CONTENTS

USING THE PRODUCT SAFELY ···························Ⅰ-Ⅳ

1. GETTING STARTED ...................................................1

1-1. PFR-100 Series Overview...............................................1

1-1-1. Series lineup .....................................................................................1

1-1-2. Main Features...................................................................................1

1-1-3. Accessories.......................................................................................2

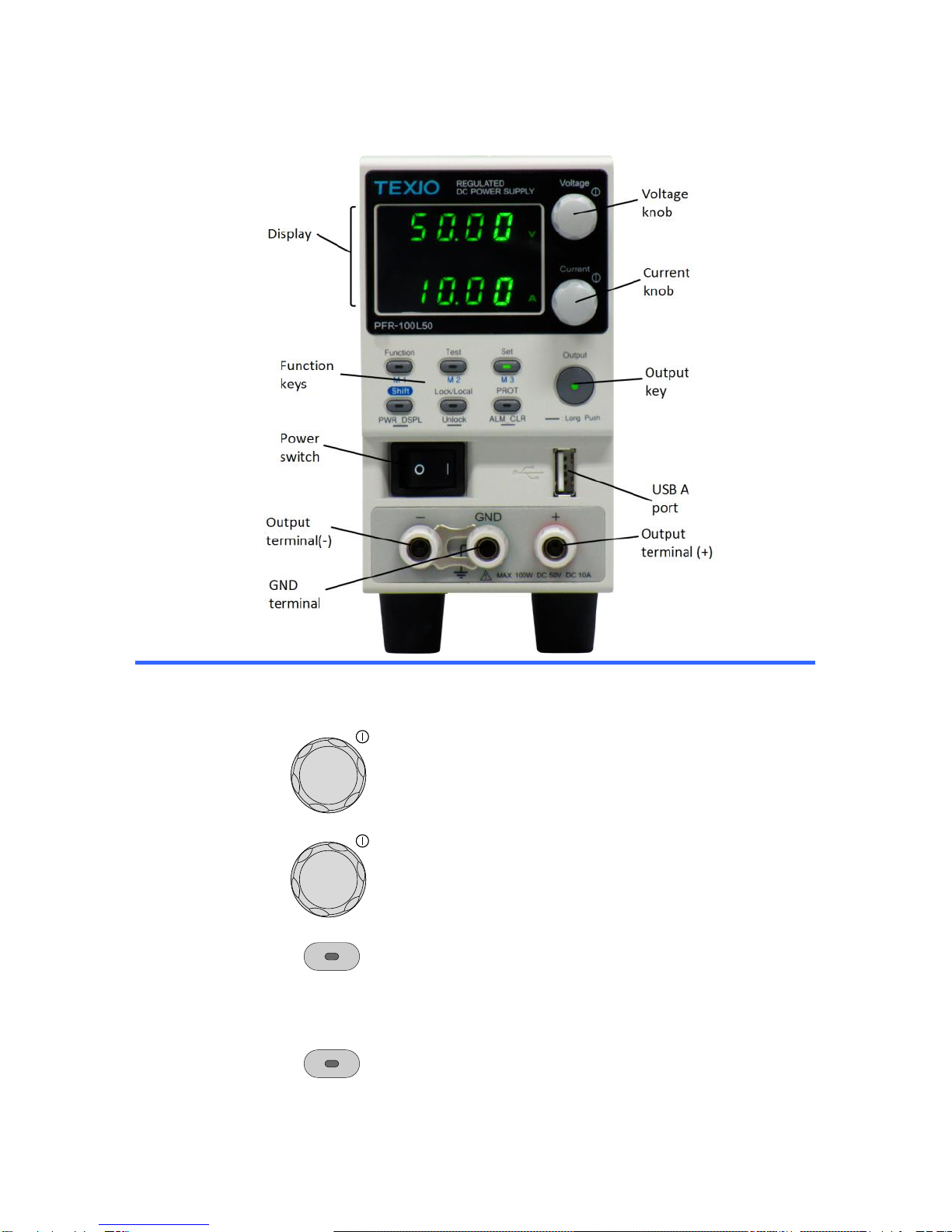

1-2. Appearance....................................................................3

1-2-1. Front Panel........................................................................................3

