06 07

WARNING: Prevent Electrocuon.

Do not connect any auxiliary components

(for example cable, addional speakers,

headphones, addional audio/video

components, etc.) to system

: Risk of Electrical Shock.

Do not service this product yourself as

opening or removing audio covers may

expose you to dangerous voltage or

other risk of injury. Refer all servicing to

qualied service personnel

: Risk of Electrical Shock. When

the power supply connecons or power

supply cord(s) are damaged; if water is

entering the audio / video compartment

or any electrical equipment compartment

area; if the protecve shields or barriers

are showing signs of deterioraon; or if

there are signs of other potenal damage

to the unit, turn o the unit and refer the

servicing to a qualied service personnel

: This unit should be subject to

periodic roune maintenance (for example,

once every 3 months) to make sure that

the unit is operang properly

: Do not operate audio video

controls while inside the spa

INSTALLATION of the spa for other than a

residenal dwelling will result in voiding the

manufacturer’s warranty

: Do not bring any object into

the spa that could damage the spa shell

: Never insert any object into

any opening

WARNING: Do not sit on the spa cover or

place objects on it

: Remove any water or debris

that may collect on the spa cover

WARNING: Do not use the spa

immediately aer strenuous exercise

WARNING: If you feel pain or dizziness at

any me while using the spa, disconnue

use and contact a physician

WARNING: To reduce risk of injury it is

especially important that persons with pre-

exisng health condions or problems such

as obesity, heart disease, high or low blood

pressure, circulatory problems, pregnancy

or diabetes to consult their doctor before

using the spa

WARNING: Observe reasonable me

limits when using the spa. Long exposures

at high temperatures can cause high body

temperatures. Symptoms may include

dizziness, nausea, fainng, drowsiness, and

reduced awareness. These eects could

possibly result in drowning

WARNING: The spa jets produce a stream

of water with relavely high pressure

Prolonged exposure of localized area of the

body may cause bruises to the skin

: The include warning sign

must be posted where all users of the spa

can see and read it

WARNING: To avoid risk of drowning. The

Spa cover should be in place and properly

latched when spa is not in use

: Read and understand the

warnings on the spa cover

: Proper water chemistry is

necessary to maintain the water and prevent

possible damage to spa components

IMPORTANT - Do not use a knife to remove

the wrapping.

