Handling and Fitting Manual for semi-flexible solar panels EFLX series

Page 7 of 12

Gluing with double-sided tape

We recommend an industrial grade porous (“foam”) tape for this application. Applying

the tape across the entirety of the underside of the solar panel will improve the bond

quality.

When gluing with double-sided tape:

•Apply the tape onto the solar panel first, by “unrolling” it on the solar panel. Use

a soft cloth or a roller to gently apply pressure onto the tape (protective film side)

to dispel all air from between the tape and the solar panel. Take care not to force

the solar panel to bend underneath.

•If the length / width of the tape exceeds the solar panel, cut the tape carefully

around the edges of the solar panel.

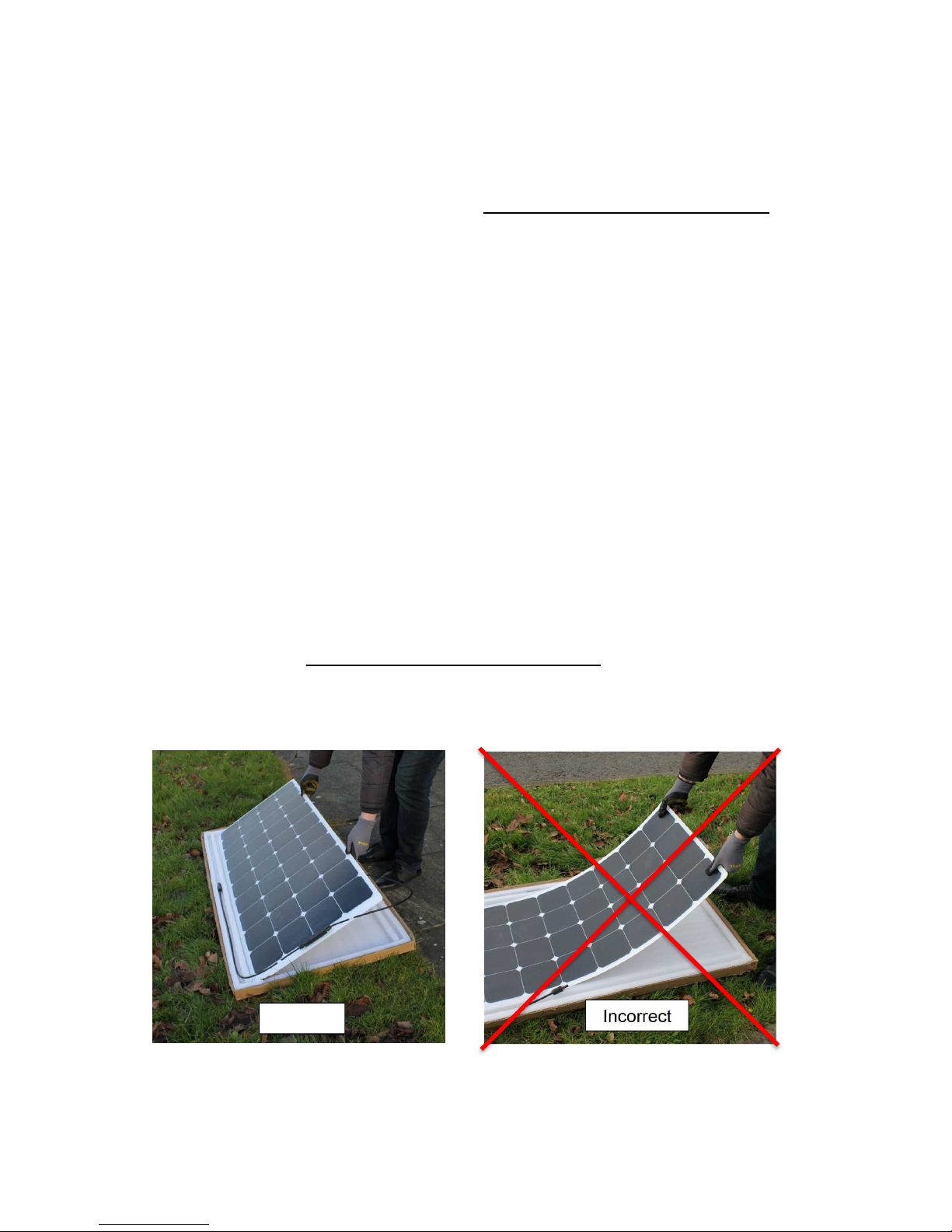

•Remove the protective film and stick the solar panel down on a clean and dry

surface, keeping the solar panel as straight as possible up until the final

moment when it takes the curved shape of the mounting surface. While sticking

it down, gently apply pressure on the solar panel with a soft cloth or a roller to

ensure that no air is trapped underneath the solar panel (2 people are

recommended for the installation).

•Observe the required application temperature for the double-sided tape and the

time for the glue to dry.

Warning! Double-sided adhesive tape forms a very strong immediate bond with the

contact material and does not allow for repositioning. Attempting to remove the solar

panel, even if only partially attached, can seriously damage the solar cells.

Gluing with adhesive

Your chosen adhesive should be suitable for both the solar panel and the mounting

surface. It should also be designed for outdoor applications (with a wide temperature

range, UV light protection etc). Pay attention to the application temperature and drying

time requirements.

The mounting surface must be even, clean (use a degreasing agent) and dry. The

installation must be carried out with care and precision, as this permanent method does

not allow for repositioning.

Warning! Although preparing the roof surface for better adhesion is permitted (if

required, e.g. by removing the old paint, grinding, using a primer etc), you must not use

any sand paper or other sharp or abrasive tools on the underside of the solar panel.

One of the most important things to bear in mind when gluing the solar panel using

adhesive is to ensure that there are no pockets of trapped air underneath the solar

panel, i.e. no void spaces with air that are sealed all the way around with adhesive. If

you leave trapped air under the solar panel (no matter whether it is between beads of

adhesive or in various slots and holes of the uneven roof surface), such air will inevitably

warm up when the solar panel is receiving good sunlight. When the air gets hot, it will

significantly expand in volume, causing upward pressure to the solar panel surface and

possible bulging of the solar panel during hot weather. This can result in permanent

damage to the solar cells.