IMPORTANT SAFETY INFORMATION

while tired or under the inuence of drugs, alcohol, or

medication. A moment of inattention while operating this

product may result in serious personal injury. Keep proper

footing and balance at all times. Do not reach over or

across running machines, hoses, cords, etc.

6.

Dress properly. Do not wear loose clothing or jewelry. Keep

your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in moving parts.

7.

Inspect before every use; do not use if parts are loose

or damaged.

8. Do not alter this product in any way.

9. Use the right tool for the job. Do not attempt to force a small

tool or attachment to do the work of a larger industrial tool.

Don’t use a tool whose performance is not adequate for

your work. Do not modify this tool and do not use this tool

for a purpose for which it was not intended.

10. Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

11. Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is

earthed or grounded.

12.

Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

13. Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

14. When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

15. If operating a power tool in a damp location is unavoid-

able, use a ground fault circuit interrupter (GFCI)

protected supply. Use of a GFCI reduces the risk of

electric shock.

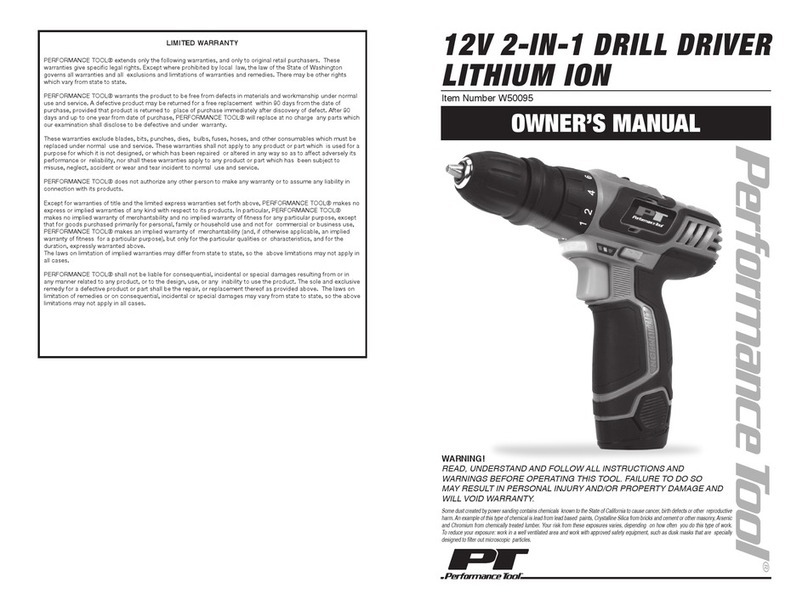

16. Before using battery pack, please read carefully all

instructions and cautionary markings on battery pack,

battery charger and product using battery. Do not inciner-

ate the battery pack even if it is severely damaged or is

completely worn out. The battery pack can explode.

17. Do not carry battery packs in aprons, pockets, or tool

boxes, product kit boxes, drawers, etc. with loose metal

objects. Battery pack terminals could be short-circuited

causing damage to the battery pack, severe burns or re.

18. The battery pack is Nickel-Cadmium (Ni-Cad) and is

considered to be a toxic material by the Environmental

Protection Agency. Before disposing of damaged or worn

out Ni-Cad battery packs, check with your State Envi-

ronmental Protection Agency to nd out about special

restrictions on the disposal of these battery packs.

19. The battery is not fully charged. Before rst use, the

battery pack requires 8-10 hours charge time to be fully

charged. Subsequent recharging needs 3-5 hours for the

battery to be fully charged.

20. Always switch to a fresh battery when tool performance

begins to diminish. Severe heat is most destructive to a

battery; the more heat generated, the faster the battery

loses power. A battery that gets too hot can have a

shortened life.

21.

Never over-discharge a battery by using the tool even

after tool performance has decreased. Do not attempt to

discharge a tool’s battery by continuing to pull on the tool

trigger. When tool performance begins to diminish, stop

the tool and recharge the battery for optimal performance.

22. Charge battery pack at ambient temperatures between

50° F -104° F. Store tool and battery pack in locations

where temperatures will not exceed 120°F. This is

important to prevent serious damage to the battery cells.

23. Abattery operated tool with integral batteries or a

separate battery pack must be recharged only with the

specied charger for the battery. A charger that may be

suitable for one type of battery may create a risk of re

when used with another battery. Use battery operated

tool only with specically designated battery pack. Use of

any other batteries may create risk of re.

24. When battery pack is not in use, keep it away from other

metal objects, like paper clips, coins, keys, nails, screws

or other small metal objects, that can make a connec-

tion from one terminal to another. Shorting the battery

terminals together may cause burns or a re.

25. Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs,

ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

26. Prevent accidental starting. Ensure switch is in the “OFF”

position before connecting to power source and/or bat-

tery pack, picking up or carrying the tool. Carrying power

tools with your nger on the switch or energizing power

tools that have the switch “ON” invites accidents.

27. Do not use the power tool if the switch does not turn it on

and off.Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

28.

Have your power tool serviced by a qualied repair person

using only identical replacement parts. This will ensure

that the safety of the power tool is maintained. Follow

instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of shock or injury.

29.

Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments

or changing accessories. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

30. Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

31. Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control.

32. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.