2

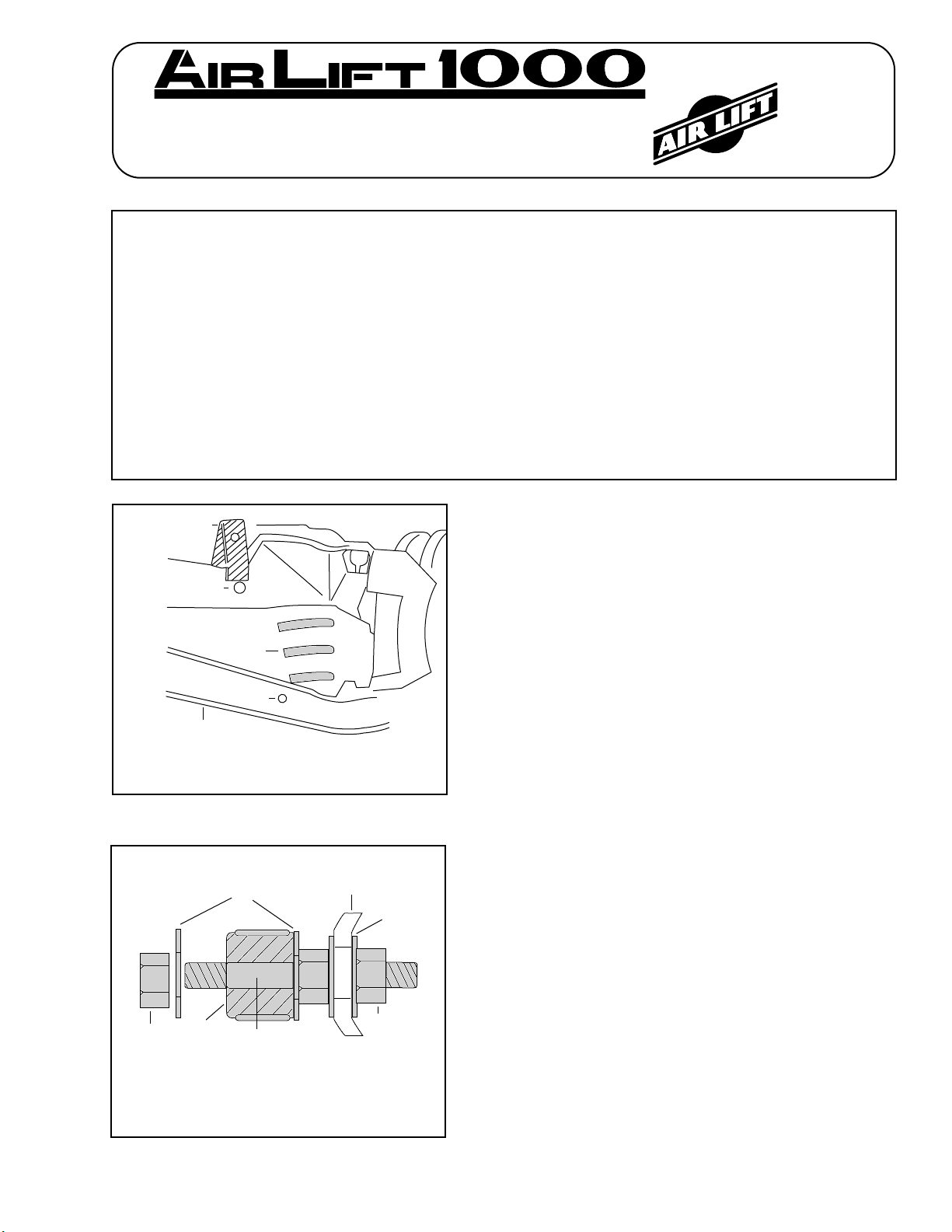

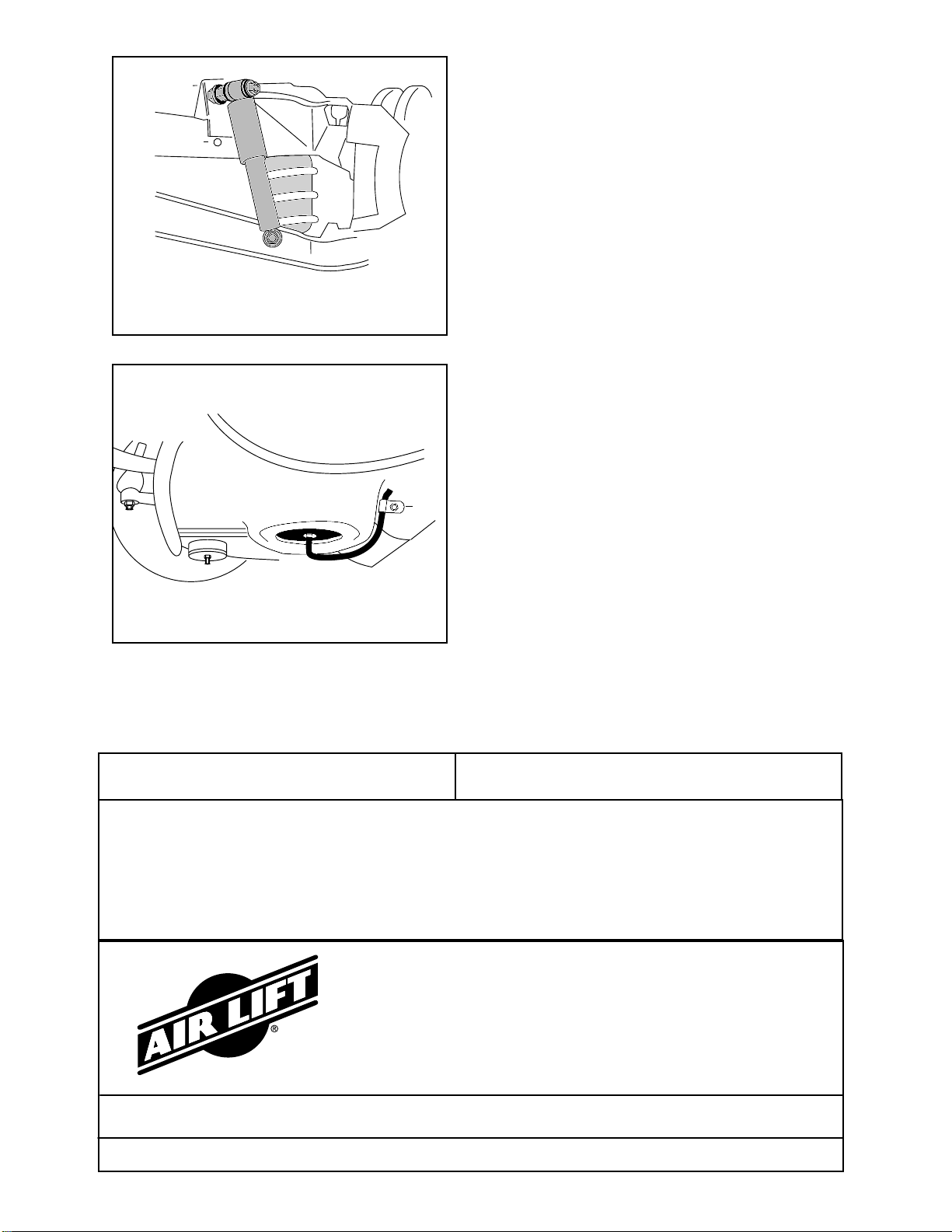

10. Guide the assembly through upper shock bolt hole

and attach with large washer (with 3/8” hole) and

3/8” nut. Hand tighten only at this time (Figure 3).

