3 4

1. Repairs must be performed by a qualified expert, using only identical replacement parts.

This will ensure that the safety of the tool is maintained.

2.

Remove the battery from tool and disconnect the charger from the wall outlet before cleaning

.

CLEANING

1. Keep protection devices, air vents and the motor housing as clean (dust free) as possible.

Clean the tool with a clean cloth or clean with compressed air at low pressure.

2. We recommend cleaning the tool directly after each use.

3.

Clean the tool regularly with a damp cloth and a little soap. Do not use any cleaner or

detergent, they can damage the plastic parts of the tool. Ensure that no water enters the tool.

MAINTENANCE

1. Recharge the battery at least once a year to maintain battery life.

ENVIRONMENTAL PROTECTION

This device uses electronic components, so they should not be deposited with household

garbage! Please help by collaborating to protect resources and the environment. Dispose of

these products through relevant recycling services, if any. For questions on this matter,

please contact your local waste management or a specialized site.

CARE AND MAINTENANCE

1. Keep the area clean and well lit. Cluttered or dark areas can cause accidents.

2. Do not use power tools in explosive environments, e.g. in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

3. Keep children and people away during the use of the tool. Distractions can cause you to

lose control of the tool.

WORKPLACE SECURITY

1. It is necessary that the power tool plugs are adapted to the base. Never modify the plug in

any way. Do not use adapters with earthed tools. Unmodified plugs and adapted bases

reduce the risk of electric shock.

2.

Avoid contact with grounded objects such as pipes, radiators, stoves and refrigerators.

There is an increased risk of electric shock if your body is in contact with grounded surfaces.

3. Do not expose power tools to rain or wet conditions. The penetration of water into a tool

increases the risk of electric shock.

4. Do not misuse the cable. Do not use the cord for carrying, pulling or unplugging the tool.

Keep the cord away from heat, oil, edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a tool outside, use an extension cord suitable for outdoor use. Using a

cable suitable for outdoor use reduces the risk of electric shock.

6. If it is necessary to use the tool in a location with moisture, use a secure supply with

residual current device (RCD). The use of an RCD reduces the risk of electric shock.

ELECTRICAL SAFETY

1. Be aware of what you are doing and use common sense while using the tool. Do not use a

tool when you are tired or under the influence of drugs, alcohol or medication. A moment of

distraction while using a tool can cause serious personal injury.

2. Use safety equipment. Always wear eye protection. Safety equipment such as dust masks,

non-slip safety shoes, helmets or ear protection used in appropriate conditions will reduce

the risk of injury.

3. Avoid accidental starting. Make sure that the switch is in the off position before plugging in

to power or battery, collect or transport. Carrying tools with your finger on the trigger or

plugging the tool in with the trigger pulled can cause accidents and injury.

4. Remove any adjusting key before turning the tool on. A key left attached to a rotating part of

the tool may result in personal injury.

5. Do not rush. Maintain proper footing and balance at all times. This allows better control of

the tool in unexpected situations.

6.

Dress appropriately. Do not wear loose clothing or jewelry. Keep hair, clothing and gloves

away from moving parts. Loose clothing, jewelry or long hair can get caught in moving parts.

7.

If devices for connecting equipment for extraction and dust collection are supplied, make sure

they are connected and properly used. Use of dust collection can reduce risks due to dust.

PERSONAL SAFETY

1. Do not use any other charger than the one specified by the manufacturer. A charger that fits

to a type of battery can cause a risk of fire when used with other types of batteries.

2. Do not use tools with batteries other than those specified. The use of any other type of

battery may create a risk of injury and fire.

3. If the batteries are not used, keep them away from other metal objects such as clips, coins,

keys, nails, screws or other small objects that can lead to a connection from one terminal to

another. Short-circuiting the terminals of a battery can cause burns or fire.

4. In bad conditions, liquid may be ejected from the battery; avoid any contact. In case of

accidental contact, flush with water. If the fluid comes into contact with eyes, seek medical

assistance. The ejected battery fluid may cause irritation or burns.

USING MACHINES WITH BATTERY AND PRECAUTIONS FOR USE

1.

Do not force the tool. Use the right tool to the application being performed. A suitable tool will

do the job better and more safely if used for the purpose for which it has been built.

2. Do not use the tool if the switch does not allow to turn it on or off. Any tool that can not be

controlled by the switch is dangerous and must be repaired.

USE AND MAINTENANCE OF THE TOOL

3. Disconnect the power source supply or battery block tool before changing accessories or

before storing the tool. These preventive safety measures reduce the risk of accidental

starting of the tool.

4. Keep the tool off away from children and do not allow to be used by people who are not

familiar with the tool. Tools are dangerous in the hands of inexperienced.

5.