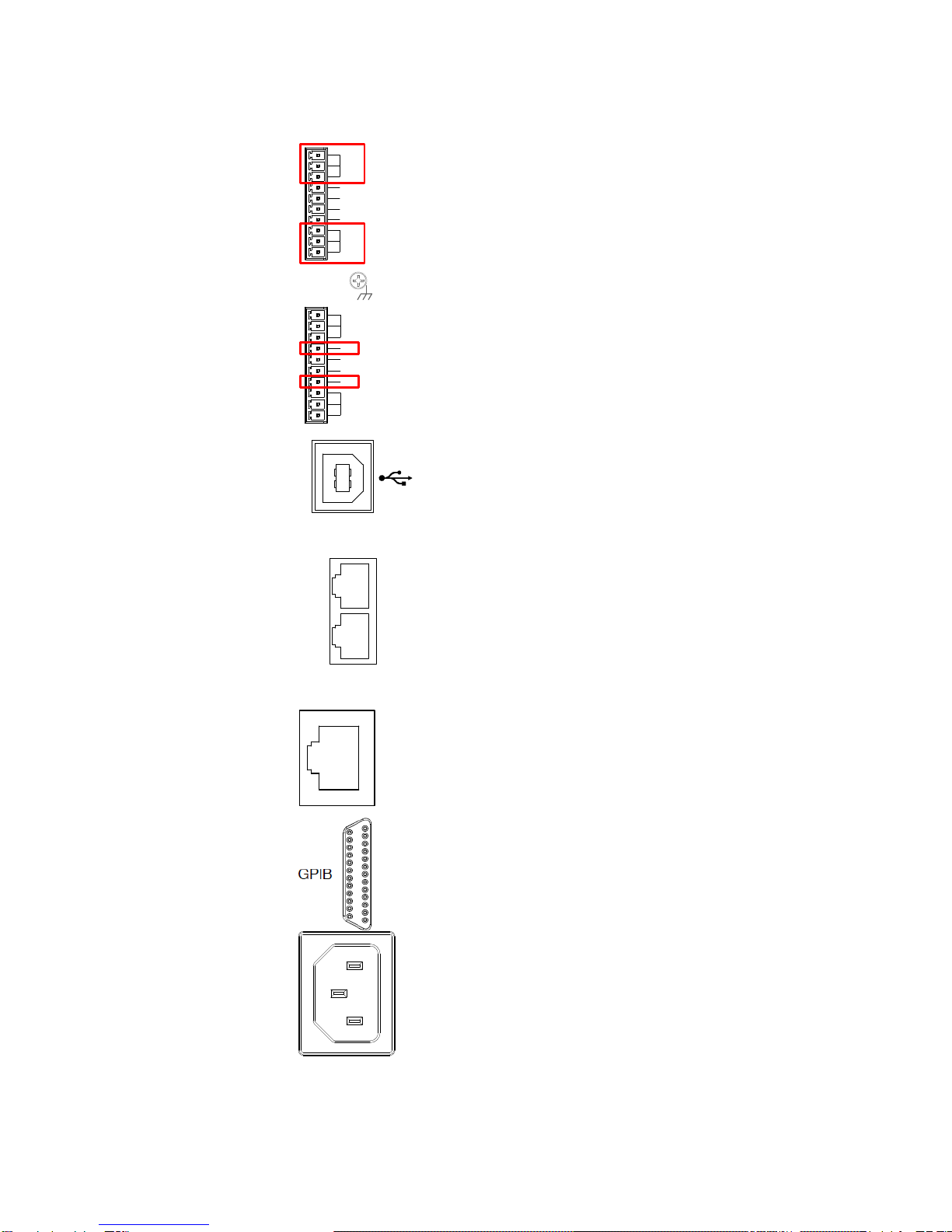

1-2-2. Rear Panel........................................................................................5

1-3. Theory of Operation .......................................................7

