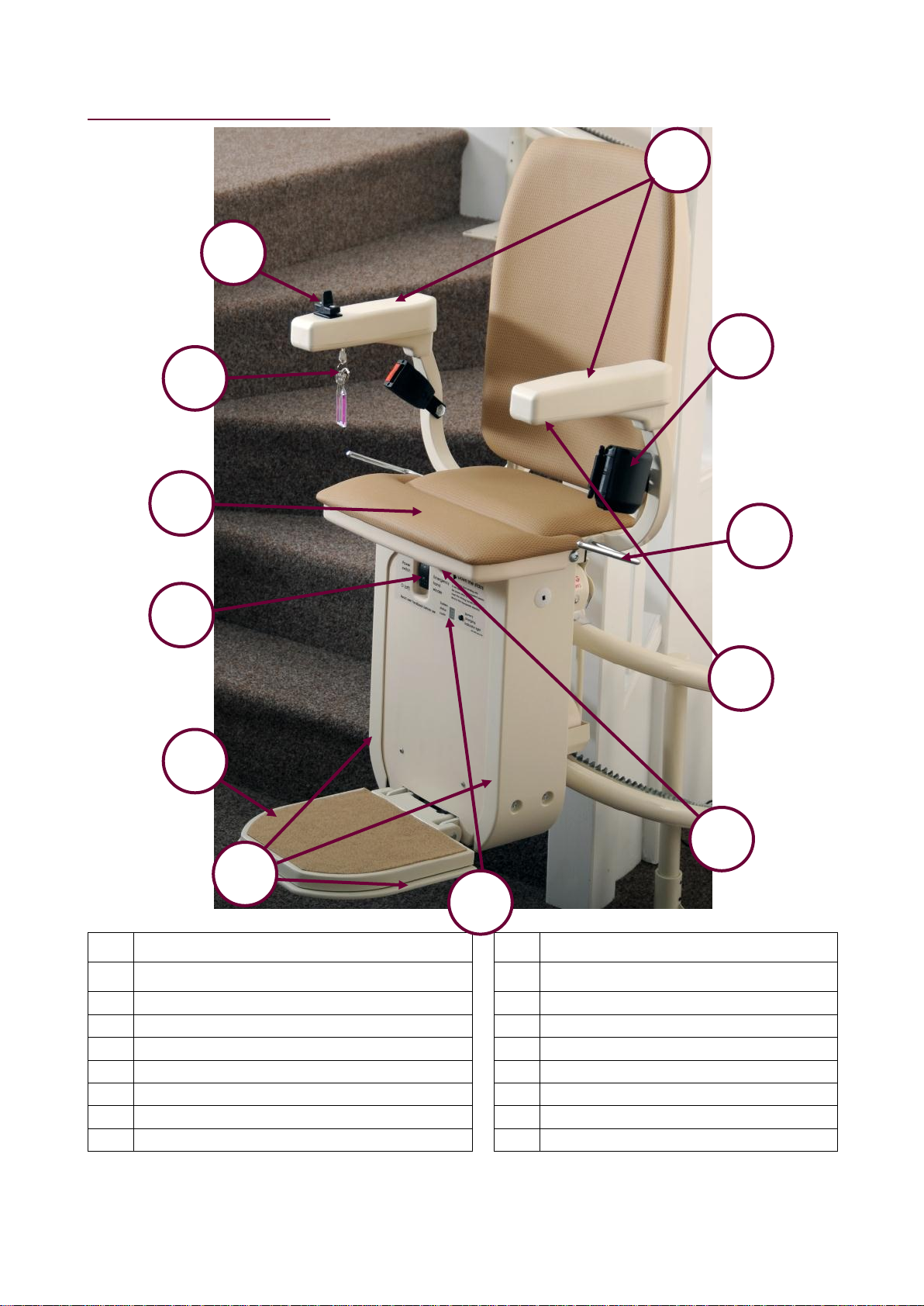

Stairlift Discription ………………………………………………………………………

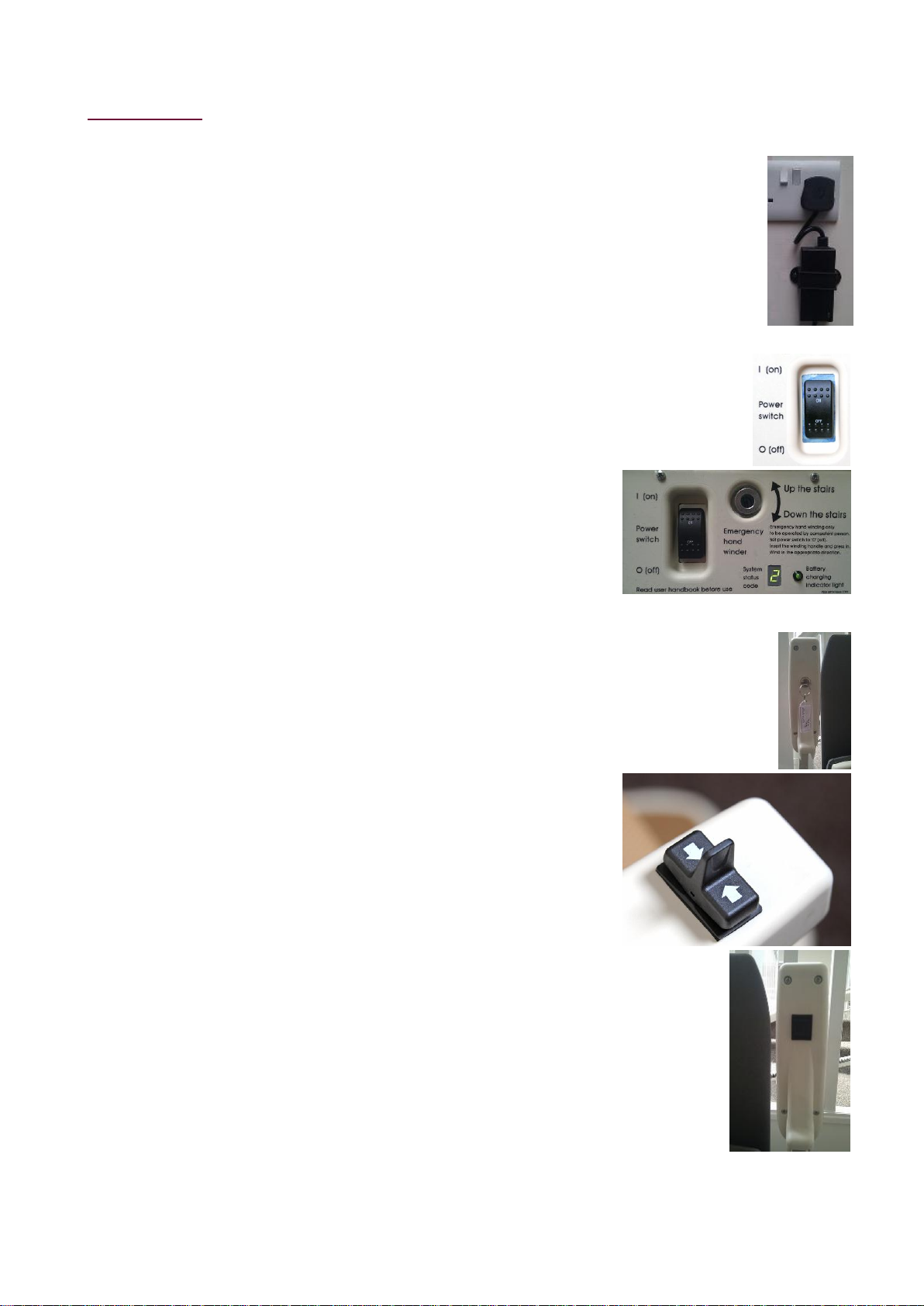

Controls ……………………………………………………………………………….………………………………………………………………..

Swivel Seat ……………………………………………………………….……………………………………………………………………..

Charging Points ………………………..…………………………………………………………………………………………………………….

Remote Controls ………………..…………………………………………………………………………………………………………………….

Kitting List …………………………………………....................................................................

Required Installation Equipment …………………………....................................................

Installing the Stairlift ……………………………………….....................................................

Installation Drawing ………………………………………………………….........................................................................................

Assembling the Rail …………………………………………………....................................................................................................

Fixing the Rail Assembly in Place ………………………………………………………………………………………………………………..

Fitting the Carriage to the Rail ………………………………………………………………..

Fitting the Batterys …………………………………………………………………………………………………………........................

Fitting the Combined End Stops/Charging Ramps …………………………………………………………………………………………..

Charge Circuit ……………………………………………………………………………………………………………………………………...

Intemediate Charge Point …………………………………...........................................................................................................

Fitting the Chair to Carriage ………………………………………………………………………………………………………………..

Chair and Carriage Electrical Connections ……………………………………………………………………………………………………..

