TPP

INSTRUCTION MANUAL

Page 4 Date rev. 28/05/13

Rev. 07

2. INTRODUCTION

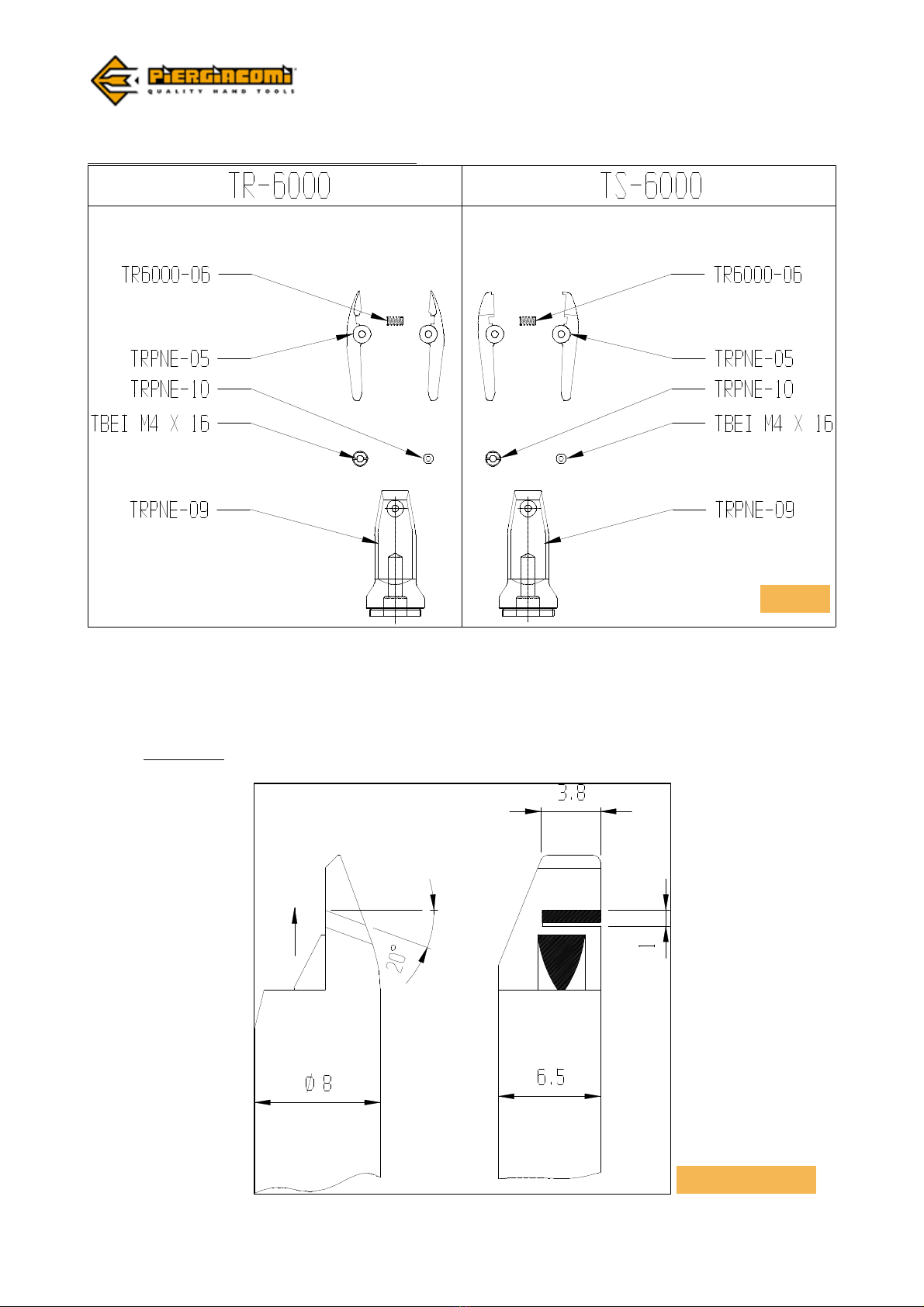

2.1 TR-6000 – TR-6000-V

Piergiacomi has become aware of the enormous problems associated with staff that, during the working

day, carry out multiple cutting operations, in any sector, from electronics to the plastic or rubber industry.

We have studied the problem and obtained the TR-6000, thanks to our vast experience in industry tools,

the ideal lightweight tool and with reduced costs.

Furthermore, it’s available the TR-6000-V model too, which has a flush front 60° angled cut, in order to

have the access in difficult points.

This is the basis of our philosophy and our product has been designed to meet both performance and

safety requirements.