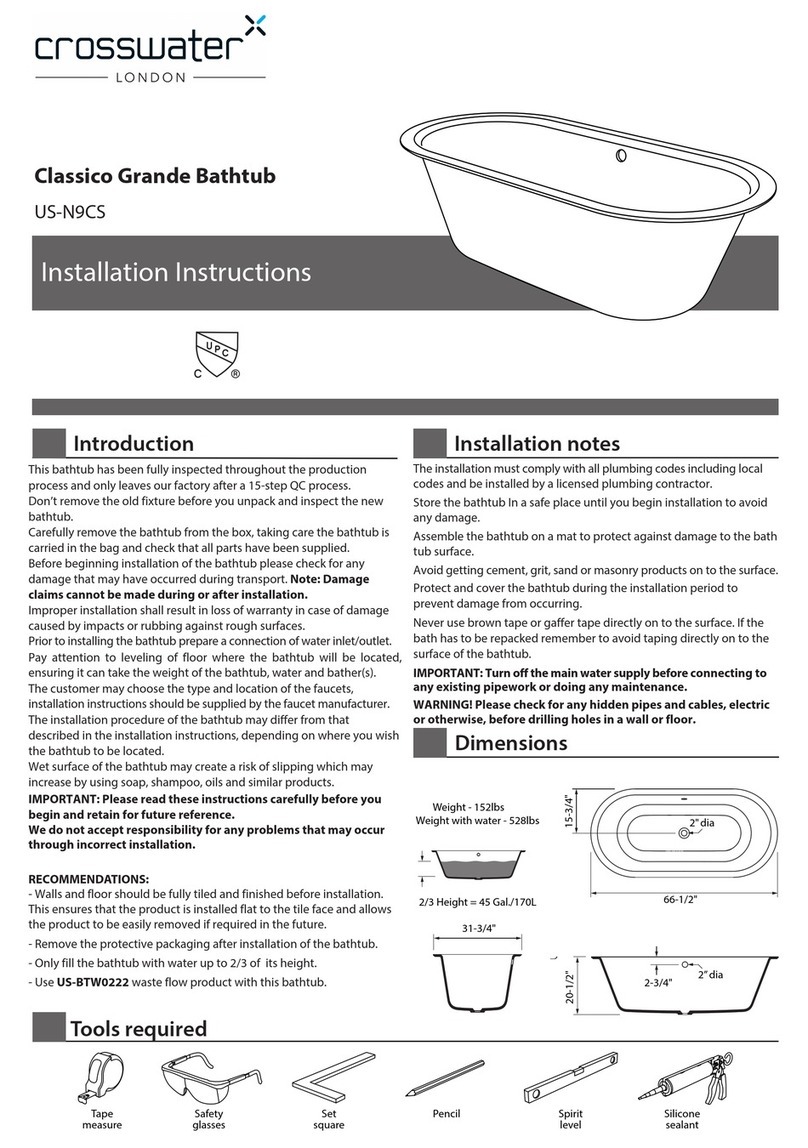

This shower has been factory ed with a quality

whirlpool system. Once ed the whole system

has then been water & electrically tested, quality

inspected and then wrapped to ensure that it

arrives with you in perfect working order.

The quality of this nished product is now in your

hands. Please read all the instrucons overleaf

before commencing installaon. Should you have

any diculty then ring our Technical Support

Engineer on 01246 559071 9am-5pm.

It is the responsibility of the contractor/purchaser

to ensure that this shower is installed only by a

qualied Plumber & a qualied Electrician.

All electrical connecons must comply with the

current edion of I.E.E.

Regulaons. Aer connecon the appropriate

compleon cercate must be presented to the

end user in accordance with I.E.E. Regulaons.

WARNING - If damage is caused to the system

due to mishandling or incorrect installaon,

Superior Spas LTD reserve the right to charge

for any repair work needed! Our Callout charge

is £85.00 inc VAT and will be charged to the

customer for all callouts whether the fault lies with

the customer or the installers.

