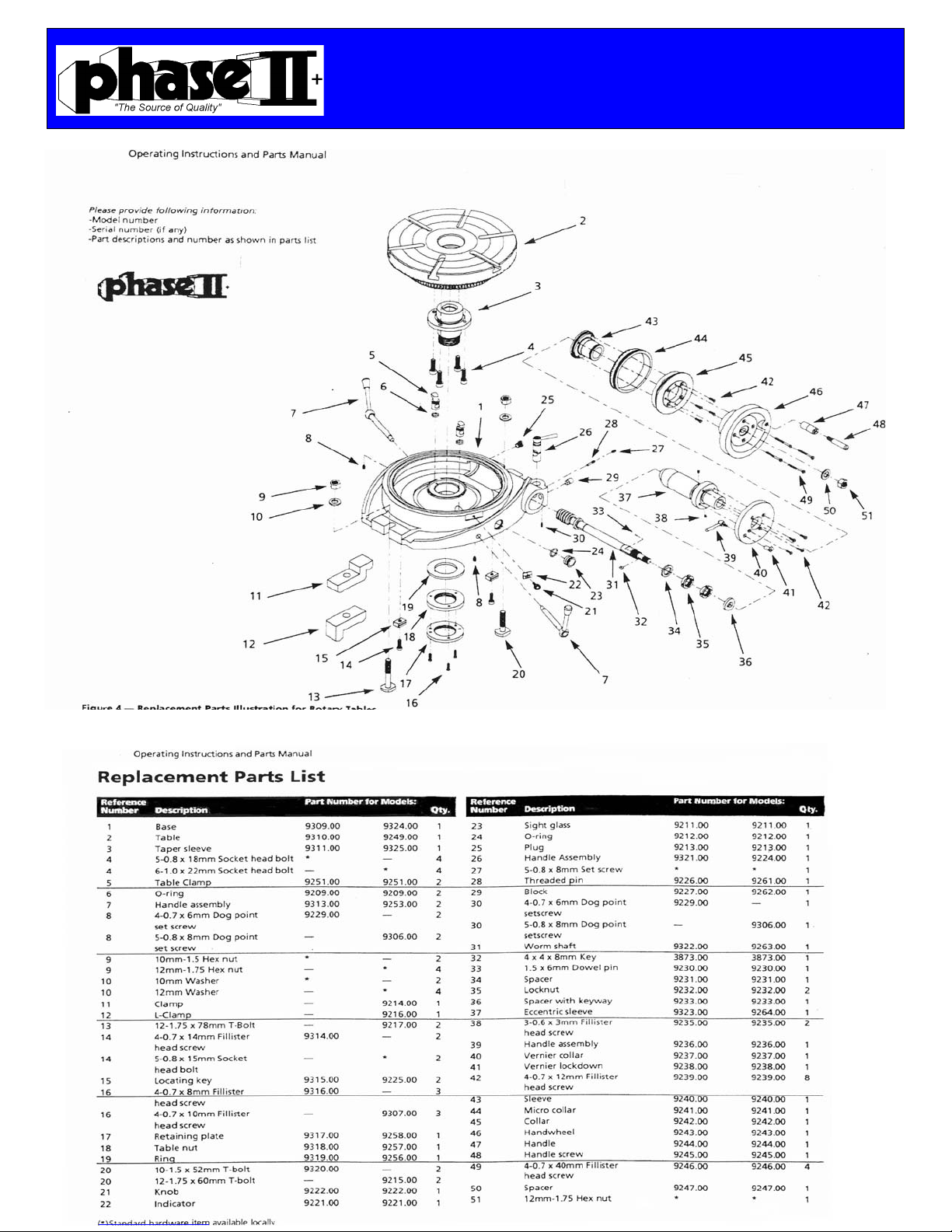

OperatingInstructions&PartsManual

HorizontalRotaryTables

DividingPlates

Pg. 2

Operating Instructions & Parts Manuals

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal

injury and or property damage! Retain instructions for future reference.

Description

ThePhaseIIhorizontalrotarytablesareusedfor

indexing,circularcutting,anglesetting,boringand

spotfacingoperations.Themeehanitecastiron

tableisprecisionmachinedandisprovidedwitha

MorseTapercenterhole.Thetableisgraduated

witha360scale.Amicrocollargraduatedtoone

minutewithatensecondaccuracyvernierscaleis

provided.Rotarytablefeaturesincludelock‐down

handlesandcrankdisengagementmechanism.

Wormgearandcenterholetaperarehardened

andground.Thedividingplatesaccessoryallows

theoperatortoaccuratelydividethe360rotation

oftheclampingsurfaceintodivisionsof2through

66,andalldivisiblesof2,3and5from67‐132.

Unpacking

Checkforshippingdamage.Ifdamagehasoccurred,a

claimmustbefiledwithcarrierimmediately.Checkfor

completeness.Immediatelyreportmissingpartsto

dealer.Carefullyremovetablefromcrate.

Important:Thetoolhasbeencoatedwithprotective

coating.Inordertoensureproperfitandoperationthe

coatingmustberemoved,removecoatingwithmild

solventssuchasmineralspiritsandasoftcloth.

