Important Safety

Warnings & Instructions

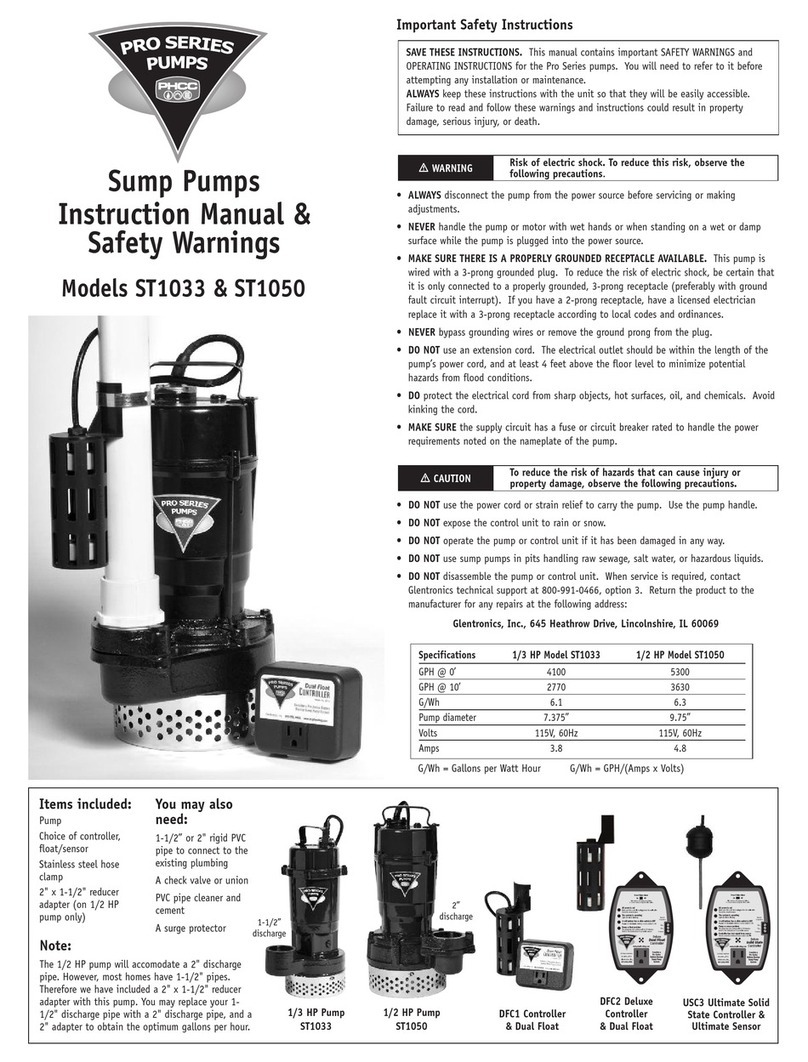

SAVE THESE INSTRUCTIONS. This manual

contains important SAFETY WARNINGS and

OPERATING INSTRUCTIONS for the Pro Series

battery backup sump pump system. You will

need to refer to it before attempting any

installation or maintenance. ALWAYS keep these

instructions with the unit so that they will be

easily accessible.

Failure to read and follow these warnings and

instructions could result in property damage,

serious injury, or death. It is important to read

this manual, even if you did not install the Pro

Series backup sump pump, since this manual

contains safety information regarding the use

and maintenance of this product. DO NOT

DISCARD THIS MANUAL.

ELECTRICAL PRECAUTIONS

Risk of electrical and fire hazard. May result

in death, serious injury, shock or burns.

To help reduce these risks, observe the

following precautions:

• DO NOT walk on wet areas of the basement

until all power has been turned off. If the

main power supply is in a wet basement, call

an electrician.

• NEVER handle the control unit with wet hands

or while standing on a wet surface.

• ALWAYS unplug the control unit and dis-

connect the cables from the battery before

attempting any maintenance or cleaning.

• ALWAYS unplug the main pump when instal-

ling or servicing the backup pump to avoid

electric shock.

• DO NOT expose the control unit to rain or

snow.

• Pull the plug rather than the cord when

disconnecting the control unit.

• An extension cord should not be used unless

absolutely necessary. If an extension cord

must be used, be sure the plug has the same

configuration as the plug on the control unit.

• Use of an attachment not recommended or

sold by the manufacturer may result in a risk

of fire or injury from an electrical shock.

• DO NOT operate the computer control unit if it

has received a sharp blow, been dropped, or

otherwise damaged in any way. Contact

Glentronics technical support at 800-991-

0466, option #3.

• DO NOT disassemble the control unit. When

service is required, contact Glentronics tech-

nical support at 800-991-0466, option #3.

Return the control unit to the manufacturer for

any repairs at the following address:

Glentronics, Inc.

640 Heathrow Drive

Lincolnshire, IL 60069

BATTERY PREPARATION

Sulfuric acid can cause blindness or severe

burns. Avoid contact with skin, eyes or

clothing. In the event of accident, flush

with water and call a physician immediately.

KEEP OUT OF REACH OF CHILDREN.

To help reduce these risks, observe the

following precautions:

• Someone should be within range of your voice

or close enough to come to your aid when you

work near a lead-acid battery.

