Contents

Contents ...............................................................................Chapter - Page

13 Adjustment ............................................................................................................. 13 - 1

13.01 Tools, gauges and other accessories for adjusting................................................... 13 - 1

13.02 Abbreviations ........................................................................................................... 13 - 1

13.03 Explanation of the symbols ...................................................................................... 13 - 1

13.04 Checking and adjusting aids ..................................................................................... 13 - 2

13.05 Adjusting the basic machine .................................................................................... 13 - 3

13.05.01 Basic position of the machine drive ......................................................................... 13 - 3

13.05.02 Preadjusting the needle height................................................................................. 13 - 4

13.05.03 Bottom feed neutral position.................................................................................... 13 - 5

13.05.04 Neutral position of the needle feed (only on PFAFF 1181) ....................................... 13 - 6

13.05.05 Bottom feed lifting motion ....................................................................................... 13 - 7

13.05.06 Bottom feed dog height ........................................................................................... 13 - 8

13.05.07 Feed dog motion of bottom feed dog ...................................................................... 13 - 9

13.05.08 Feeding motion of needle feed (only on PFAFF 1181).............................................. 13 - 10

13.05.09 Needle in needle hole center (only on PFAFF 1183) ................................................. 13 - 11

13.05.10 Needle to needle hole centre (on PFAFF 1181) ........................................................ 13 -12

13.05.11 Synchronous strokes of needle- and drop feed (only on PFAFF 1181) ..................... 13 - 13

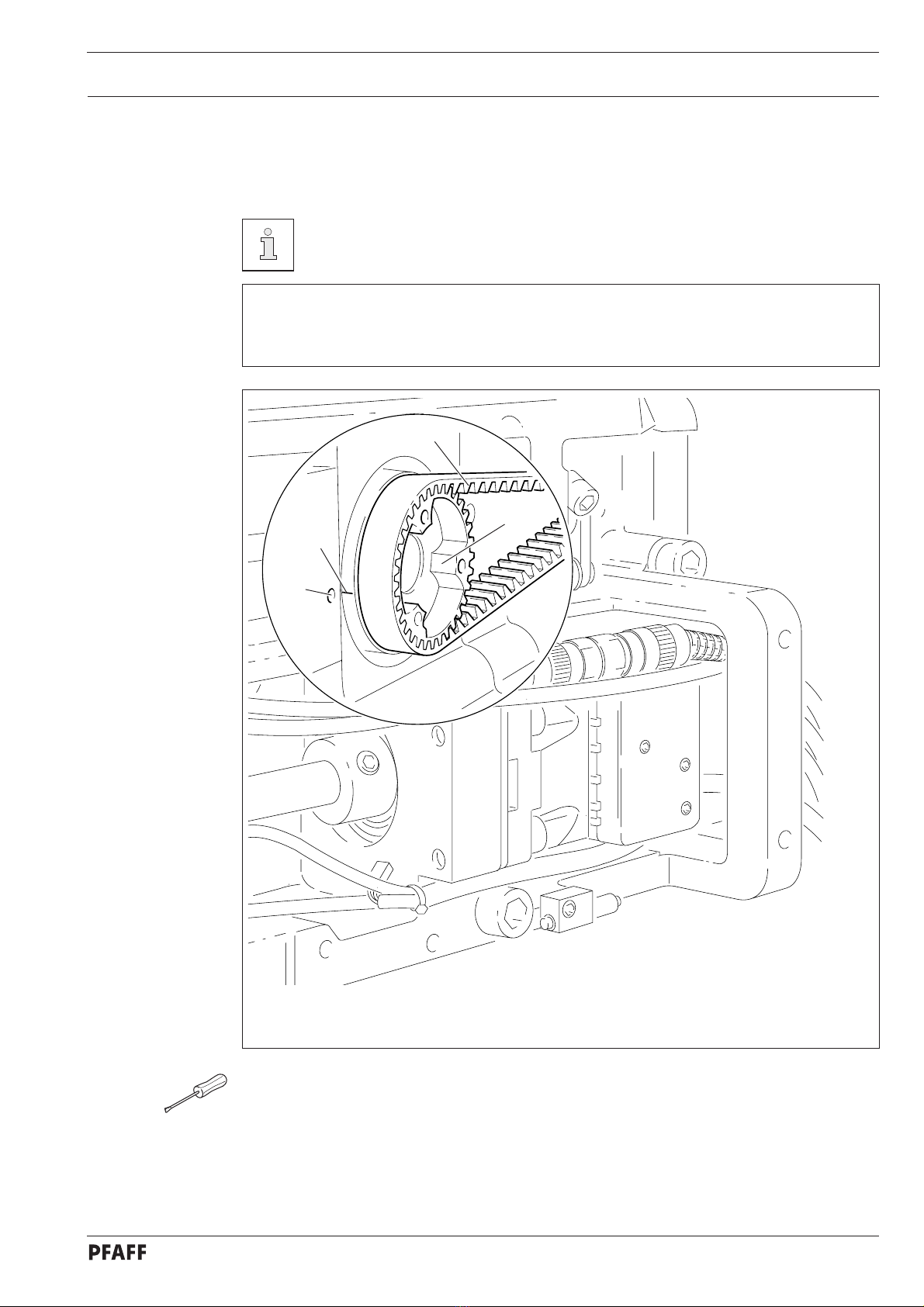

13.05.12 Hook shaft bearing and toothed belt tension ........................................................... 13 -14

13.05.13 Hook lubrication ....................................................................................................... 13 -15