Nonflammablesolventsarerecommended.After

cleaning,coverallexposedsurfaceswithalightcoating

ofoil.Besuretolubricatetableasdescribedin

"Maintenance"

Caution:Neverusehighlyvolatilesolvents.

Avoidgettingcleaningsolutiononpaint,asit

maytendtodeterioratethesefinishes.Use

soapandwateronpaintedcomponents.

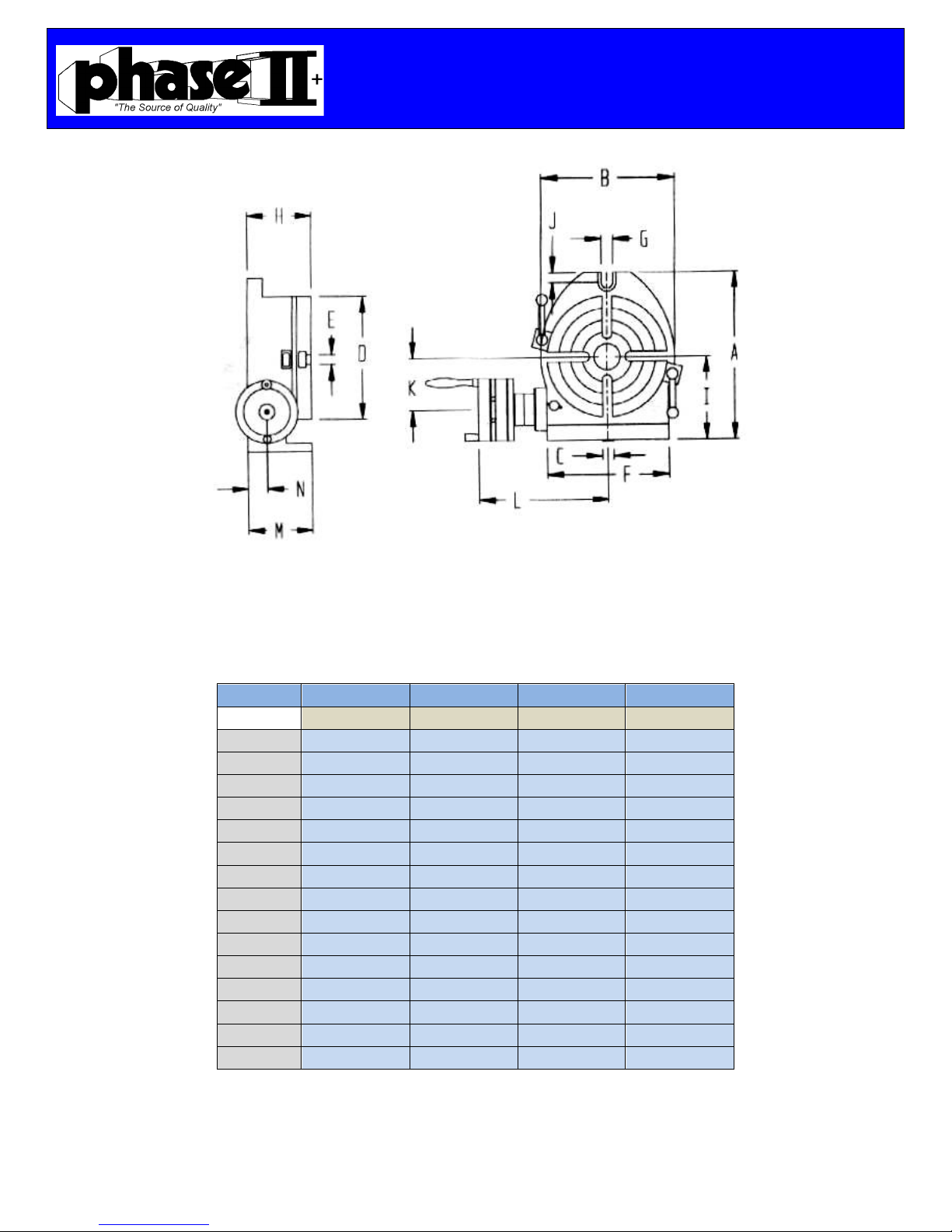

Specifications

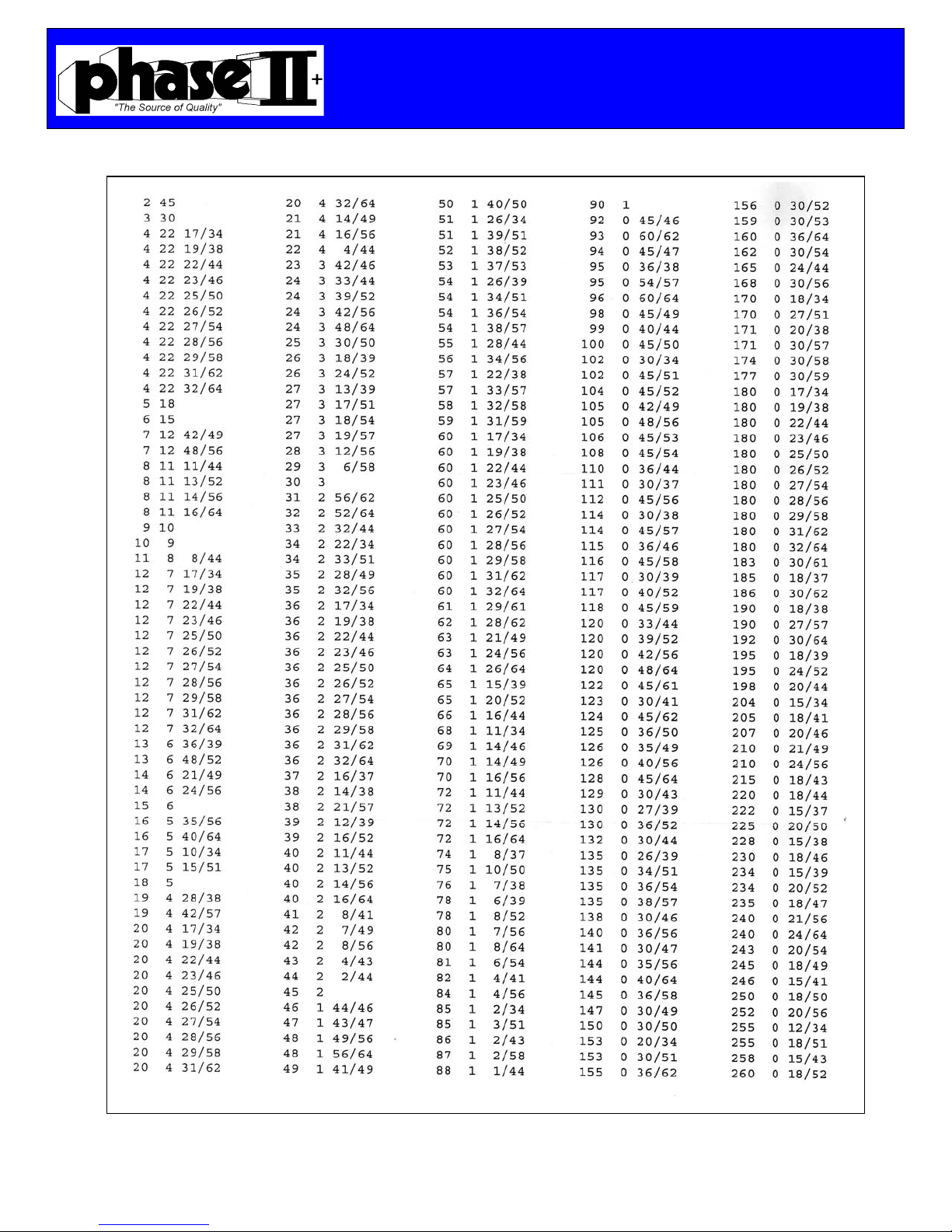

DividingPlatesAccessory

Possibledivisionsof

Onerotation:...................2thru66,andall

...............................................divisiblesof2,3,and5

...............................................from67‐132

Accuracy MaximumT.I.P.

Flatnessofclampingsurface.............................0.0006”

Parallelismofclamping

Surfacetobase.......................................................0.0008”

Squarnessofclampingsurface

toangleface............................................................0.0004"

Squarenessofclampingsurface

tocenterslot...........................................................0.0008"

Concentricityofcenterbore..............................0.0008"

Maximumspacingerror:

6”&8”.....................................1minute,20seconds

