Pioneer PD-M423 User manual

Other Pioneer CD Player manuals

Pioneer

Pioneer CLD-980 User manual

Pioneer

Pioneer PD-31 User manual

Pioneer

Pioneer PD-F807 User manual

Pioneer

Pioneer PDF904 User manual

Pioneer

Pioneer PD-C5 User manual

Pioneer

Pioneer DEH-P4350 ES User manual

Pioneer

Pioneer PD-M601 User manual

Pioneer

Pioneer CLD-S315 User manual

Pioneer

Pioneer CRT2416 User manual

Pioneer

Pioneer CDX-M2086ZBM User manual

Pioneer

Pioneer DEH-P430/X1N/UC User manual

Pioneer

Pioneer YPM-2296ZF User manual

Pioneer

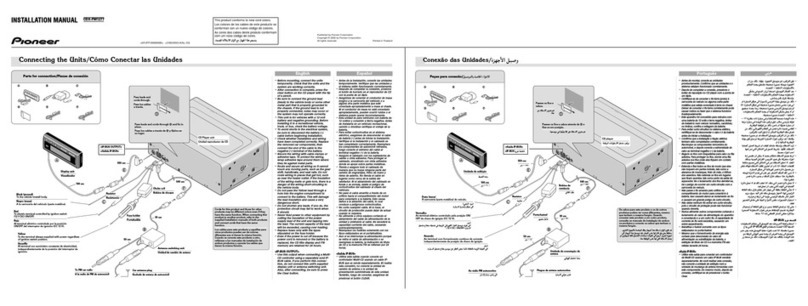

Pioneer CDX-FM1277 User manual

Pioneer

Pioneer DEH-1650XU/ES User manual

Pioneer

Pioneer PD-F1039 User manual

Pioneer

Pioneer VP-1000 User manual

Pioneer

Pioneer CDX-FM1277 User manual

Pioneer

Pioneer DEH-P3500 User manual

Pioneer

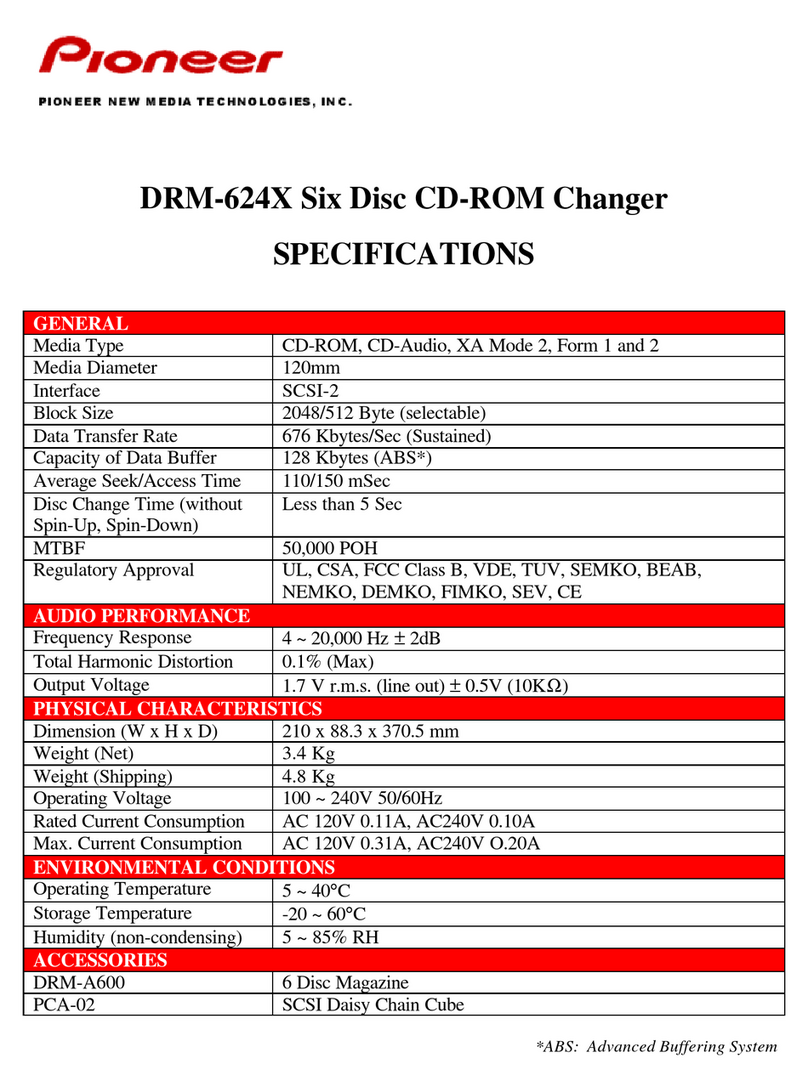

Pioneer DRM-624X User manual

Pioneer

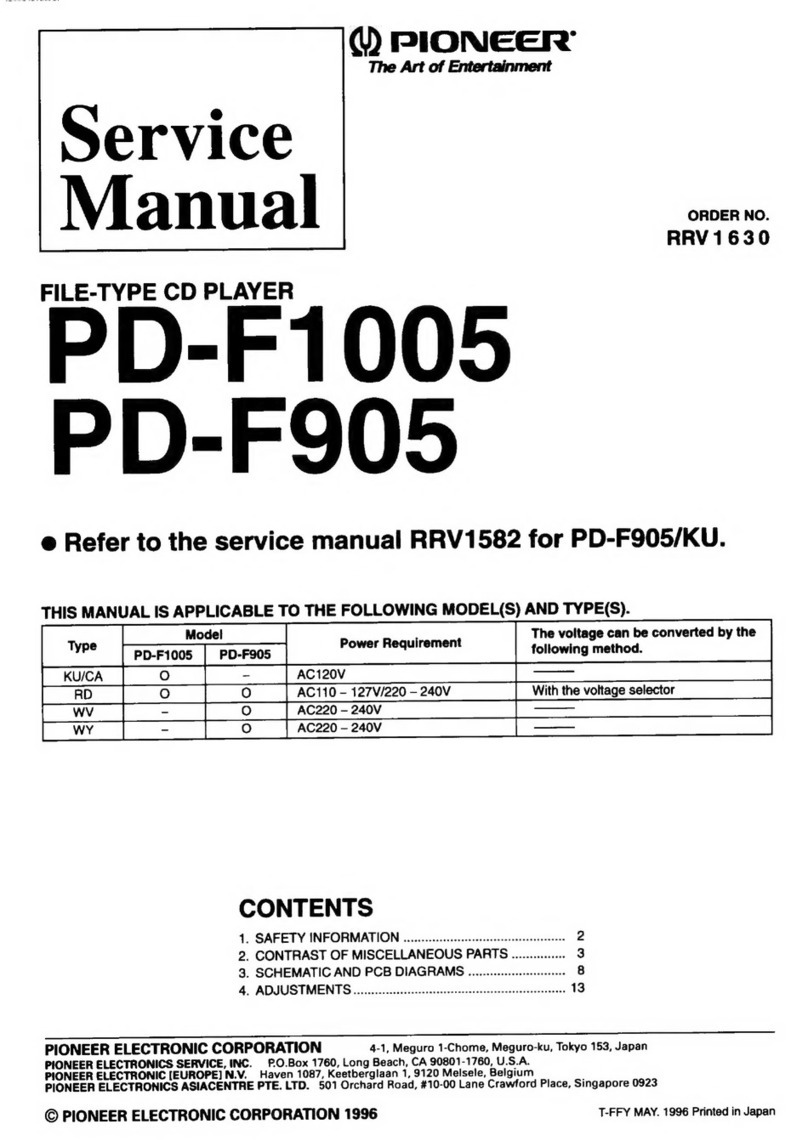

Pioneer PD-F1005 User manual