Do

eivin

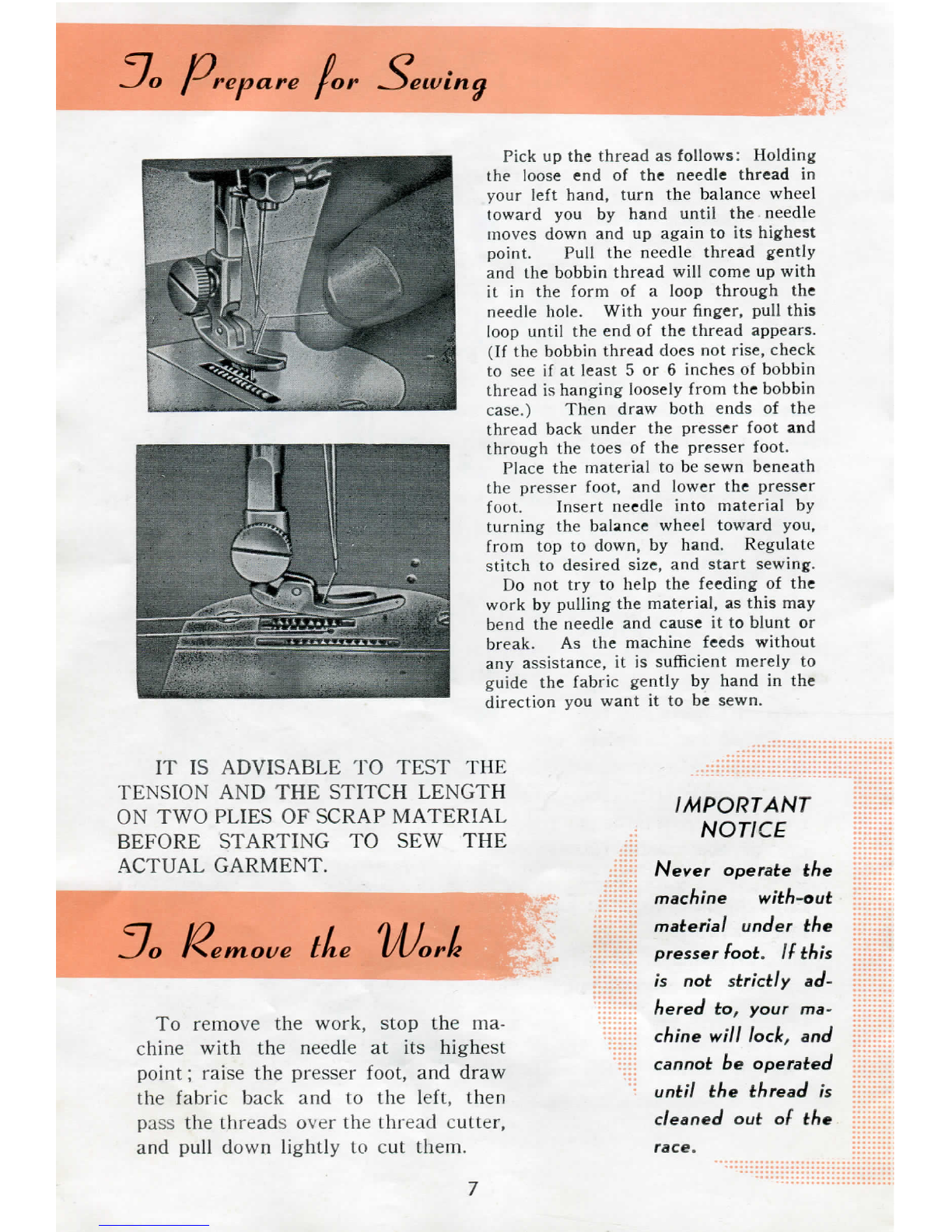

Pickupthethreadasfollows:Holding

the

loose

endofthe

needle

threadin

yourlefthand,

turn

the

balance

wheel

toward

youbyhand

until

the

needle

moves

downandup

again

toitshighest

point.

Pullthe

needle

threadgently

andthebobbinthread

will

come

up

with

it

intheformofa loopthroughthe

needle

hole.Withyourfinger,

pull

this

loop

until

theendofthethread

appears.

(If

thebobbinthread

does

notrise,

check

to

seeifatleast5 or6

inches

ofbobbin

threadishanginglooselyfromthebobbin

case.)

Thendrawboth

ends

ofthe

thread

back

underthepresserfootand

through

the

toes

ofthepresserfoot.

Place

thematerialtobesewnbeneath

thepresserfoot,andlowerthepresser

foot.

Insert

needle

intomaterialby

turning

the

balance

wheeltowardyou,

from

toptodown,byhand.

Regulate

stitch

todesired

size,

andstartsewing.

