Statement of warranty:

PlasmaPart Limited hereby warrants to the original purchaser that new PlasmaPart

machines sold are free from material defects and defective workmanship, should any failure

arise within a period of three (3) years from the invoice date and the machine has been

treated in accordance with the guidelines stated in this manual, PlasmaPart Limited will

collect the machine, return it to working condition or replace it at our discretion and re-

deliver it to you as quickly a possible –typically within 48 hours.

This warranty is in lieu of any warranty of merchantability or fitness for a particular purpose.

Warranty period: 3 years parts and labour on power source

1 year parts and labour on torch

This warranty is conditional on you retaining the original packaging or being able to pack the

machine so it can be transported safely by our delivery partner. If the machine is damaged

in transit from you to us in the event of a warranty claim, you may be charged some of the

repair costs if the machine has not been packaged adequately.

The warranty explicitly excludes:

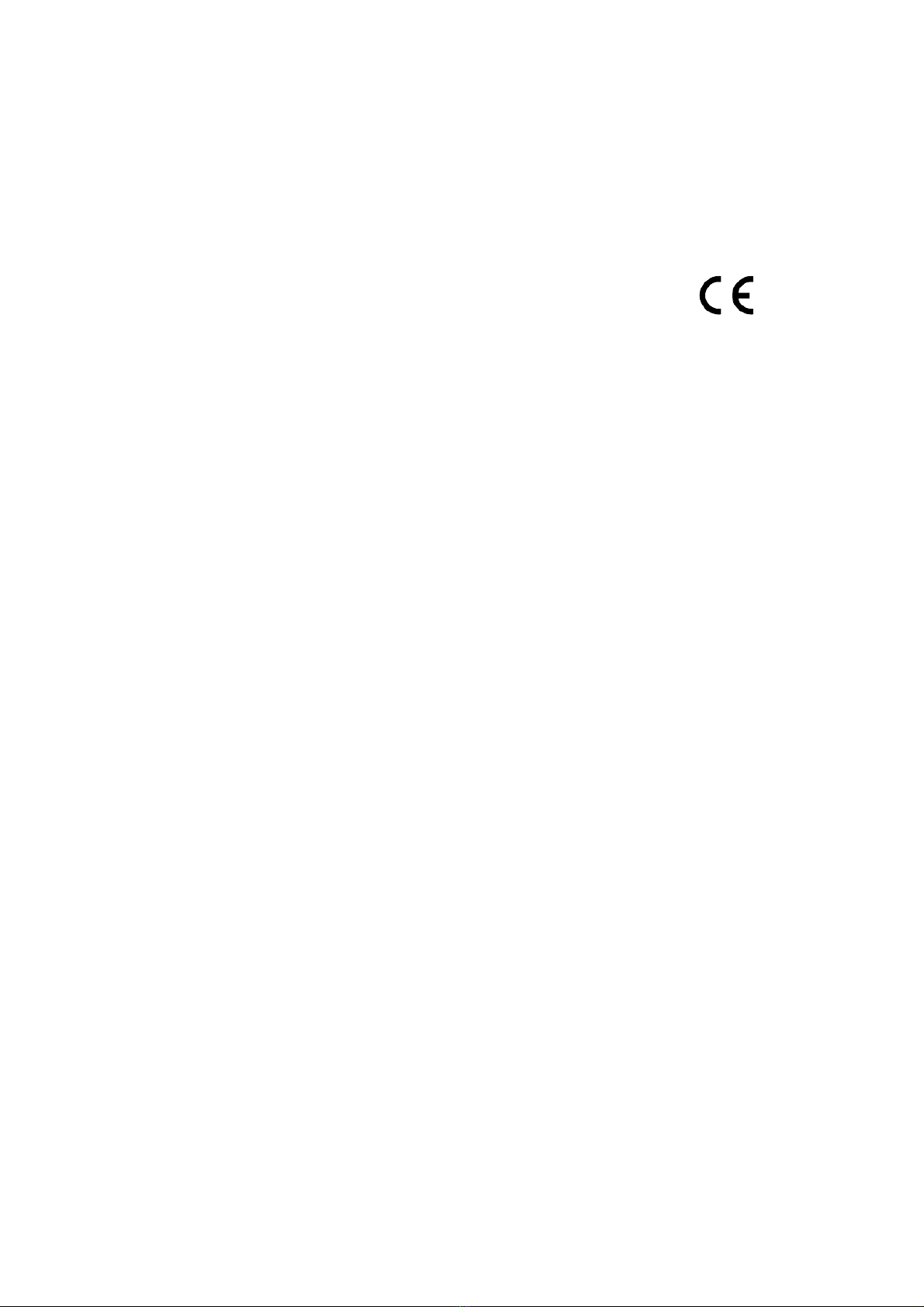

Consumables, electrodes, nozzles, swirl rings, o-rings, fuses and filters

Equipment that has been modified, improperly used or installed, misused or

improperly operated according to the guidelines in this manual

Limitation of liability:

We shall not be liable or responsible for any injury, illness, accident, misfortune, loss of

profit, loss of earnings, loss of life however caused as a result of buying and/or using or

misusing the product(s). In no event shall PlasmaPart be liable or responsible to you or any

third party for any personal, mental, physical injury or illness, consequential, direct, indirect,

special or contingent damages arising from the use, misuse or failure of the product(s) sold

or advice given. Our cumulative liability on account of a claimed defect in any product

supplied by PlasmaPart or any damages of whatsoever type caused by the use or misuse of

the products(s) shall in no event exceed the purchase price paid by you.