Contents

Contents ................................................................................. Chapter - Page

9Preparation .................................................................................................................. 9 - 1

9.01 Inserting the needle ...................................................................................................... 9 - 1

9.02 Winding the bobbin thread, adjusting the thread tension .............................................. 9 - 2

9.03 Removing/inserting the bobbin case ............................................................................. 9 - 3

9.04 Threading the bobbin case, adjusting the thread tension .............................................. 9 - 3

9.05 Threading the needle thread ......................................................................................... 9 - 4

9.06 Adjusting the needle-thread tension.............................................................................. 9 - 4

9.07 Pre-selecting the stitch length and fullnes .................................................................... 9 - 5

9.08 Entering the maximum speed ....................................................................................... 9 - 6

9.09 Entering the start and end backtacks ............................................................................ 9 - 6

9.10 Setting the edge guide .................................................................................................. 9 - 7

9.10.01 Mechanical edge guide (PFAFF 3827-4/33) ................................................................... 9 - 7

9.10.02 Pneumatic edge guide (PFAFF 3827-4/34) .................................................................... 9 - 7

10 Sewing ....................................................................................................................... 10 -1

10.01 Manual sewing (side seams) ....................................................................................... 10 - 1

10.02 Programmed sewing (shoulder seams) ....................................................................... 10 - 2

10.03 Examples of operating cycles ..................................................................................... 10 - 3

10.03.01 Sewing shoulder seams .............................................................................................. 10 - 3

10.03.02 Sewing side and shoulder seams in combination........................................................ 10 - 4

10.04 Error messages ........................................................................................................... 10 - 6

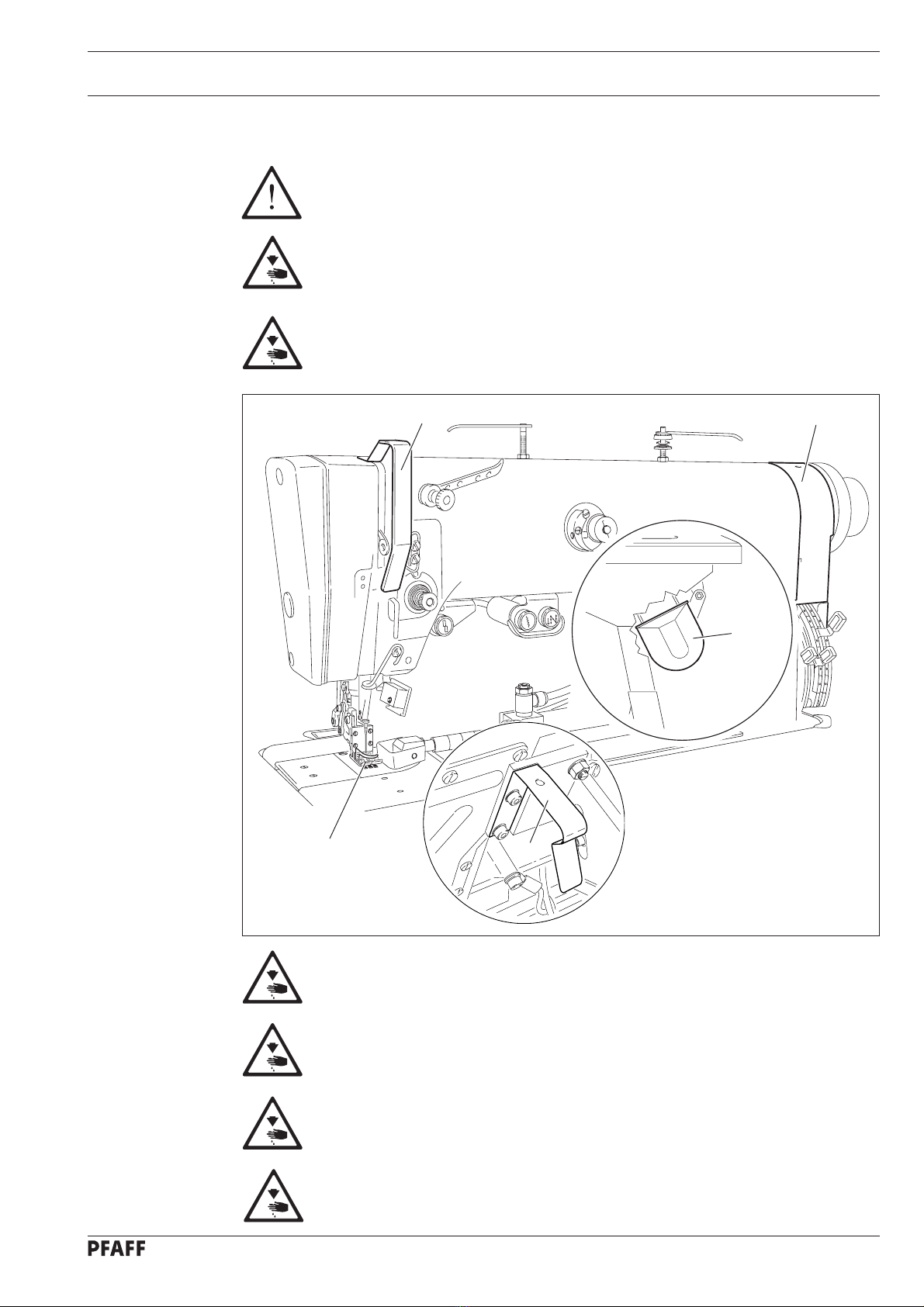

11 Care and Maintenance .............................................................................................. 11 - 1

