PICHLER Kunststofftechnik GmbH

C

Co

on

nt

te

en

nt

ts

s

Placement..................................................................................................... 3

Electricity Supply......................................................................................... 3

Safety and Health......................................................................................... 3

Initial Operation ........................................................................................... 4

Preparing the Filter Unit .......................................................................................................4

Filter rmaterial of Pichler-QC-Filtersystem....................................................................................... 4

Water Treatment..................................................................................................................5

Pool Care...................................................................................................... 5

Placing out of Operation ............................................................................. 7

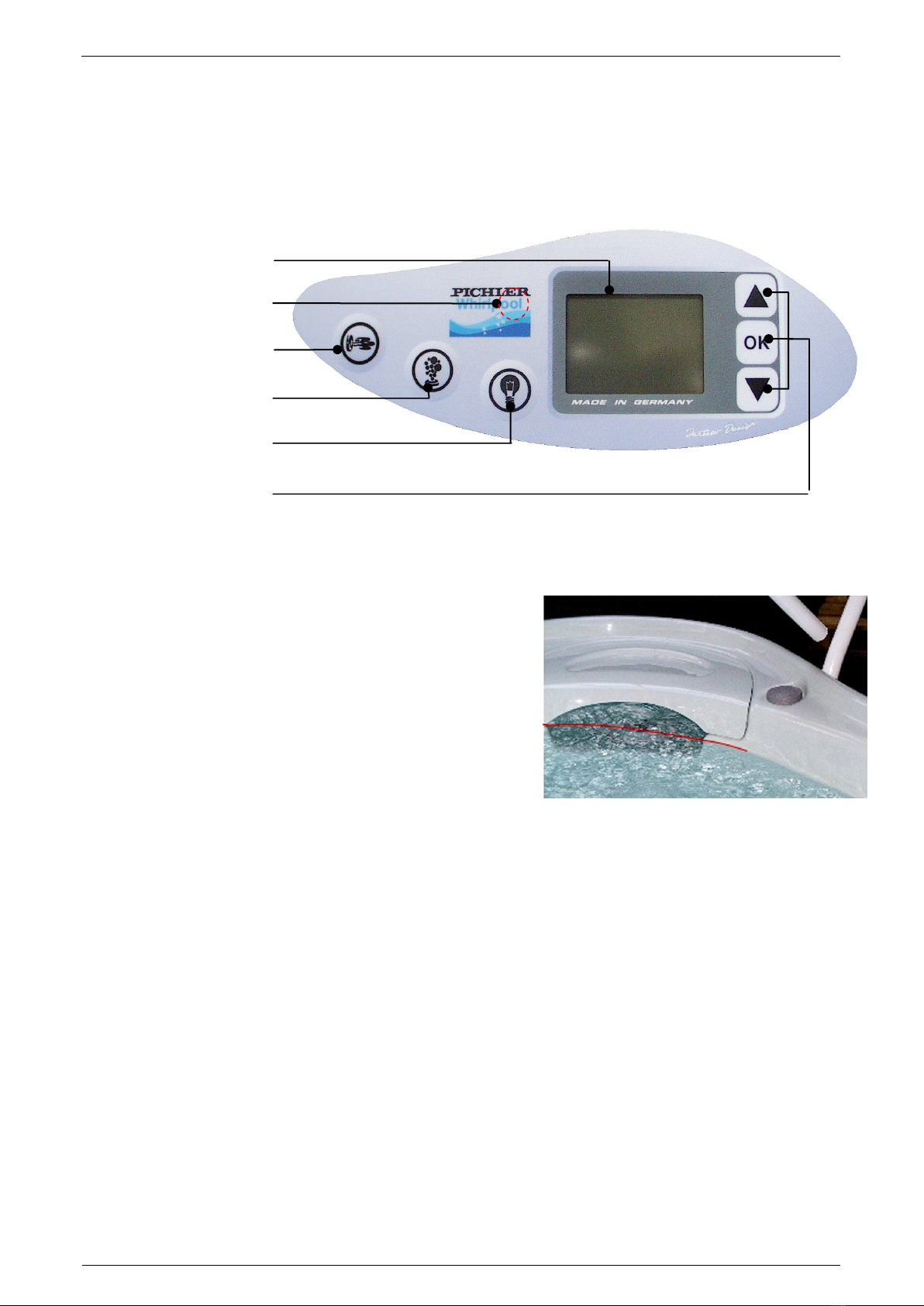

Whirlpool Controller .................................................................................... 8

Automatically functions ...................................................................................8

Trouble Shooting ...................................................................................11,13

Equipment Sania 1550............................................................................... 19

Controlling jet output with electrical valve control ..............................................................20

Massage jets......................................................................................................................21

Coloured Light Therapy Module (optionally) ......................................................................23

Service-Illumination (optionally) .........................................................................................23

Technical Specifications ........................................................................... 24

Plug on the whirlpool on electric power supply ..................................................................24

Wiring diagram of strip terminal Sania 1550 (three-phase current 400V) ............................ 25

Wiring diagram of strip terminal Sania 1550 (AC current 230V)............................................ 25

Layout Power Board................................................................................................................... 26

Manual of Automatic Spa Water Treatment System.................................27