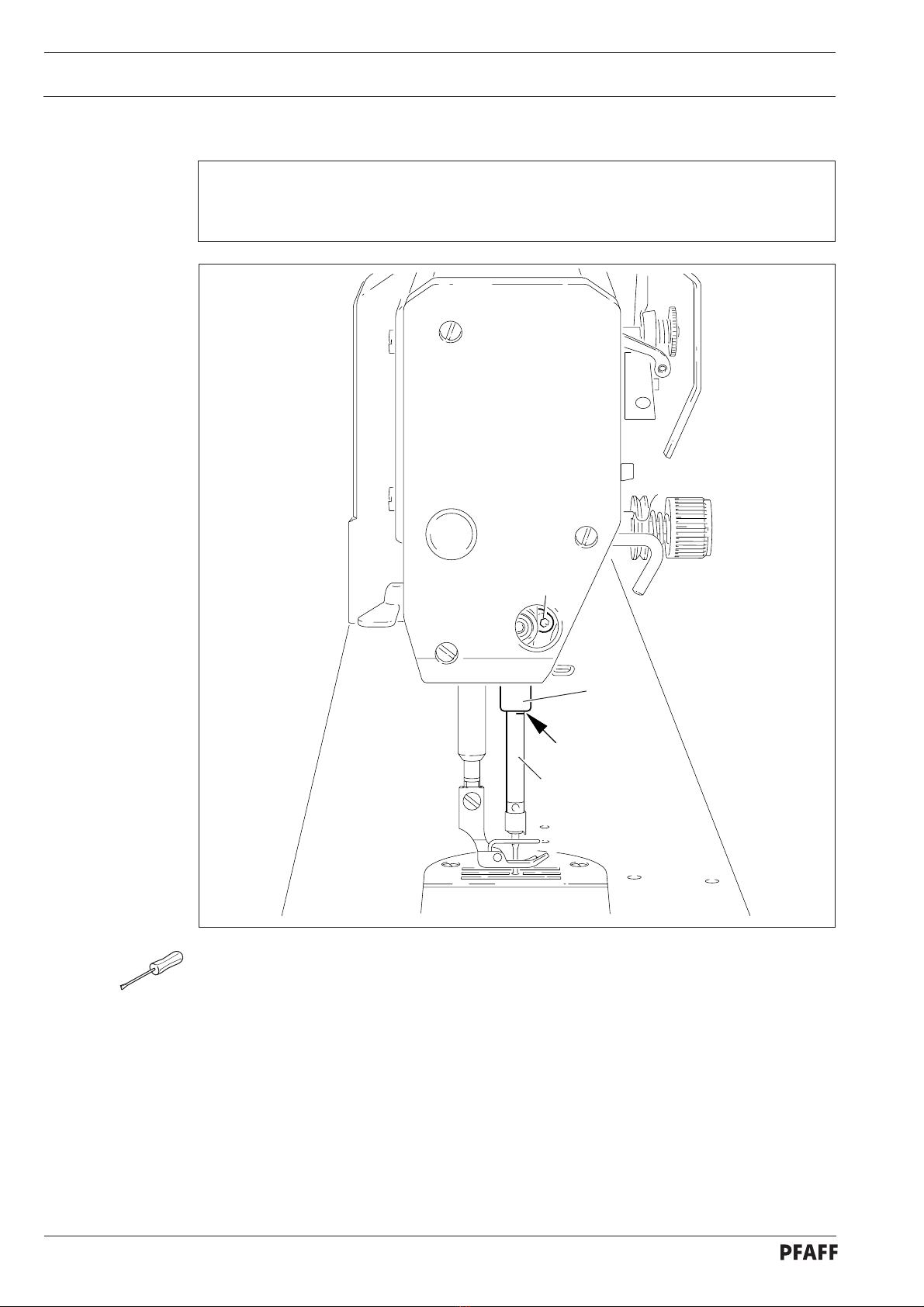

13.05.14 Needle rise, hook-to-needle clearance, needle height and bobbin case position finger 13 - 16

13.05.15 Thread check spring and slack thread regulator ....................................................... 13 -17

13.05.16 Position of knee lever............................................................................................... 13 - 18

13.05.17 Knee lever stop ........................................................................................................ 13 -19

13.05.18 Bobbin winder .......................................................................................................... 13 - 20

13.05.19 Limiting the stitch length.......................................................................................... 13 - 21

13.05.20 Stitch length adaptation ........................................................................................... 13 - 22

13.05.21 Presser foot pressure .............................................................................................. 13 -23

13.05.22 Modifying the needle bar stroke .............................................................................. 13 - 24

13.06 Adjusting the edge trimmer –731/01........................................................................ 13 - 25

13.06.01 Zero position of the knife ......................................................................................... 13 - 25

13.06.02 Cutting motion ......................................................................................................... 13 - 26

13.06.03 Knife height.............................................................................................................. 13 -27

13.06.04 Knife position in sewing direction............................................................................. 13 - 28

13.06.05 Knife position crosswise to sewing direction ........................................................... 13 - 29

13.07 Adjusting the thread trimming device -900/24.......................................................... 13 - 30

13.0.01 Adjusting the solenoid / preliminary adjustment of the control cam......................... 13 -30

13.07.02 Lateral alignment of the thread catcher ................................................................... 13 -31

13.07.03 Knife position ........................................................................................................... 13-32

13.07.04 Front point of reversal of the thread catcher ............................................................ 13 - 33

13.07.05 Manual trimming check............................................................................................ 13 - 34