3 of 39pages

2.

Safety

The lift can only be used after you have thoroughly read and understood

these manual. Unauthorized modifications in the lift and its safety devices

are prohibited. PM-Tools shall not be responsible for any damages resulting

from violating of this regulations.

The following hints should be observed:

•

Risk of crushing.

•

Use personal protection equipment.

•

Observe all accident prevention regulations.

•

We recommend to create a 3-meter safety zone around the lift.

•

Make sure that the lift does not obstruct the exit paths. This is especially

important when the vehicle is placed on a lift.

•

Make sure that there are during the lifting and lowering of the lift there

are no dangerous situations in the safety zone. If this happens, stop the

lift immediately and remedy the cause of the dangerous situation.

Dangerous situations can include people or animals staying in the safety

zone of the lift.

•

Make sure there are no objects under the lift when it is raised.

•

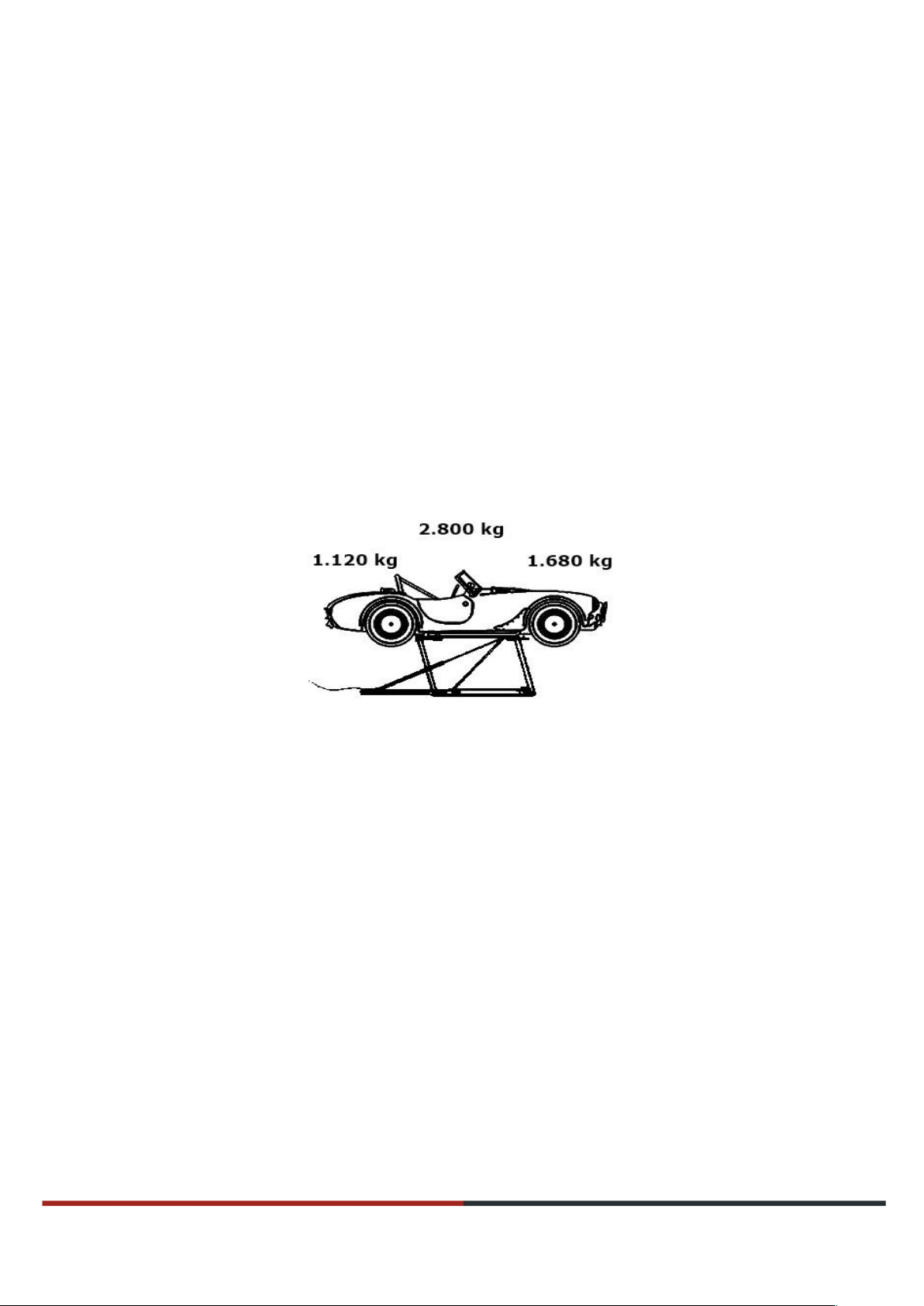

Do not exceed the permissible load capacity. Observe the information

given on the rating plate.

•

Make sure that vehicle weight and load distribution in lifting points

conform to the recommendations given in this user's manual.

•

Make sure that disassembly of the vehicle parts will not cause shifting of

the load/centre of gravity so that the required limits are no longer

observed.

•

Secure the lift in lifted position lifting it only to the next safety catch and

installing the pin lock using a safety pin.

•

Depressurize the lift in case of failure or during maintenance and repair

works. To depressurize the lift, disconnect the air hose from the

connector.

•

Check for leaking hydraulic hoses.

•

Only original spare parts should be used.

pm-tools, Małorolnych 10B, PL-66-400 Gorzów Wielkopolski,www.pmtools.pl