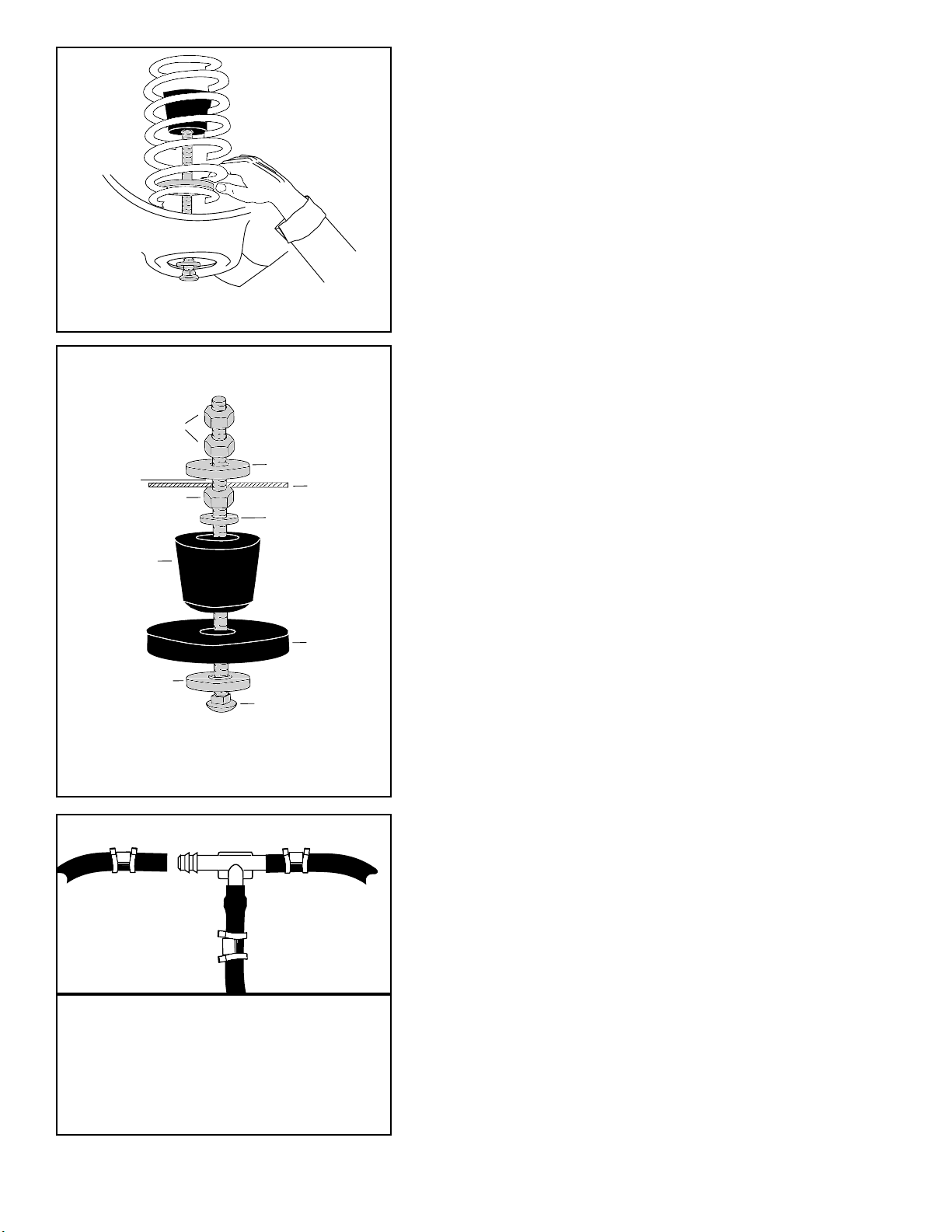

11. Remove black cap and squeeze air out of cylinder

and fold into a hot dog bun shape. Put black cap on

to retain deflated shape. Insert into lower spring

seat hole with stem down and push all the way into

spring (Figure 4). Slide thin spacer into spring at

bottom of cylinder and pull cap off so cylinder will

obtain its as molded shape.