11.01 Cleaning the machine.................................................................................................. 11 - 1

11.02 Oil level of the machine .............................................................................................. 11 - 2

11.03 Cleaning/lubricating the top feed joints ....................................................................... 11 - 2

11.04 Checking the air pressure ........................................................................................... 11 - 3

11.05 Emptying/cleaning the water container of the air filter/regulator ................................. 11 - 3

12 Adjustment ................................................................................................................ 12 - 1

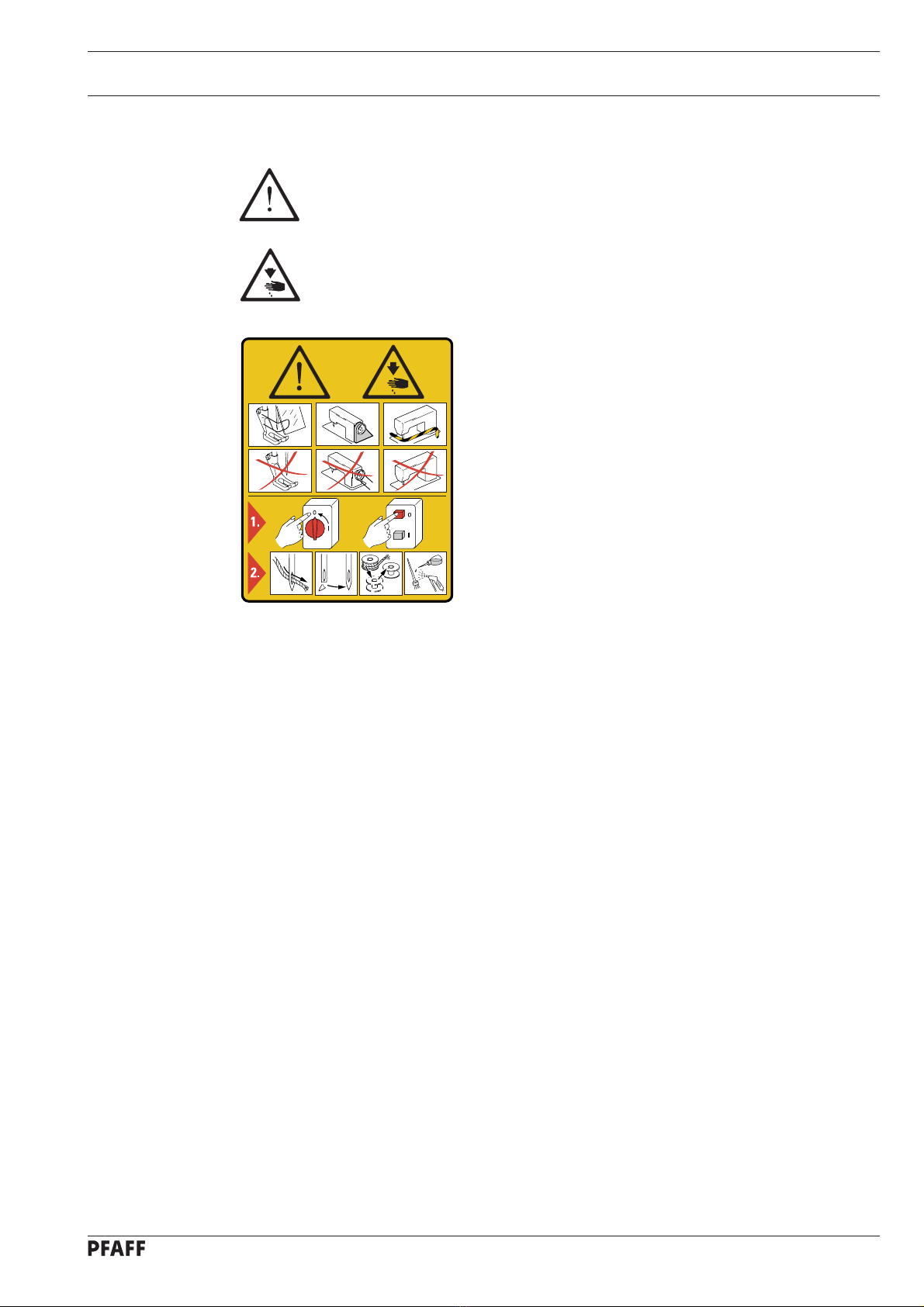

12.01 Notes on adjustment................................................................................................... 12 - 1

12.02 Tools, gauges and other accessories for adjusting ...................................................... 12 - 1

12.03 Abbreviations .............................................................................................................. 12 -1

12.04 Check and adjustment aid ........................................................................................... 12 - 2

12.05 Adjusting the basic machine ....................................................................................... 12 - 3

12.05.01 Basic position of the machine ..................................................................................... 12 - 3

12.05.02 Preliminary adjustment of the needle height ............................................................... 12 - 4

12.05.03 Needle in needle-hole centre....................................................................................... 12 - 5

12.05.04 Neutral position of the bottom feed dog ..................................................................... 12 - 6

12.05.05 Feeding motion of the bottom feed dog ..................................................................... 12 - 7

12.05.06 Lifting motion of the bottom feed dog ........................................................................ 12 - 8

12.05.07 Height of the bottom feed dog .................................................................................... 12 - 9

12.05.08 Clearance between presser foot and needle plate ...................................................... 12 - 10

12.05.09 Stop in relation to the presser foot .............................................................................. 12 - 12

12.05.10 Top feed driving and connecting lever......................................................................... 12 - 13

12.05.11 Neutral position of the top feed dog............................................................................ 12 - 14