Philips DVP620VR User manual

Other Philips DVD Player manuals

Philips

Philips SVD100 User manual

Philips

Philips DVP640 User manual

Philips

Philips DVD-712 User manual

Philips

Philips DVP3142 User manual

Philips

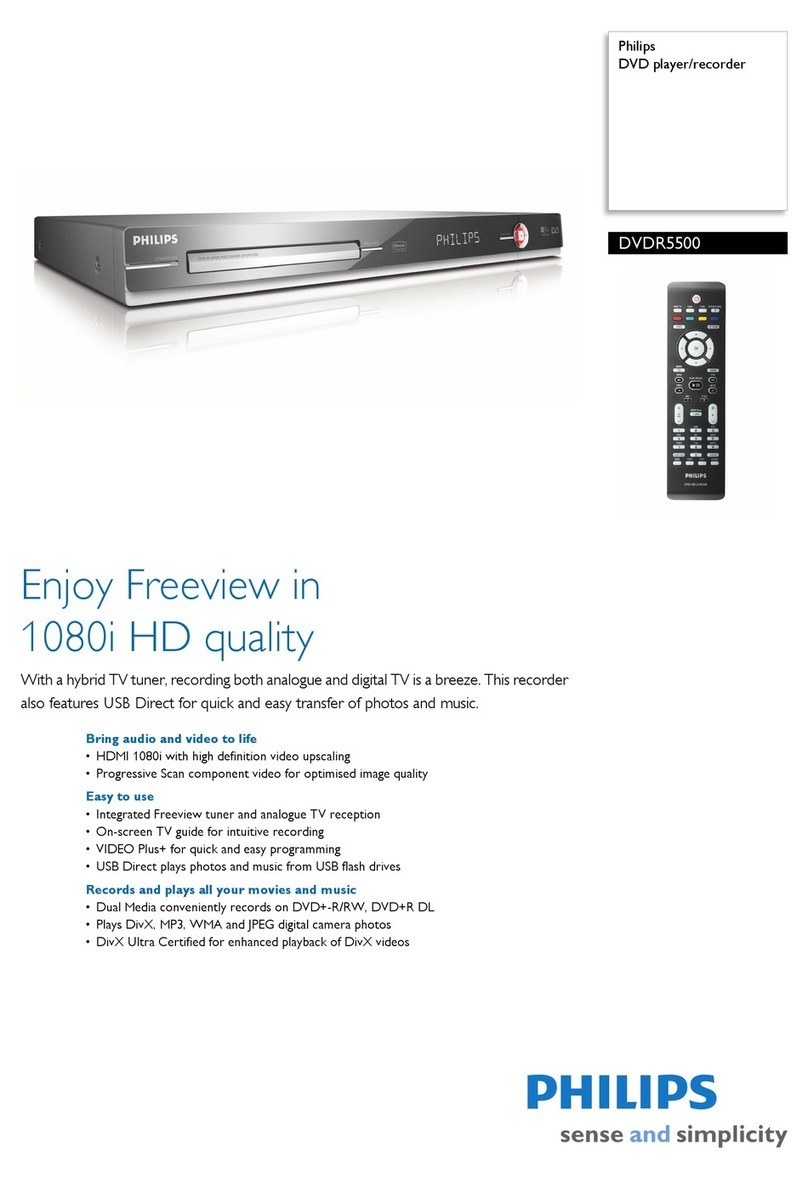

Philips DVDR5500 User manual

Philips

Philips DVP2320 User manual

Philips

Philips DVP3260K/98 User manual

Philips

Philips DVD1010 User manual

Philips

Philips SL-0314/00a-5 User manual

Philips

Philips DVP2320BU User manual

