9

I-BEAM RF POWER SUPPLY MANUAL Chapter 1: Getting Started

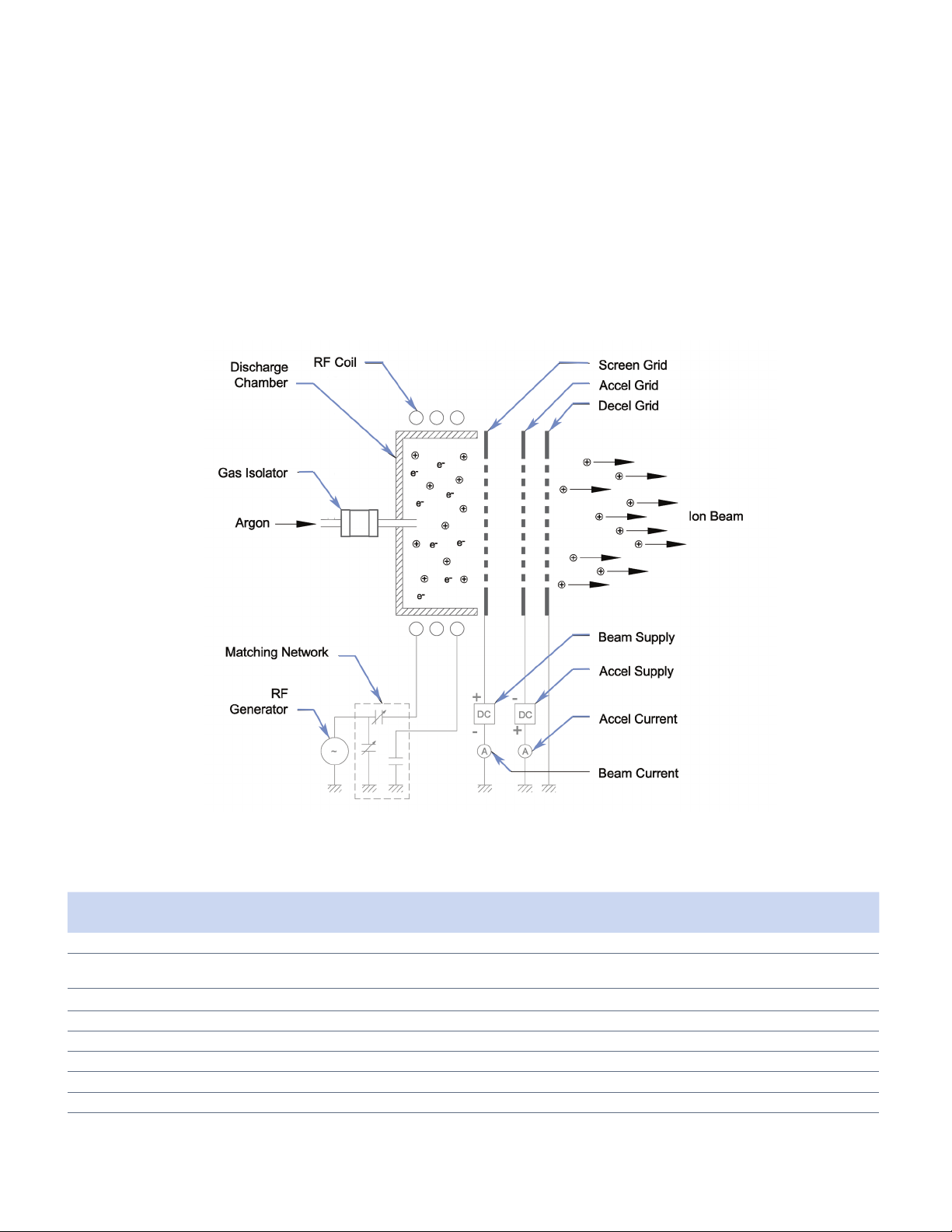

The grids, which control the ion optics, will come in

dierent shapes, sizes and materials. They can be

at (i.e. graphite) or dished (i.e. molybdenum) to

promote beam shape and trajectories. The inner

most grid is called the screen grid (biased positive)

and the middle grid is called the accelerator (biased

negative). Most grid assemblies will have 3 grids

where the decelerator will act as a shield to the other

two grids and capture process material coming back

to the source. Additional information about the grid

operation and design can be found in the Ion Beam RF

Sources Manual.

A neutralizer is placed downstream from the source

where it emits electrons to balance the number

of positive ions which leave the source. The RFN

operates in a similar fashion to the source as it

requires process gas, has an RF antenna and its own

matching network. Please refer to its manual for a

detailed description of its operation and additional

information.

The RFN needs to be placed so that its electrons can

couple (or “see”) the ion beam. It is very important

that these electrons have a close (about 150 mm),

unobstructed path to the beam to ensure stable,

noise free operation. The RFN should also be located

away from strong magnets or shielded from magnetic

elds using 400 series stainless steel. A common

challenge will be to protect the RFN from process

material that can coat its keeper - but allow for

electrons to couple.

Electrons from the neutralizer do not recombine

with source ions, rather they provide space-charge-

neutralization for the downstream plasma. Under

normal operation, the neutralizer will emit between

125% to 200% of the measured beam current. In this

fashion substrates or targets downstream will not

suer damage due to arcing or surface charging.

Typical grids before assembly.

Place the RFN in close proximity to the ion beam.

The RFN will emit more electrons than ions from

the source.