2

Contents

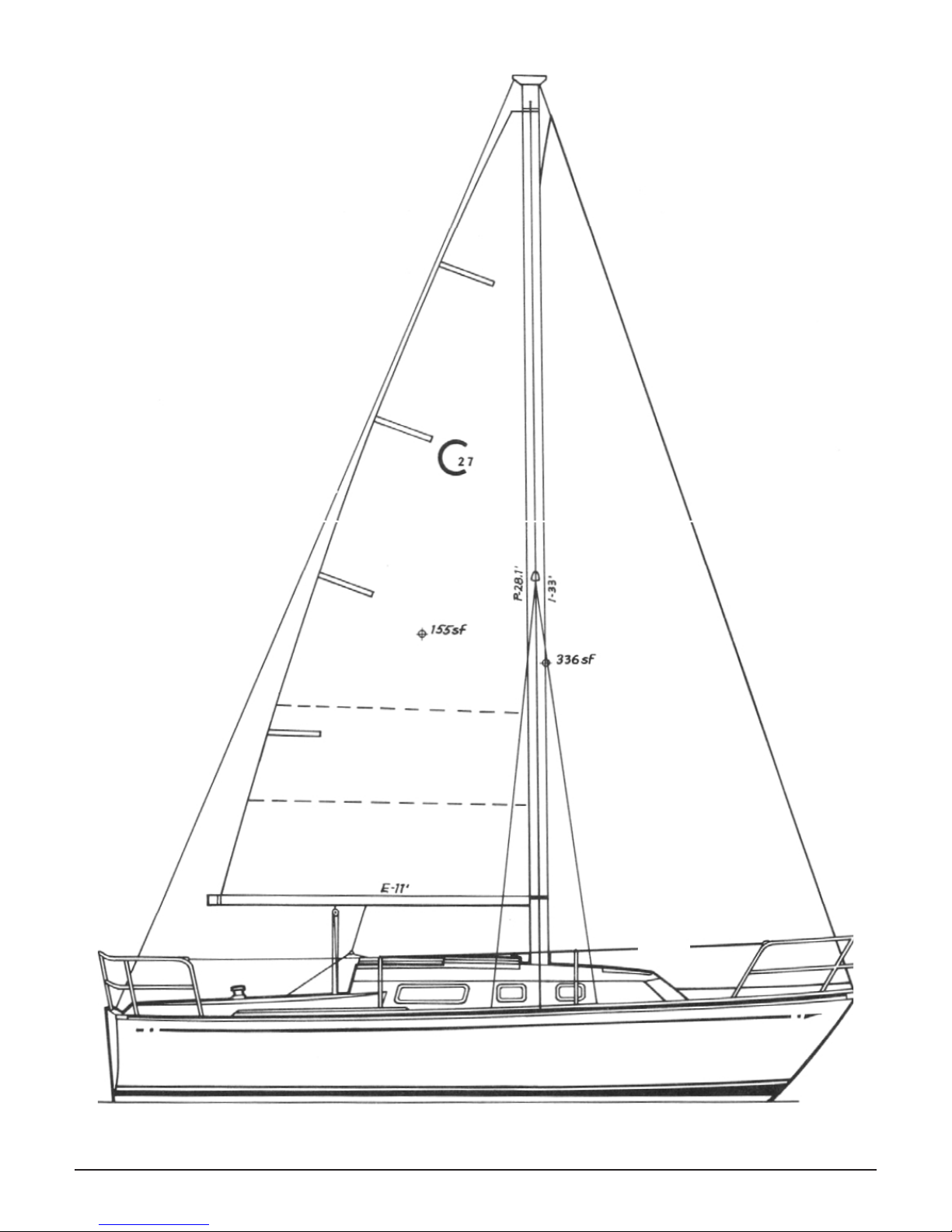

CAL 27 Mk III BOAT DIMENSIONS ............................................................4

COMMISSIONING ...............................................................................8

PRE-LAUNCH CHECK LIST........................................................................8

COMMISSIONING NOTES .....................................................................10

Note No.1.......................................................................................10

Note No.2.......................................................................................10

STEPPING AND TUNING THE MAST .........................................................11

RIGGING DIMENSIONS ........................................................................12

CAL 27 RUNNING RIGGING ...................................................................12

Wire Rigging....................................................................................13

BOAT STORAGE ................................................................................14

ENGINE OPERATING INSTRUCTIONS........................................................15

Alignment of Engine to Shaft ..................................................................15

Stung Box ....................................................................................16

FLOODING OF ENGINE WITH WATER............................................................16

Operator Error..................................................................................17

FUELING PROCEDURE.........................................................................19

ELECTRICAL.....................................................................................20

Master AC and DC Control Panels ..............................................................20

Circuit Breakers ................................................................................20

Battery Selector Switch ........................................................................20

CAUTION!.......................................................................................20

SHORE-POWER SYSTEM ......................................................................21

LIGHTNING GROUND..........................................................................23

NAVIGATION LIGHTS ..........................................................................24

We recommend: ................................................................................24

WATER SYSTEM ................................................................................25