Do not force the tool. Use the right tool for the application being performed. A suitable tool

will do the job better and more safely if used for the purpose for which it has been built.

6. Do not use the tool if the switch does not allow you to turn it on or off. Any tool that can not

be controlled by the switch is dangerous and must be repaired.

7. Disconnect the power supply and battery charger before changing accessories or before

storing the tool. These preventive safety measures reduce the risk of accidental starting of

the tool.

8. Keep the tool away from children and do not allow tool to be used by people who are not

familiar with the operation of the tool. Tools are dangerous in the hands of inexperienced

operators.

9. Make sure the tools moving parts are not aligned or blocked, that it has not broken any

parts or any other condition that may affect the operation of the tool. In case of damage,

take the tool to a repair service before using it again. Many accidents are caused by poorly

maintained tools.

10. Tools used for cutting, with sharp pieces that have had good maintenance, are less likely to

become blocked and are easier to control.

11. Use the tool, accessories and blades, etc. according to these instructions, taking into

account the working conditions and the work to be done. The use of the tool for operations

other than those provided can lead to dangerous situations.

USE AND MAINTENANCE OF THE TOOL

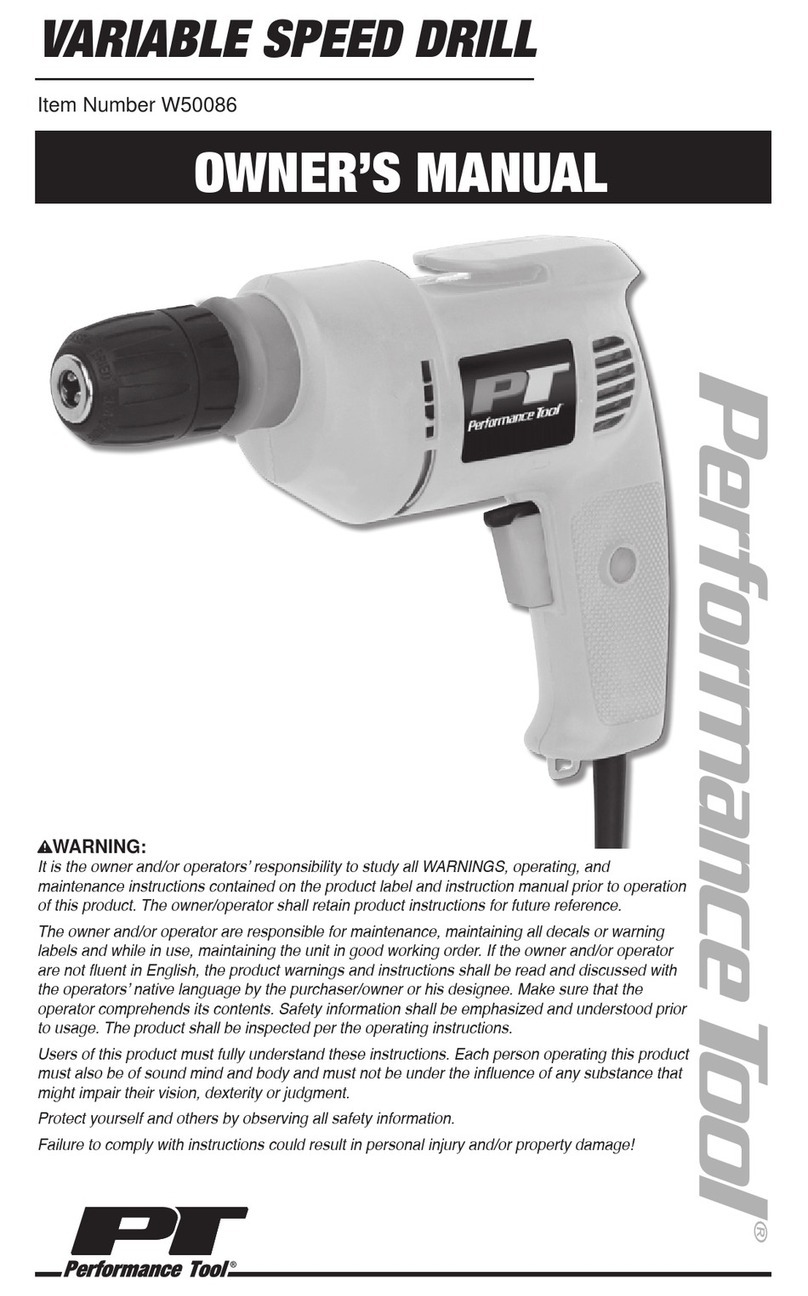

WARNING! READ, UNDERSTAND AND FOLLOW ALL

INSTRUCTIONS AND WARNINGS BEFORE OPERATING THIS

TOOL. FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY

AND/OR PROPERTY DAMAGE AND WILL VOID WARRANTY.