Donottrytohelpthe feedingofthe

work

bypullingthe material,asthismay

bendthe

needle

and

cause

ittobluntor

break.Asthemachine

feeds

without

any

assistance,

itissufficientmerelyto

guidethefabricgentlybyhandinthe

direction

youwantittobesewn.

IT

IS

ADVISABLE

TO

TEST

THE

TENSION

ANDTHE

STITCH

LENGTH

ONTWO

PLIES

OF

SCRAP

MATERIAL

BEFORE

STARTING

TOSEWTHE

ACTUAL

GARMENT.

Remove

tite lAJorii

Toremovethework,stopthema-

chine

with

the

needle

atitshighest

point;

raisethepresserfoot,anddraw

thefabric

back

andtotheleft,then

pass

thethreadsoverthethreadcutter,

and

pull

downlightlytocutthem.

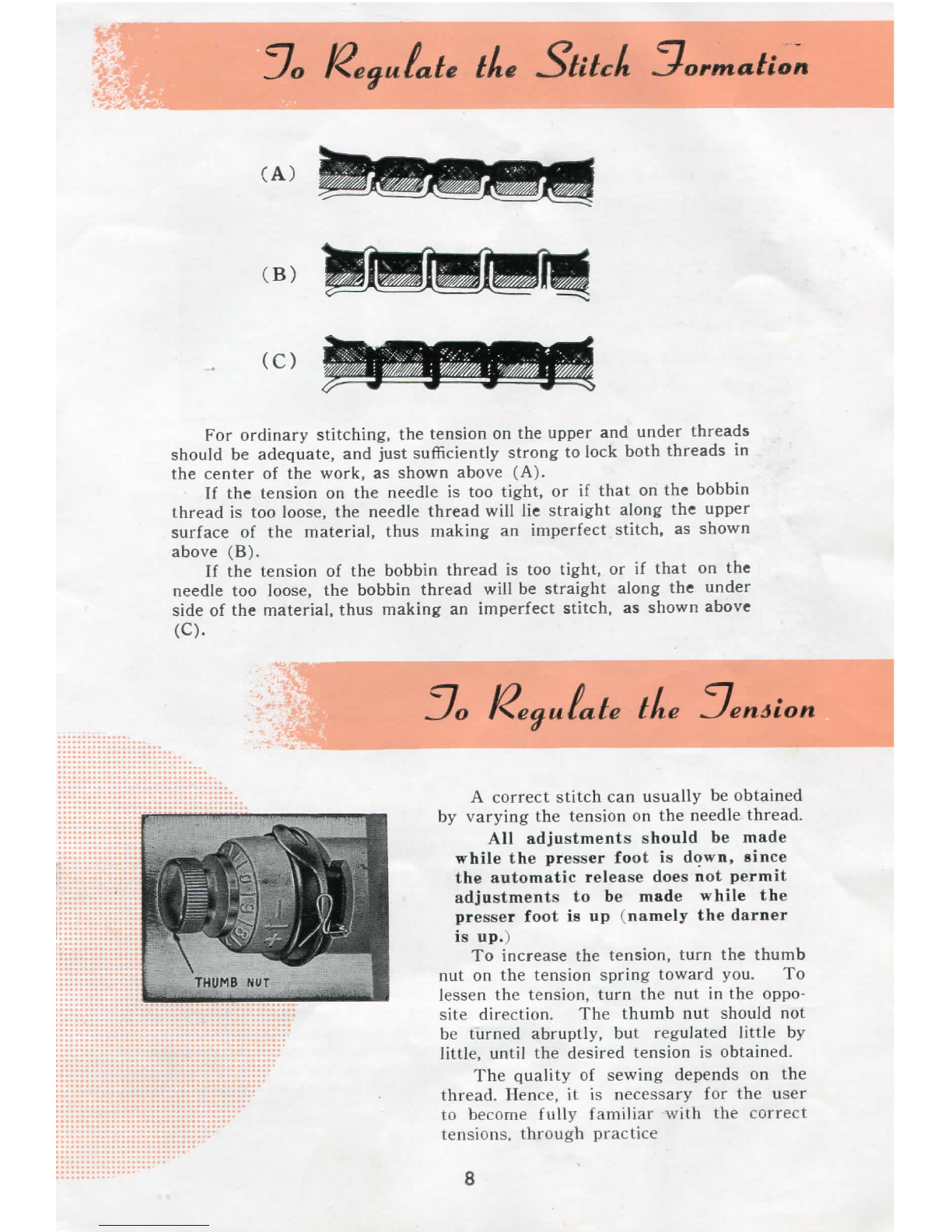

IMPORTANT

NOTICE

Never operate the

machine with-oui

material under the

presser foot. If this

is not strictly ad-

hered to, your ma-

chine will lock, and

cannot be operated

until the thread is

cleaned out of the