran. If a fleet does not exist in your area - start

one! All you need is a few enthusiastic owners!

Make sure your dealer fills out and submits your war-

ranty card for your new boat. Not only does it validate

your warranty, but it will also automatically register you

as a member of the Prindle Class Association. If you

have purchased a used Prindle, please send us your sail

and hull numbers as well as your complete address.

Make sure to notify us when you move too, the

Performance Sailor does not get forwarded.

Keep in touch. We love to hear from our owners!

1800 East Borchard Avenue

Santa Ana, CA 92705

(714) 835-6416

(714) 541-6643 fax

www.performancecat.com

CONTENTS

SECTION I: ASSEMBLY

Preparation 3

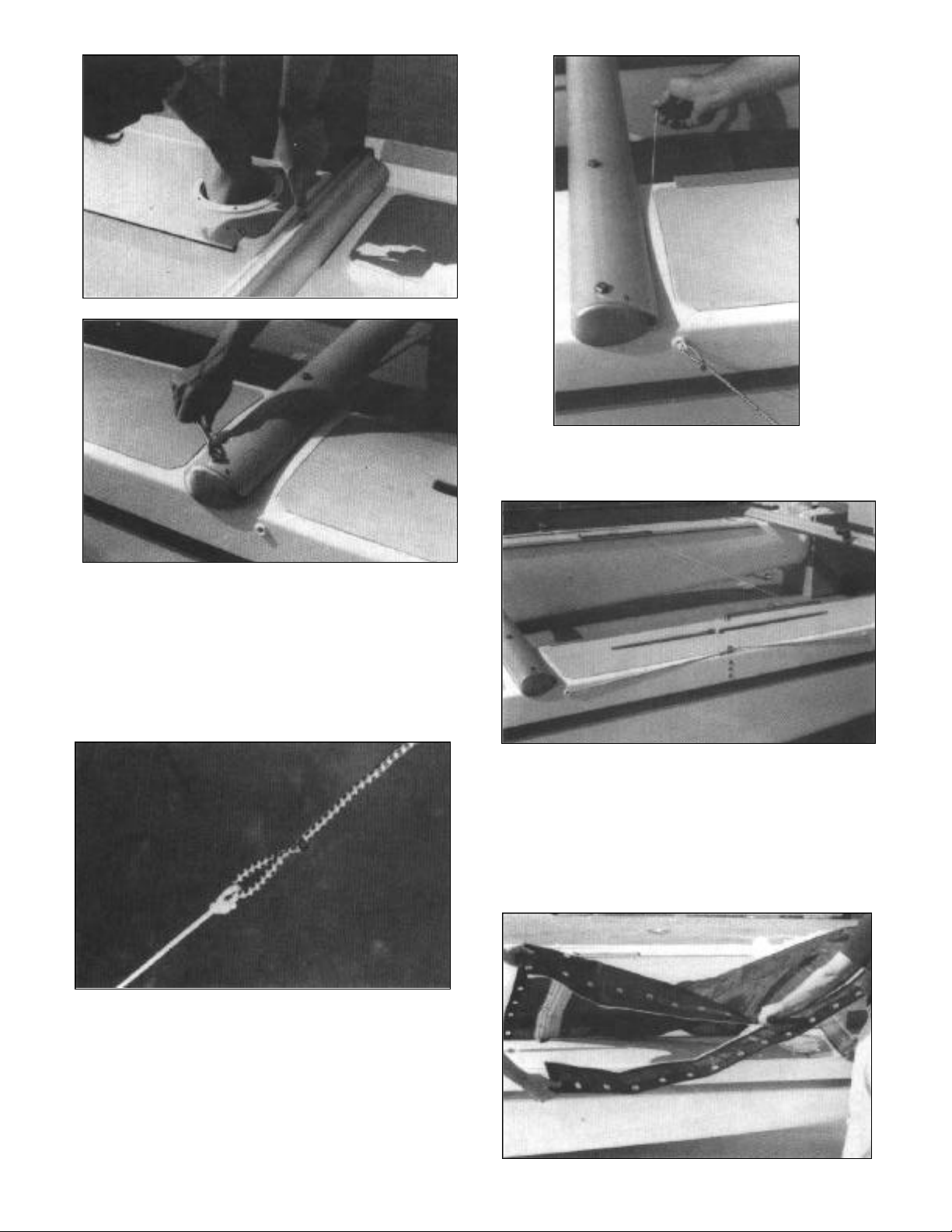

Crossbars 3

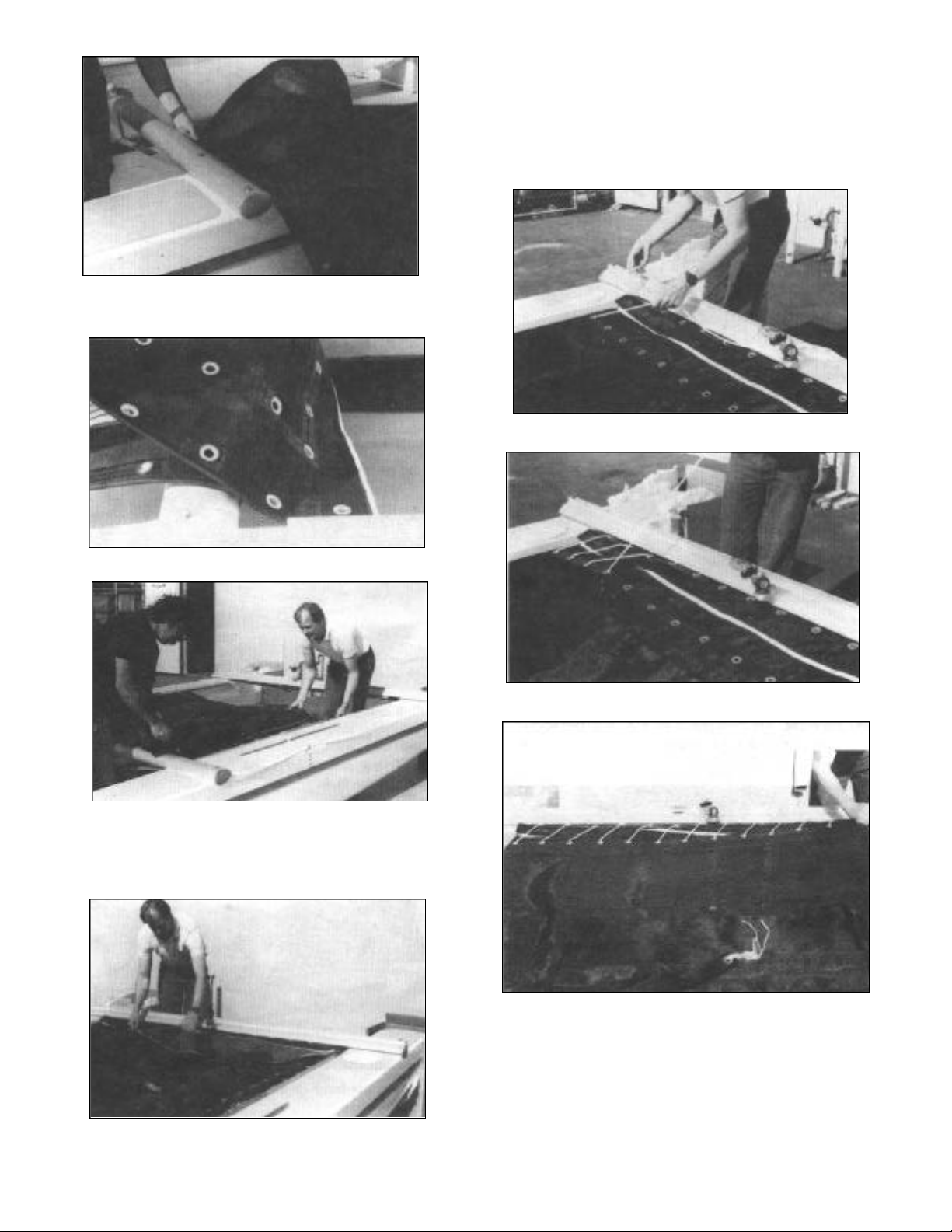

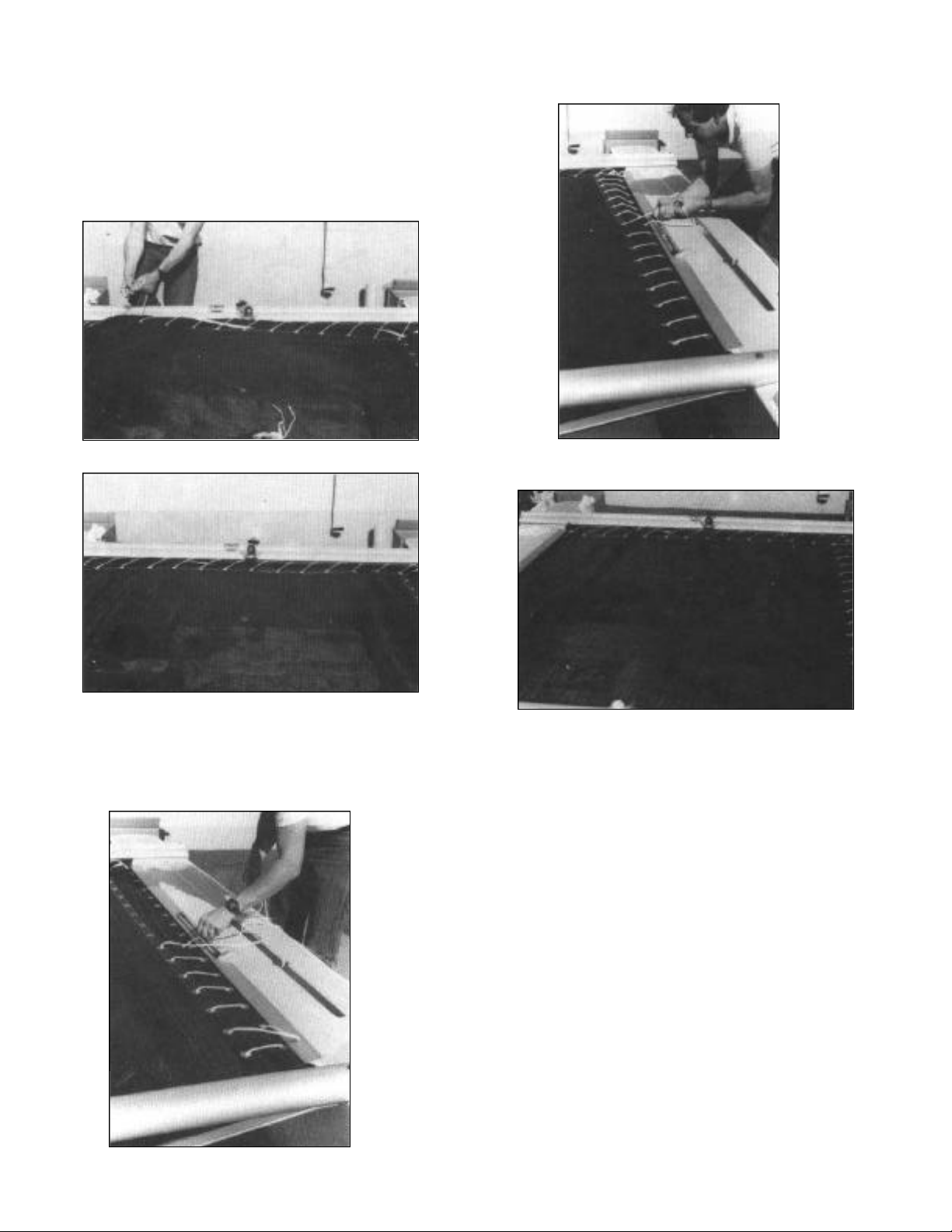

Trampoline 5

Standard Jib System 8

Deluxe 4-Way Jib System 8

Jib Sheet 10

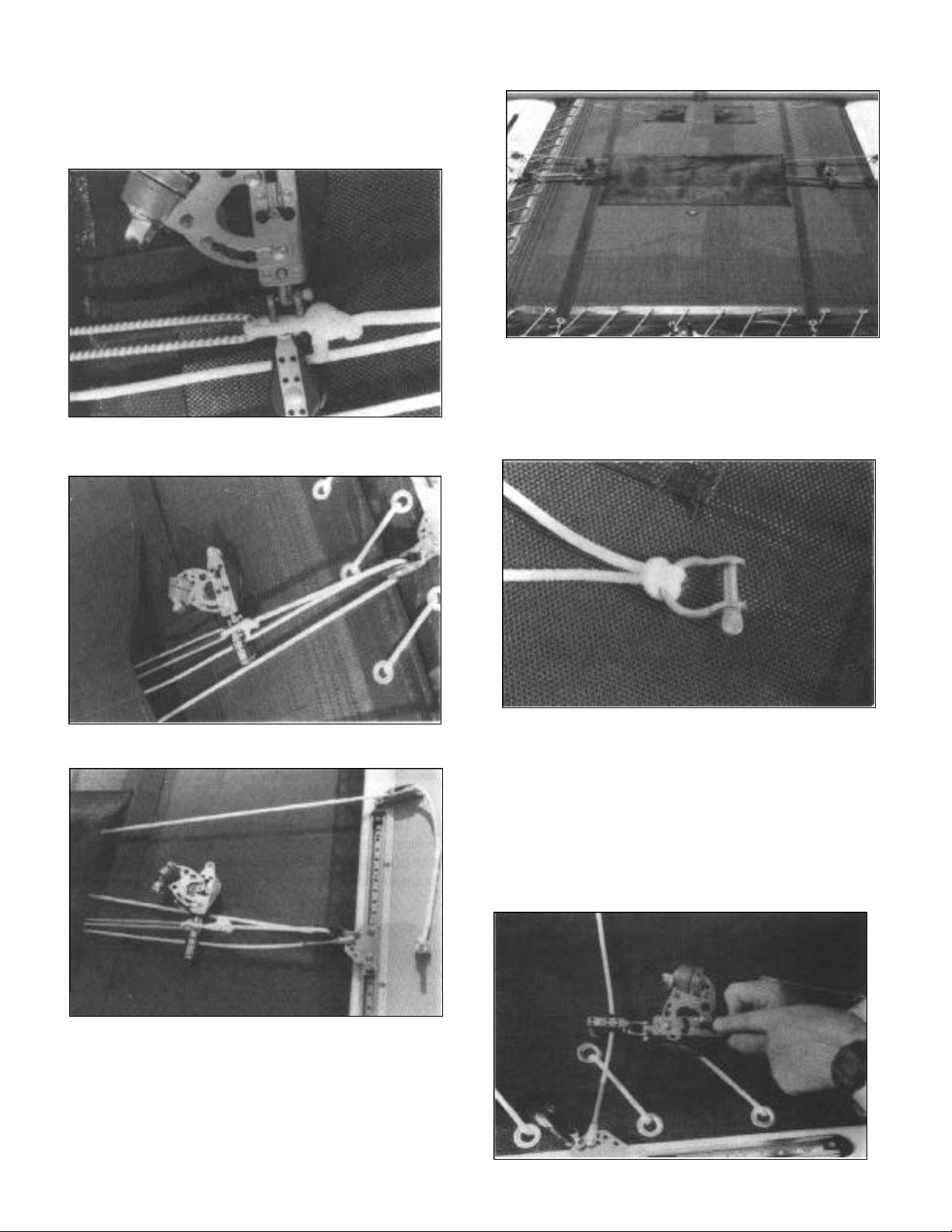

Rudder System 11

Castings 11

Tiller Crossbar 11

Tiller Extension 11

Rudder Blades 12

Rudder Lock Bolt 12

Adjusting the Helm 12

Rudder Alignment 13