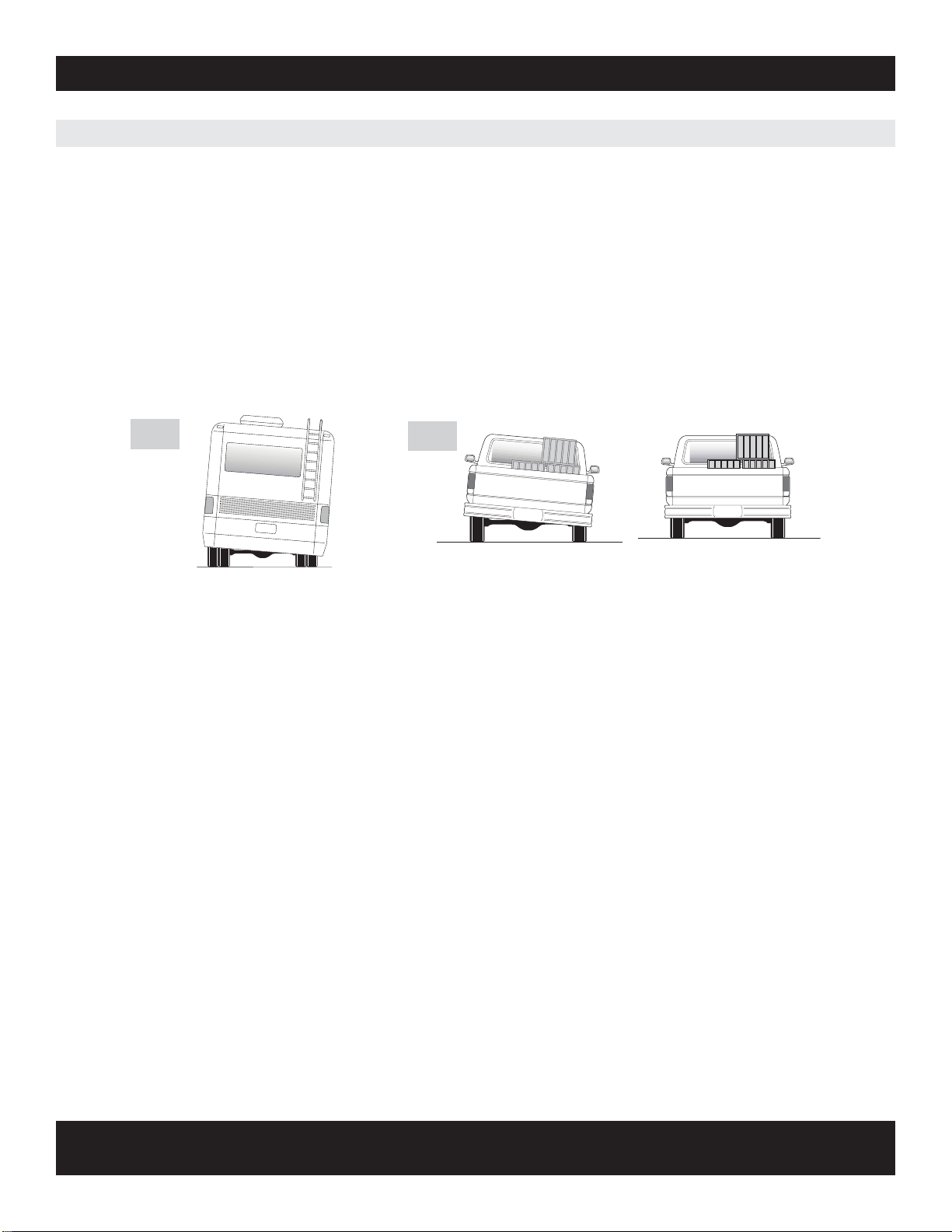

12. Install air line clamp onto air line and install air line

onto the barbed stem of cylinder. With pliers slide

the air line clamp until it fully covers barbed section

of stem (Figure 3A).