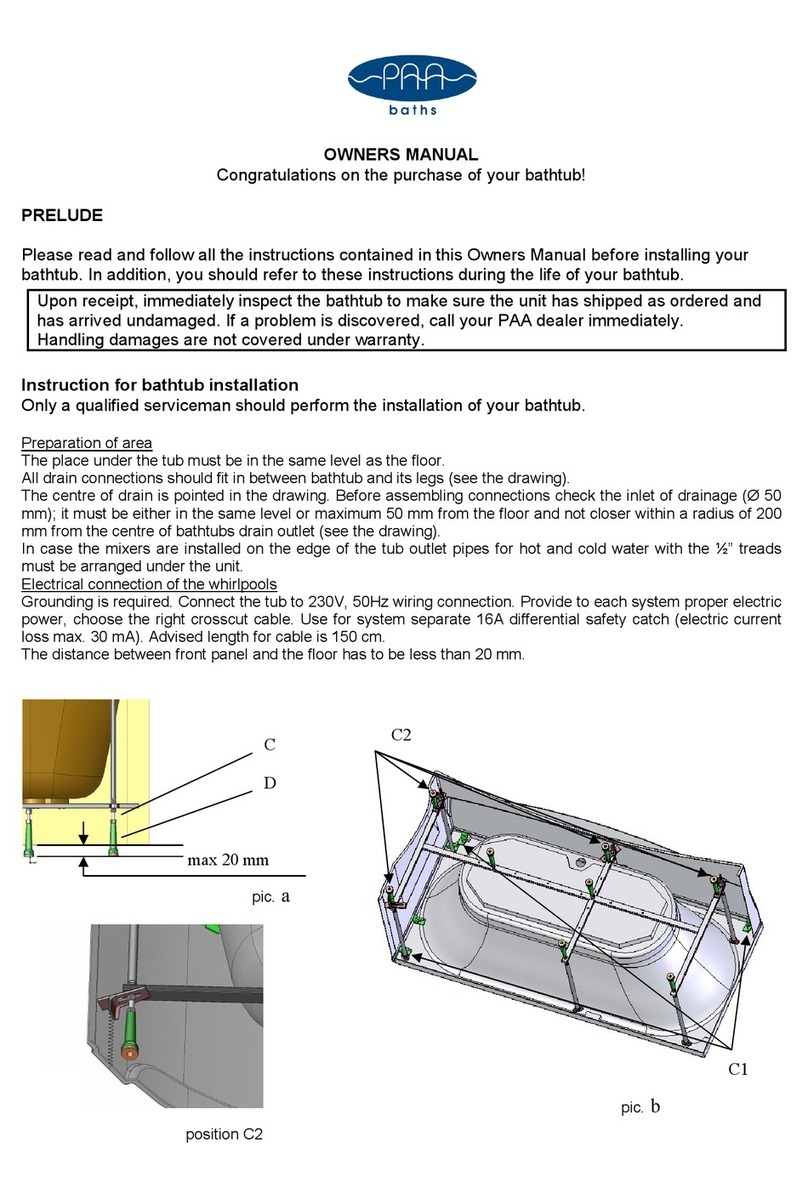

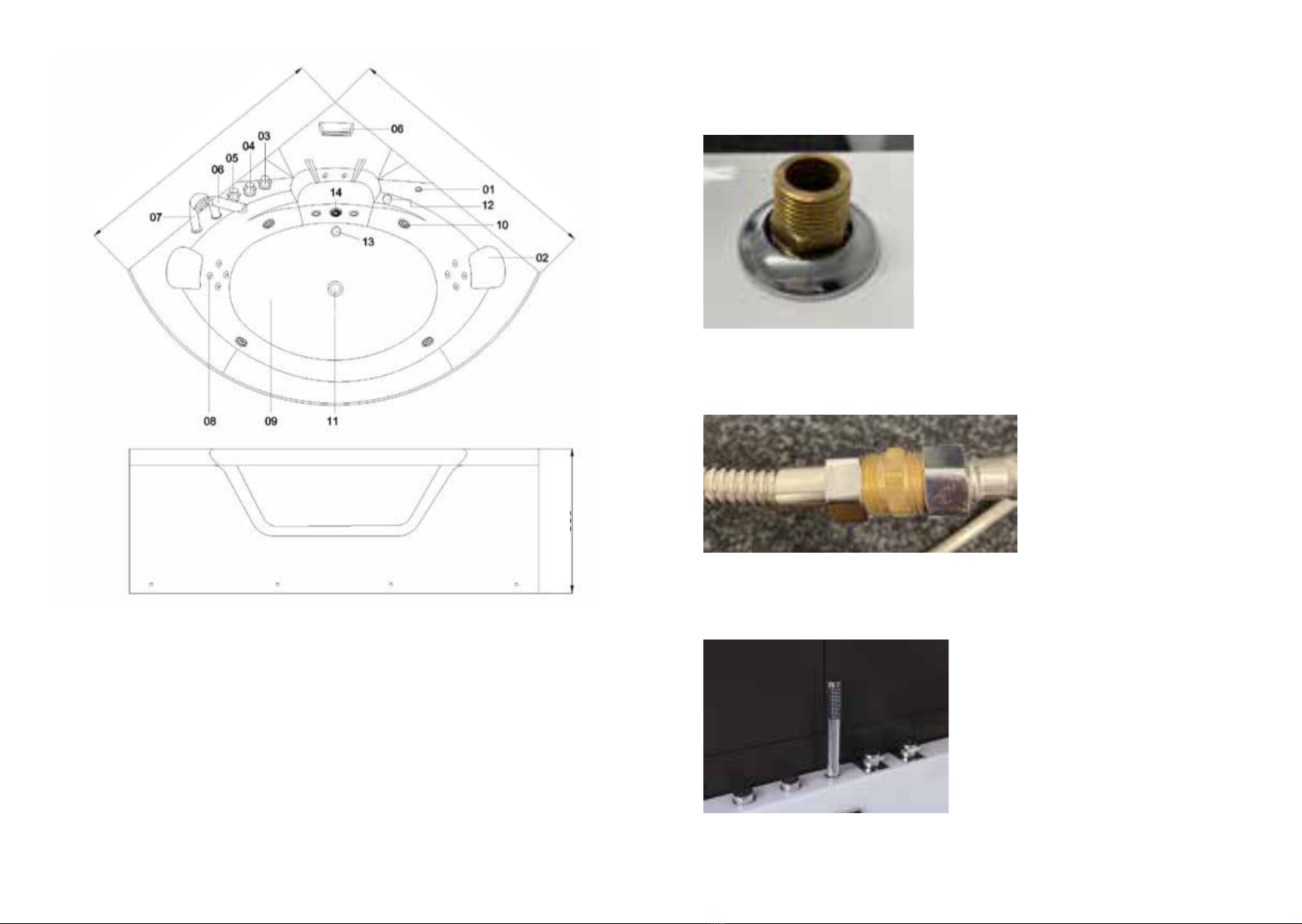

Plumbers Instrucons

This whirlpool system has been ed to this

shower so as to allow as litle water as possible

to remain in the pipework aer use. With some

showers (especially corner showers) our best t

policy can occasionally mean a pump posion or

awkwardly placed pipework which will make life

dicult for the installer and increase the normal

installaon me.

Our policy on water retenon is, that is is beer

for the installer to “suer” for a couple of hours,

than for the end-user to suer for years - If you

are one of the few installers to “suer”, please

accept our apologies.

The quality of this nished product is now in your

hands. If you would like to discuss the opons

available, please ring our Technical Support

Engineer on:

01246 559071

• DO NOT li or manoeuvre the shower by the

whirlpool pipework.

• DO NOT remove the protecve tape from

the controls on the rim of the shower unl all

plastering and groung has been completed.

• Grout dust has been known to cement the

• Aircontrol solid

• DO NOT remove any electrical es on the

pipework - they are there for a purpose.

• DO NOT allow the electrician to install the

E.L.C.B. under the shower - it makes it awkward

for the customer to carry out monthly tesng.

• DO NOT allow anyone to dry run the pump.