Manual Carriage …………………………………………….…………………………………………………………………………….

Powered Footrest Carriage………………………………………………………………………………………...................................

Test Running Stairlift Unladen and Unprogrammed …………………………………………...

Programming Half and Full Speed ………………………………………………………………..

Installing Remote Controls ……………………………………………...........................................................................................................

Test Running the Stairlift Fully Laden and Programmed .……………………………………

Final Checks ……………………………………………….……………………………………

Contract/Installation drawing ……………………………………………….........................................................................................

Electrical, Battery and Operational Tests ……………………………………………………………………………………………………..

Certificate for Test and Examination After Installation …………………………………………………………………………………………..

Instructing the User ……………………………………………………………………………..

Paperwork …………………………………………………………………………………………...

Test Certificate ……………………………………………………………………………………………………………………………………...

User Guide ……………………………………………………………………………………………………………………………………...

Offset Footrest Option ……………………………………………………………………………...

Connection Diagram ……………………………………………………………………………..

Technical Information ……………………………………………………………………………..

Weight limits ……………………………………………………………………………………………………………………………………...

Operating Periods………………………………………………………………………………………………………….......................................

Handwinding the Stairlift …………………………………………………………………………………………………………………………..

Diagnostic codes…………………………………………………………………………………….

Mains Power, Battery Power and Power Cuts ……………………………………………………………………………………………………..

Servicing …………………………………………………………………………………………..