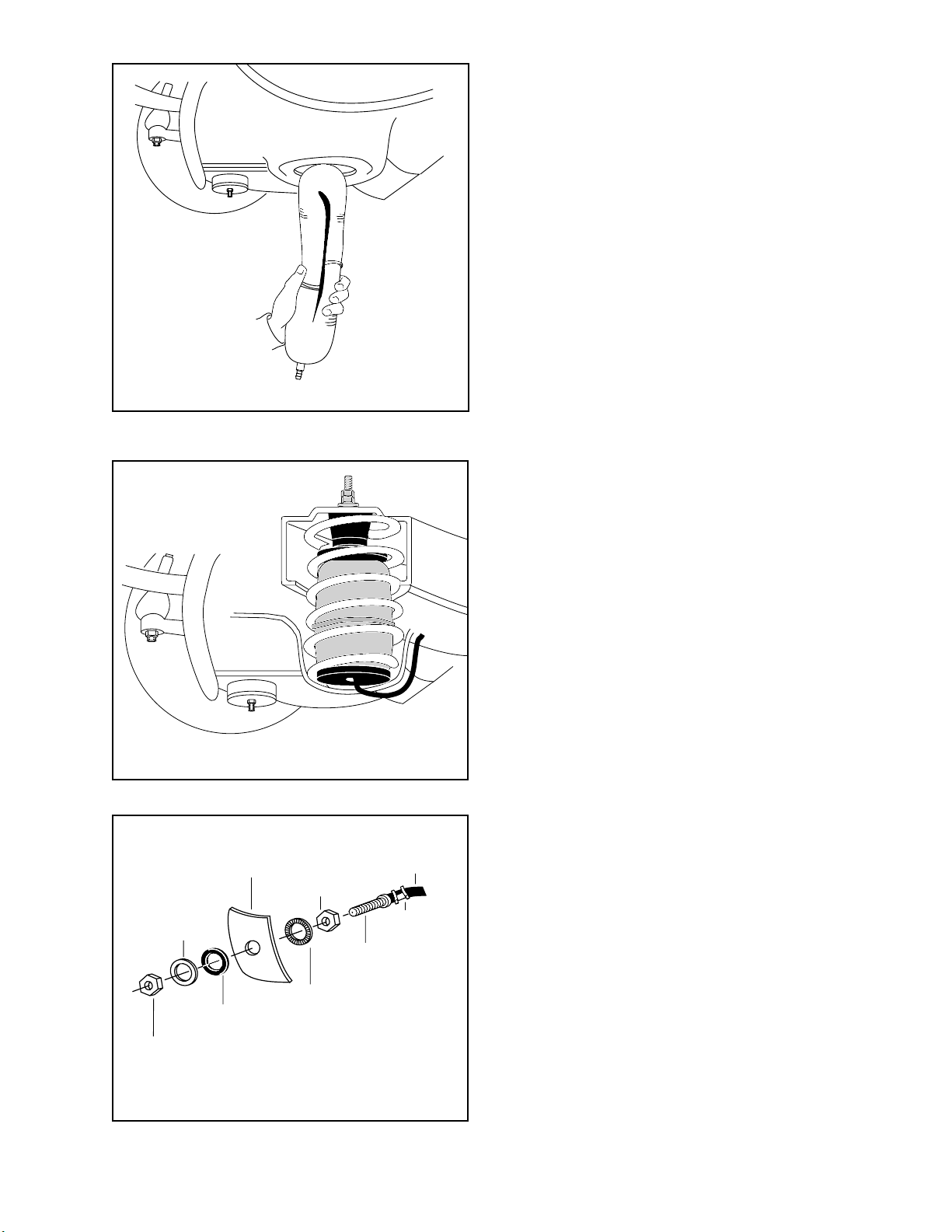

13. With air line installed on the cylinder, route airline

forward on inside of A-Arm. There are hose clips

and bolts supplied in the kit to attach air line to the

lower A-Arm. Locate and drill 3/8” hole. Attach the

clip to theA-Arm using the 3/8-16X1” bolts and nuts

supplied in kit (Figure 8). If air line is routed near a

high heat source (headers, manifold, etc.) use the

thermal sleeves supplied in effected areas.

Tee air line installation recommended unless weight in

vehicle varies from one side to the other and unequal

pressures are needed to level the load. Dual air lines are

used in this case.

TEE AIR LINE ROUTING

TO PREVENT AIR LINE FROM MELTING, KEEP IT AT

LEAST EIGHT INCHES FROM EXHAUST SYSTEM.

A. Locate desired tee location on the frame rail or

cross member.

B. Route along cross member from the lower spring

seat to tee location. Attach with plastic straps or

wire.

CAUTION: LEAVE SUFFICIENT AIR LINE SLACK TO

PREVENT ANY STRAIN ON FITTING DURING AXLE

MOTIONS.

C. Cut off excess air line and slide air line clamp onto

the air line. Push the air line over one side of the tee

until all the barbs are covered. Repeat procedure

for other leg of tee.

D. With pliers slide the air line clamp forward until it

fully covers the barbed section. Repeat for the air

line from the other air cylinder (Figure 3A).

E. Select a location for the inflation valve assuring that

the valve will be protected and accessible with an air

hose.

Figure 2