Operation of Rudder System 13

Mast and Rigging 14

Spreaders 14

Diamond Wires 15

Mast Rotator 16

Masthorn 16

Shrouds and Trapeze Wires 17

Forestay and Jib Halyard 17

Main Halyard 17

Raising the Mast 18

Diamond Wires 20

Sails and Battens 21

Mainsail Battens 21

Hoisting the Mainsail 22

Boom 23

Mast Rotator 23

Downhaul 23

Mainsheet and Traveler 24

Jib 24

Jib Sheet Jam Preventer 26

Righting Line 26

Tightening rig tension 26

Centerboard 27

SECTION II: SAILING

Sail Trim

To Weather 27

Reaching 28

Downwind 28

Downhaul Systems 28

Trapezing

Lacing the Harness 28

Trapeze Positioning 29

Launching

Onshore 30

Offshore 30

Tacking 31

Jibing 32

Balance 33

Righting 33

SECTION III: AFTER SAILING

Loosening the rig 36

Lowering the sails 36

Trailering 38

SECTION IV: MAINTENANCE

Dolphin Striker 40

Battens 41

Foam/Fiberglass Battens 41

General Maintenance Tips 41

Hulls 41

Rudders 41

Sails 42

Outhaul Systems 42

SECTION V: TUNING PERFORMANCE

Mast Rake 43

Mast Rotation 43

Barberhauler 43

SECTION VI: SUPPLEMENTAL INFORMATION

Major Parts of a Boat 44

Glossary of Terms 45

Knot Illustrations 46