10”,12”&16”.........................45seconds

GeneralSafetyInformation

1. Readandfollowalloperatinginstructionbeforeoperating

rotarytable.

2. Understandandobeyallsafetyinstructionssuppliedwithmill

orothermachinesonwhichtherotarytableisused.

3. Alwayssecurerotarytabletoworksurfaceorothermachine.

4. Alwayssecureworkpiecetorotarytableclampingsurfaceif

used.

5. Alwayssecurefaceplatetorotarytableclampingsurfaceif

used.

6. Alwayssecurerotarytableclampingsurfacewithlock‐down

handleswhenpossible.

7. Maintainandlubricatetoolproperly.

Installation

1. Mountrotarytablesecurelytomachineworksurface.

2. Useslotsprovidedontableandbesurethattableis

rigidlyandsafelysecured.

3. Tablecanonlybemountedhorizontallywithslots

provided.

Lubrication

Keeprotarytablecleanofdirtorchips.

Beforeputtingintouse,fillbasecavitywith

oilusingtheoilzertsonbase,tableandoil

plug(RefNo.11).UnscrewoilPlugpriorto

lubrication.Beforeeveryshiftofoperationfill

adequateoilthroughoilzertsandoilplug.

LUBRICATEWITHLIGHTDUTY

HYDRAULICFLUIDORSPINDLEOIL.Table

shouldbefilledwithoiluntilititvisiblein

thesightglass,donotoverfill.

Frequentlycheckoillevelusingsightglass

(Ref.No.8)Donotuserotarytablewithout

adequateoil.