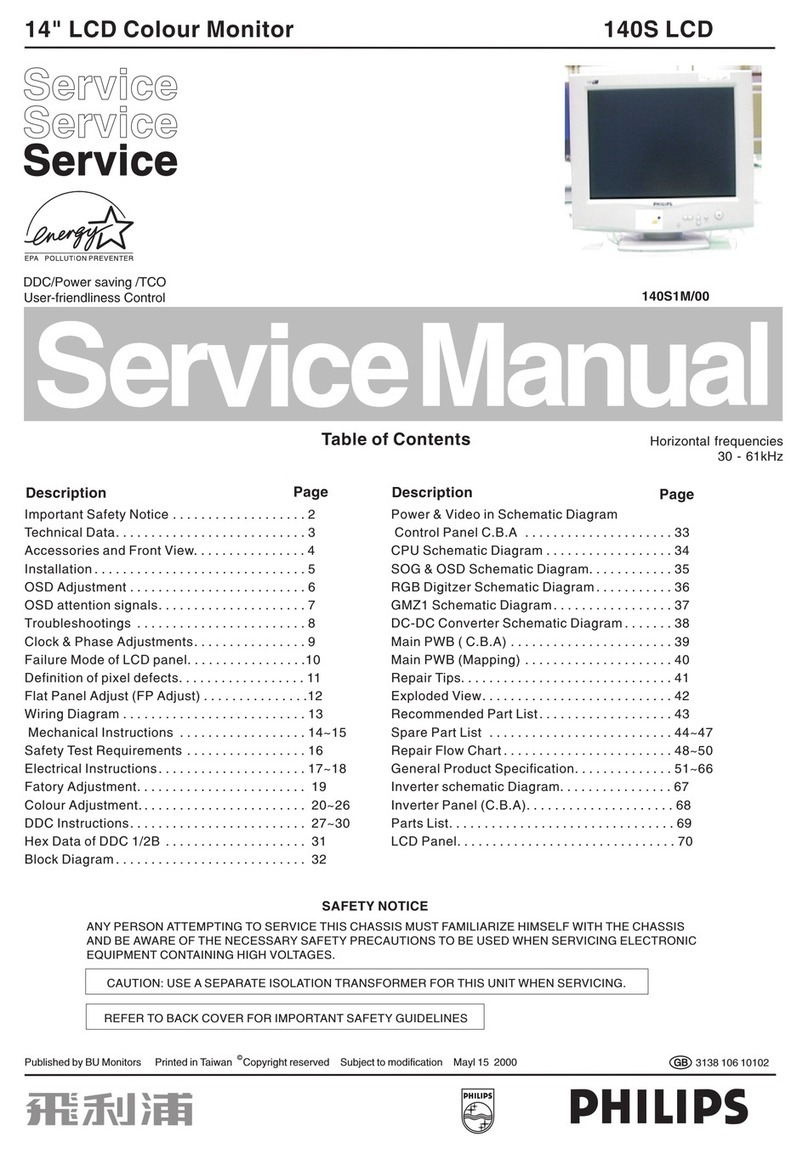

Table

of

Contents

Part

I:

Monitor

Operations

1

Monitor

Overview

...cccccccosncscsessceserescnsssssssessssensesseesceseessssesecensssnscnsseosssseeee

Lod

1.1

Block

Diagram..........sccssssssssecsssssssssenssenscnssnonecssensasencocsnsssensaseosenseses

1-1

1.2

Monitor

Specifications

........sscssscsssspsessscssscnssnsenssssenseessenensenssenecences

1-3

2

Power

Supply

&

Degauss

Circuitry

......cc.sccnsssssnsecsnsscsssssnesssnscensosensveseee

S71

2.1

Power

Supply

.........sccoscscsssorsrssessessecessnssssenssessncsssncsssnssssncersneesnssnesess

2-1

2.2

CHOPPED

......snssccsscsscscecsssceserssesesessnessnsssanessnecensssessnnsnsseucssnesasecusenseanes

2-3

2.3

Degaussing

Circuit

......ccsscsscssrssssenssnssseseneseossscecsncsnssesseesens

sapnruren

2-6

3

Deflection

Board

.......c.scsscccecscsssesseessnssnssssssssessesssessessnscnssvesseseesensenssnesensee

J”

3.1

Horizontal

Deflection

...........sssscssssssssesscsscssscsescsenenensncnsenecscsssnsensess

3-1

3.2

ET

Stabilization

Circiiit

.........ssccscsssscscrsssssescsssrsesercerssenssnenonses

wee

7D

3.3

Vertical

Deflection

...........cssssscssssscssssssscsecsssesessensasenerensseeensecsnserseees

3-4

3.4

Auxiliary

Services

......scssscscsssssessnesesssnsssnsssnsensenssssonssossssseceneeanerneees

3-4

4

Video

Preamplifier

Board

......ssscssssssssssrsssenesenesssenssessncenssnsensensssecsosenees

4-1

4.1

Video

Preamplifiers..........scscsersssecsecseees

wuic

bia

sundae

Gatpesasispaanunisats

4-1

4.2

Synchronization

........csssscessersssessscssenceeesnssersnssencssstensarensnssernenssnsencnssees

4-2

5

Video

Output

Stages

(Socket

Board)

.......rcccsssscssecssscsecsssssnenscsesseseoneneee

5-1

5.1

Fimal

Video

Stage

.......s.sscsssssssssssscerecssssssessnsesensnenssecececsescescssanesrensnese

5-1

5.2

Black

Level

Adjustment

and

Individual

Beam

Limiting.............

5-1

5.3.

Flashover

Protection

.........0+s+0

svoscecaeananencnnennennsenncssnssssnnnnnneneecngte

5-1

6

Dynamic

Focus

Board

....-.-.serscsssscscssesccssereencencsessceresees

wee

21

Part

II:

Adjustment

Procedures

7

Equipment

Needed

for

Adjustments

.......cccessocsrsscsrssesesesenesnencanensenseoes

7-1

S

Synchromization

.........ccscscssrssenesecsceressovsresssserssqnenenensevassesensnsssssenansevecsorese

8-1

Q

EHT

Stabilization

.........cscssscscscssrsccsesnccerssensssserscsncensensosconsonsscsensccseesnsonses

9-1

10

Geometry

......ccsccccscccsseseresnseseneseessrnssserenssosssenesessessoeseesesneacansesacaesnsnssoooeees

10-1

11

Chromaticity

..........ccccscsecccscerssererecesersonosonsncoessssenessssesecnsecsssrecesssonsnononeaes

11-1

12

Focus

NOE

ATT

ST

ARAN

LE

RN

ICES

ETE

ETON

TOE

13

Troubleshooting

.....cc..csecccsssssseeccsssossssssssesersseseesssnesenssssnsecnsssanessnscseeseseseee

LI~

1

13.1

OWOTVIEW

ccscasccceccacsccecsonsesseacassccssveseossseosasncscansnnseasesseessentinssanssecsnscoss

13-1

13D

TMGICATOTS

vcosivcesssensdnnsschicicaricpesebcaselecace

ewes

tnnedanseedchishadesnesennnsaesoutered

13-1

Appendix

A:

Monitor

Diagrams

.......s--ssesssssessnssressenensssersenensseenenrensansnssosecsenses

A-1

Appendix

B:

Layout

Diagrams...

sinbstheatedsnsiaaaustaabeaiebennesteneeseiovcctabasectatarensuene

B-1