i.e.do not run the pump without water in the

system. Water acts as a coolant for the pump

impellor and casing without which costly

damage will occur

• ACCESS must be allowed to remove the pump

and control box

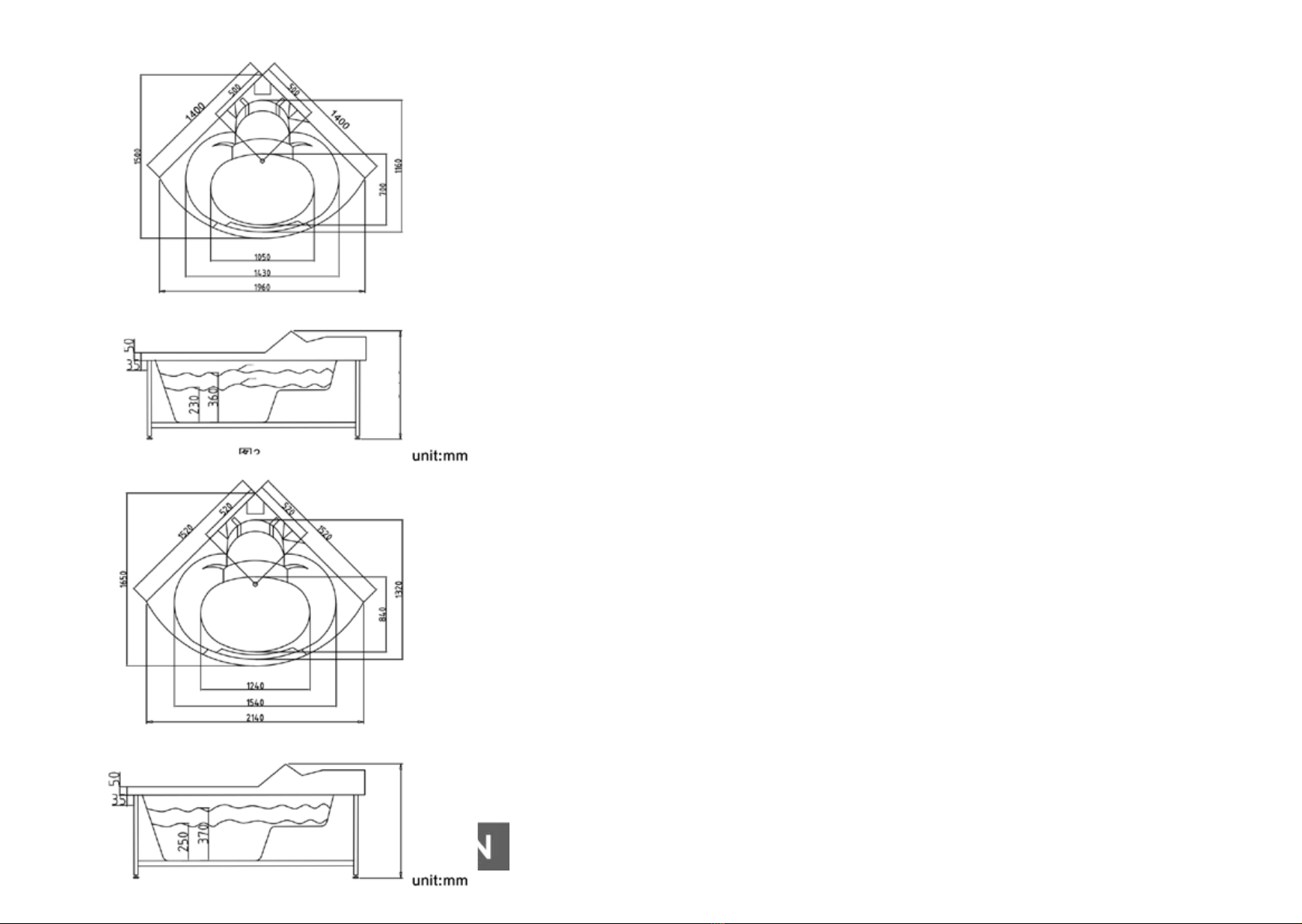

• Assemble the shower legs etc as per the

manufacturers instrucons taking care if

the shower has to be turned upside down.

Occasionally we will temporarily t the legs to

the shower when ng the whirlpool system. If

the legs are subsequently le on the shower it

is sll the plumbers responsibility to check that

all screws and brackets are in place

• Fit and adjust to correct height the pump

bracket support leg

• Adjust feet to the required height for the

shower panel and slide the shower into

posion.

• Set the shower level and pret the shower

into the desired posion. Check that the pump

is within the connes of the shower. If the

pump exceeds the connes of the shower

it will be necessary to chase out the wall to

accommodate the pump. This should be done

before the shower is nally ed

• Ensure that all hot water pipes are clear of

the whirlpool pipework - If necessary remove

shower and re-make the hot water pipes

keeping the blow torch away from the shower

and whirlpool pipework. (Hepworth) ngs

could be used to good advantage.)

• Connect the 8mm OD nylon pipe between the

pump and the black drain ng on the sucon

elbow (Check connecons if already ed)

• When the shower is level in the required

posion, and before nal xing takes place,

temporarily connect the waste and water feeds,

ll the shower with warm water to the level of

the overow and operate the whirlpool system

under pressure for a period of twenty minutes

• During this me all joints should be checked

to ensure that they have not been damaged or

weakened in transit. Leave the shower standing

with water in it for a further 20 minutes and

recheck the joints. Carry out procedures detailed

in the commissioning checklist opposite.