Philips

Philips DVDQ50/051 User manual

Philips

Philips DVP3850K/96 User manual

Philips

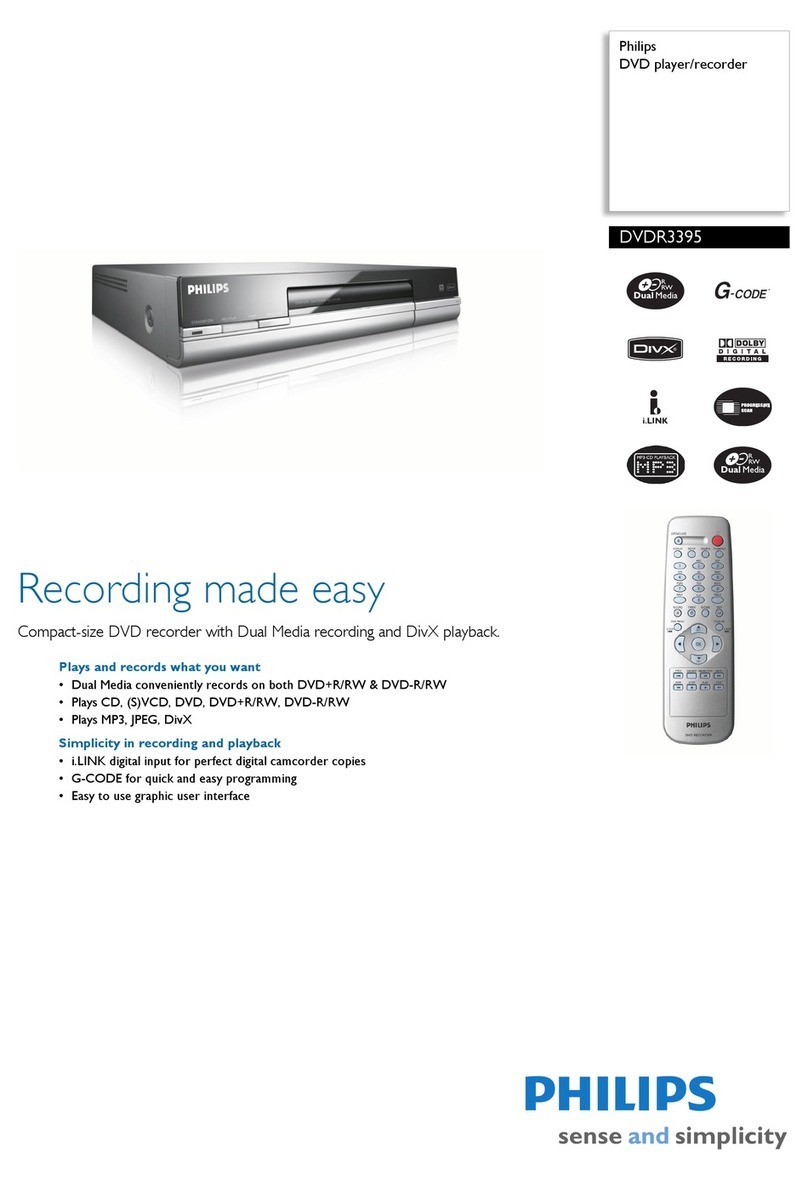

Philips G-Code DVDR3395 User manual

Philips

Philips DVP3560 User manual

Philips

Philips DVP3126K/98 User manual

Philips

Philips DVP3610 User manual

Philips

Philips DVP5990K/55 User manual

Philips

Philips DVD704 User manual

Philips

Philips DVD963SA/051 Operating manual

Philips

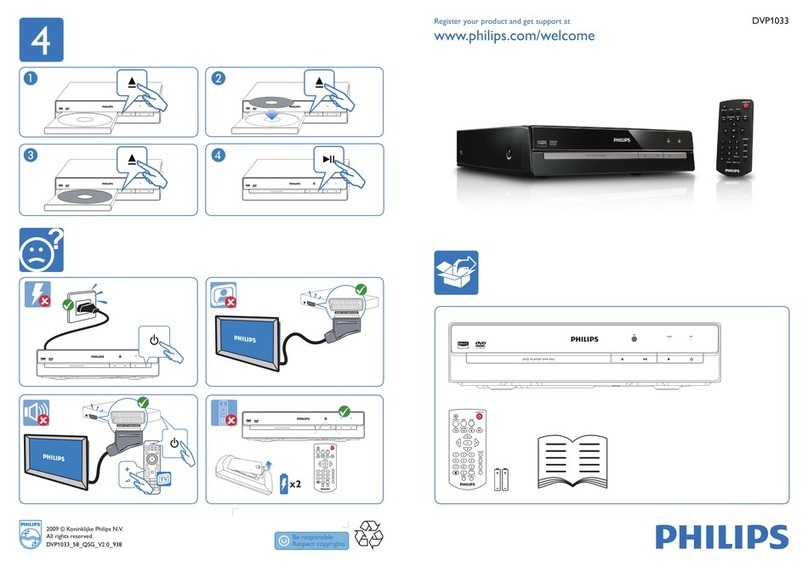

Philips DVP1033 User manual