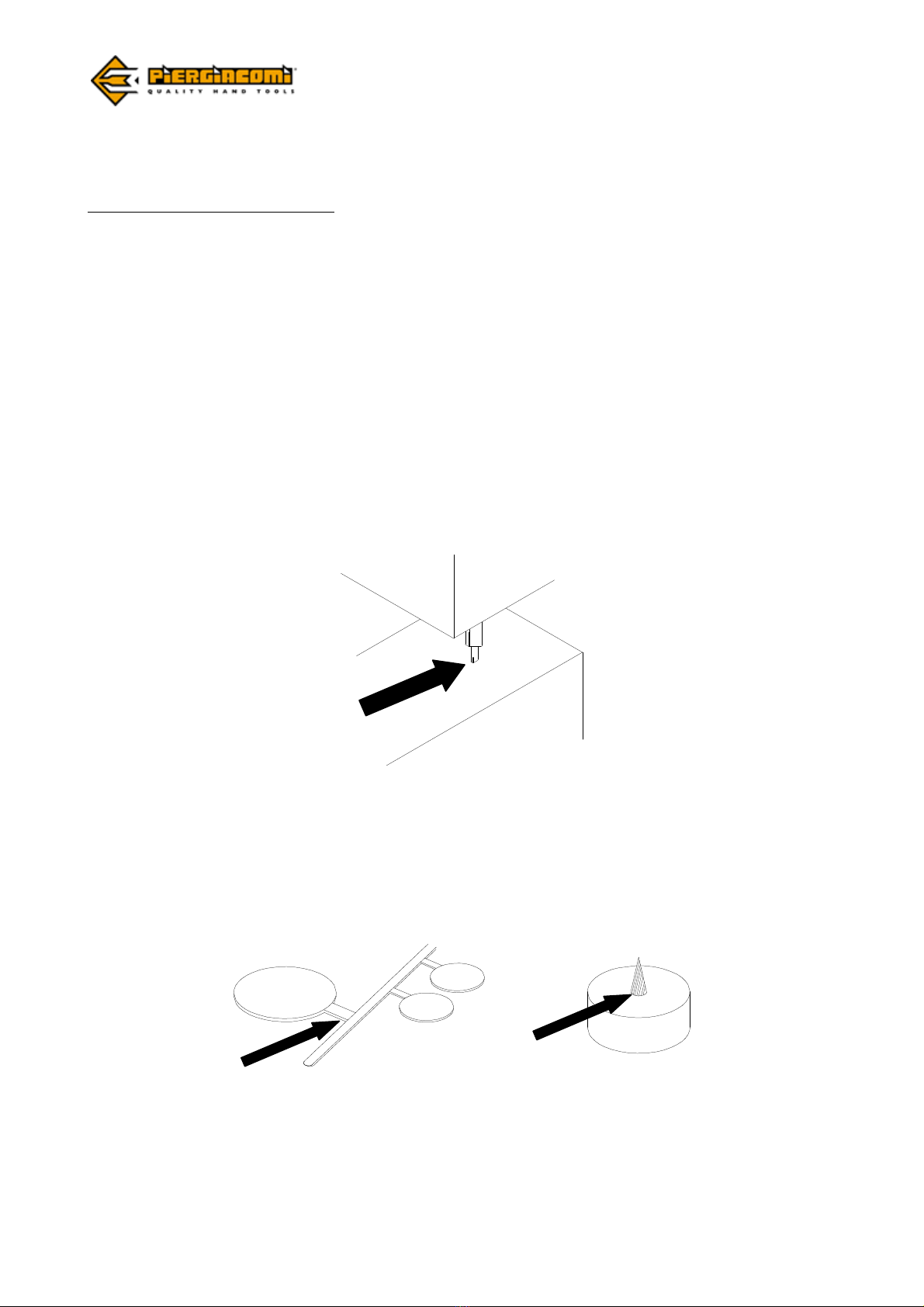

Example: At the end of the component mounting stage of an electronic printed circuit board, the

requirement of cutting multiple leads without causing damage to the components is needed. Therefore

the most qualified solution is to carry out in a fast and efficiently way flush or chamfered cut or a cut at

different heights.

With the wide range of types of tips we enable you to reach normally not much accessible parts as shown

in the diagram.

In the plastic sector, as in that of rubber, cutting the parts without causing damage, when

removing the excess material created by the moulds, is a common problem. –The TR-6000 model

is suitable for cutting small diameters of rubbing material. For cutting bigger diameters,

Piergiacomi developed several solutions, like the TPP-TM-6000.