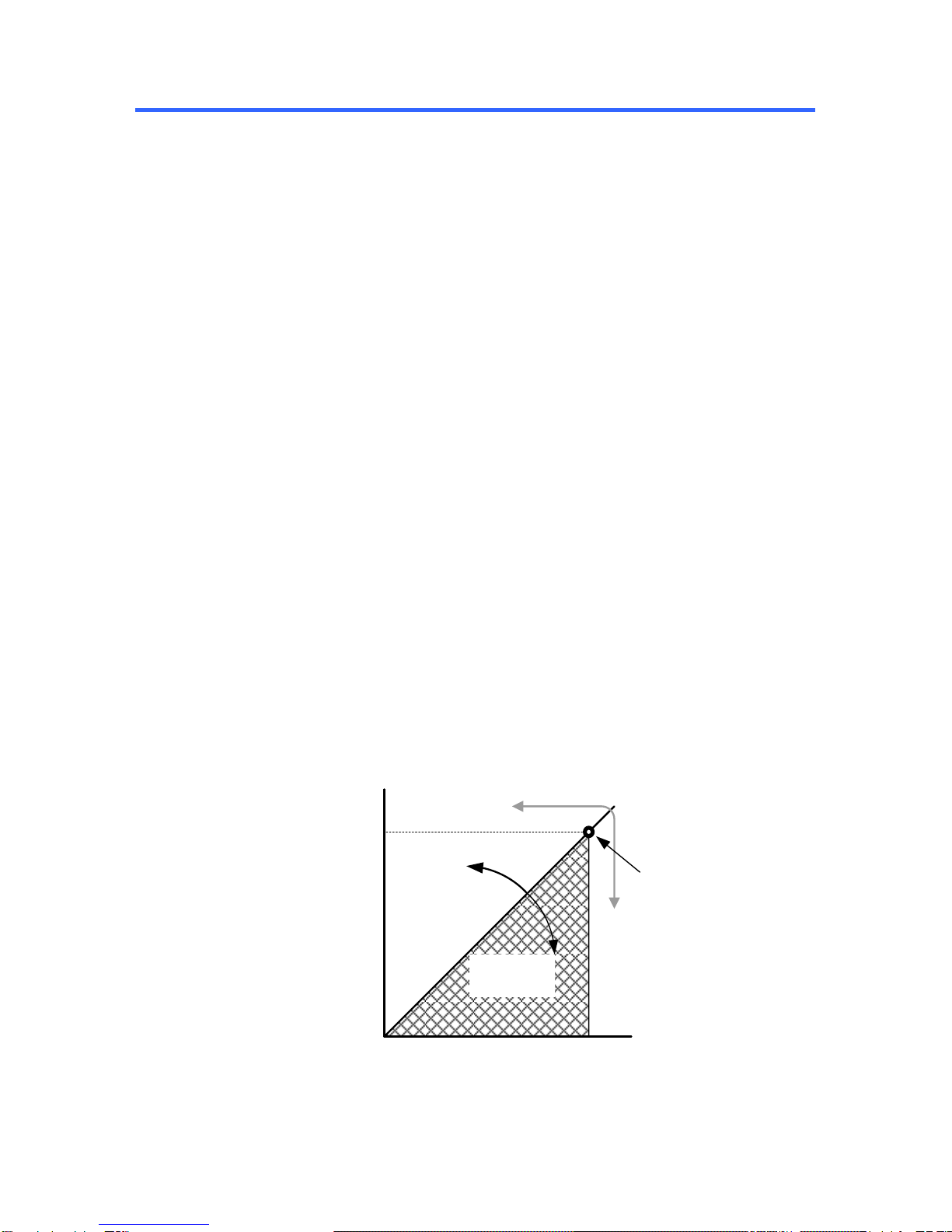

1-3-1. Operating Area Description...............................................................7

1-3-2. CC and CV Mode..............................................................................8

1-3-3. Slew Rate..........................................................................................9

1-3-4. Bleeder Control.................................................................................9