• Have plenty of fresh water and soap nearby in

case battery acid contacts skin, clothing or

eyes.

• Wear eye and clothing protection and avoid

touching your eyes while working with battery

acid or working near the battery.

• If battery acid contacts skin or clothing, wash

immediately with soap and water. If acid

enters eye, immediately flood eye with run-

ning cold water for at least 10 minutes and get

medical attention.

• Battery posts and terminals contain lead and

lead compounds, chemicals known to the State

of California to cause cancer and reproductive

harm. Wash hands after handling.

BATTERY PRECAUTIONS

Explosive gases could cause serious injury

or death. Cigarettes, flames or sparks could

cause battery to explode in enclosed spaces.

Charge in well-ventilated area. Always

shield eyes and face from battery. Keep

vent caps tight and level.

To help reduce these risks, observe the

following precautions:

• NEVER smoke or allow a spark or flame in the

vicinity of the battery.

• Use the Pro Series control unit for charging a

LEAD-ACID battery only. Do not use the

control unit for charging dry-cell batteries that

are most commonly used with home

appliances.

• Be sure the area around the battery is well

ventilated.

• When cleaning or adding water to the battery,

first fan the top of the battery with a piece of

cardboard or another non-metallicmaterial to

blow away any hydrogen or oxygen gas that

may have been emitted from the battery.

• DO NOT drop a metal tool onto the battery. It

might spark or short-circuit the battery and

cause an explosion.

• Remove personal metal items such as rings,

bracelets, watches, etc. when working with a

lead-acid battery. A short circuit through one

of these items can melt it causing a severe

burn.

• ALWAYS remove the power cord from the

electrical outlet before connecting or

disconnecting the battery cables. Never allow

the rings to touch each other.

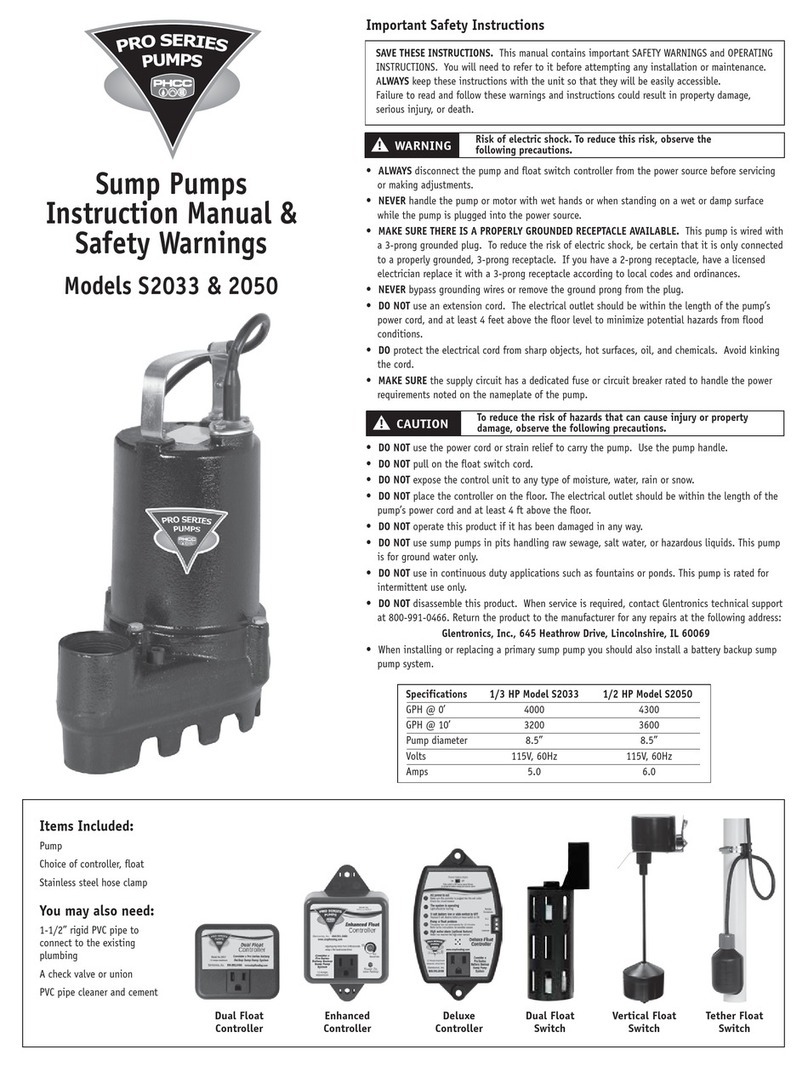

• Check the polarity of the battery posts. The

POSITIVE (+) battery post usually has a larger

diameter than the NEGATIVE (-) post.

• When connecting the battery cables, first

connect the small ring on the end of the

WHITE wire to the NEGATIVE (-) post of the

battery, and then connect the large ring on

end of the BLACK wire to the POSITIVE (+) post

of the battery.

Do not use system to pump flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc.

Page 1

!DANGER

!DANGER

!WARNING / POISON

!DANGER

POSITIVE POST HAS

LARGER DIAMETER NEGATIVE POST HAS

SMALLER DIAMETER

POSITIVE

POST NEGATIVE

POST