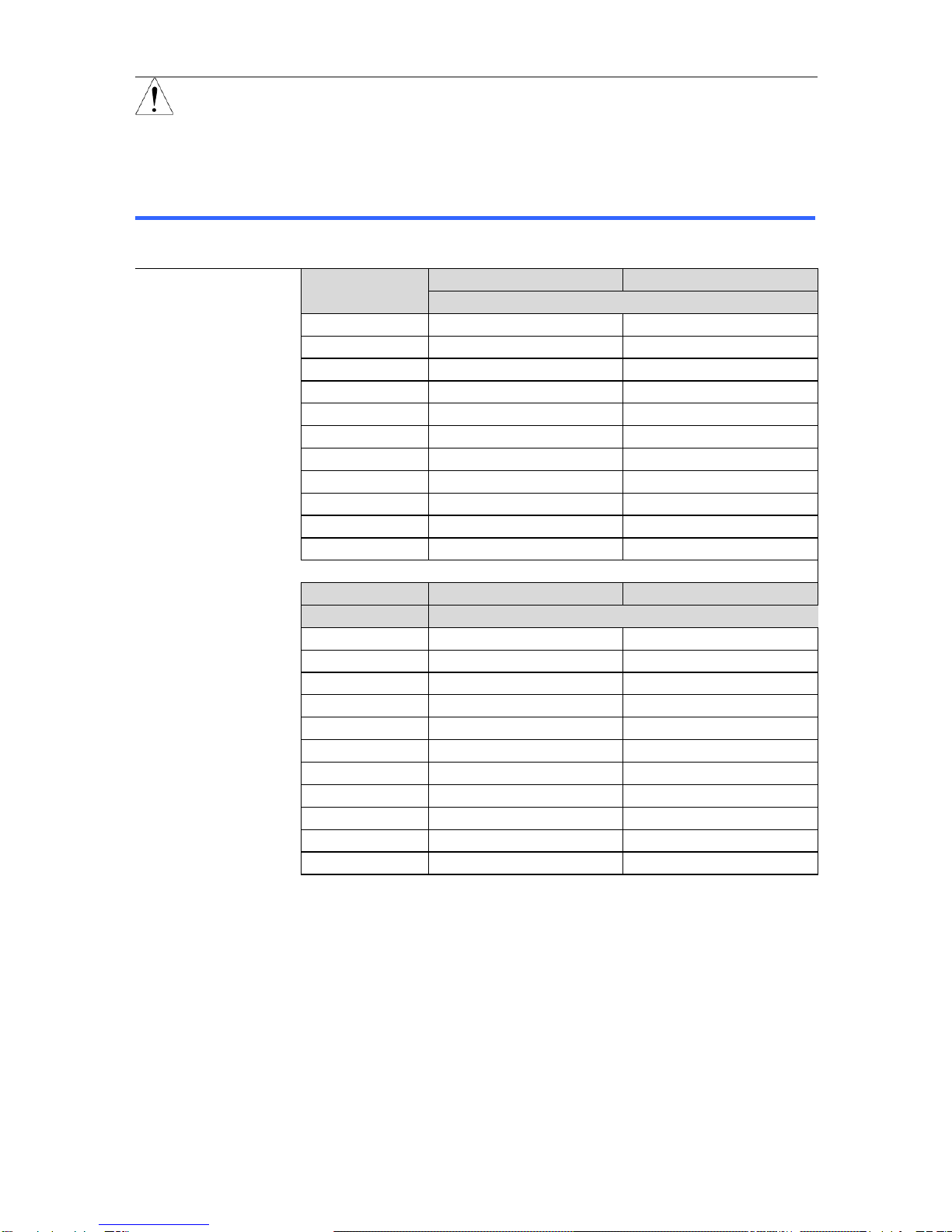

1-3-5. Sink Current Table ..........................................................................10

1-3-6. Alarms.............................................................................................11

1-3-7. Considerations................................................................................11

1-3-8. Grounding .......................................................................................13

2. OPERATION.............................................................15

2-1. Set Up ......................................................................... 15

2-1-1. Power up.........................................................................................15

2-1-2. Wire Gauge Considerations............................................................15

2-1-3. The Rear Panel Output Terminal ....................................................16

2-1-4. The Front Panel Output Terminal....................................................17

2-1-5. Using the Output Terminal Cover....................................................18

2-1-6. Using the Rack Mount Kit................................................................19

2-1-7. How to Use the Instrument..............................................................19

2-1-8. Reset to Factory Default Settings....................................................20

2-1-9. View System Version and Build Date..............................................21

2-2. Basic Operation............................................................ 23

2-2-1. Setting OVP/OCP/UVL Levels ........................................................23

2-2-2. Set to CV Mode...............................................................................25

2-2-3. Set to CC Mode...............................................................................27

2-2-4. Display Modes.................................................................................29

2-2-5. Panel Lock ......................................................................................29

2-2-6. Preset Memory................................................................................30

2-2-7. Remote Sensing..............................................................................31

2-3. Test Script.................................................................... 33

2-3-1. Test Script File Format....................................................................33

2-3-2. Test Script Settings.........................................................................33

2-3-3. Setting the Test Script.....................................................................33

2-3-4. Load Test Script from USB drive.....................................................34

2-3-5. Run Test Script ...............................................................................35

2-3-6. Export Test Script to USB ...............................................................36

2-3-7. Remove Test Script.........................................................................37

2-3-8. Checking the Available Memory......................................................37