2

YOU COULD BE KILLED OR SERIOUSLY INJURED IF YOU DO NOT

READ AND UNDERSTAND THIS BOOKLET BEFORE USING THIS

PRODUCT.

SPECIAL TRAINING AND KNOWLEDGE ARE REQUIRED TO USE THIS

PRODUCT.

YOU MUST THOROUGHLY READ, UNDERSTAND AND REFER TO ALL

MANUFACTURER’S INSTRUCTIONS BEFORE AND AFTER EACH USE OF THIS

PRODUCT.

BEFORE USING THESE ROPES THE USER IS RESPONSIBLE TO DETERMINE

WHETHER THESE ROPES ARE SUITABLE FOR THE INTENDED USE AND THEIR

COMPATIBILITY WITH ALL HARDWARE TO BE USED.

USE AND INSPECTION OF THIS PRODUCT SHOULD ONLY BE DONE IN

ACCORDANCE WITH THE MANUFACTURER’S INSTRUCTIONS. INSPECTIONS

SHOULD ONLY BE CONDUCTED BY AN INDIVIDUAL DESIGNATED BY THE

EMPLOYER AS BEING COMPETENT FOR ALL TASKS REQUIRED.

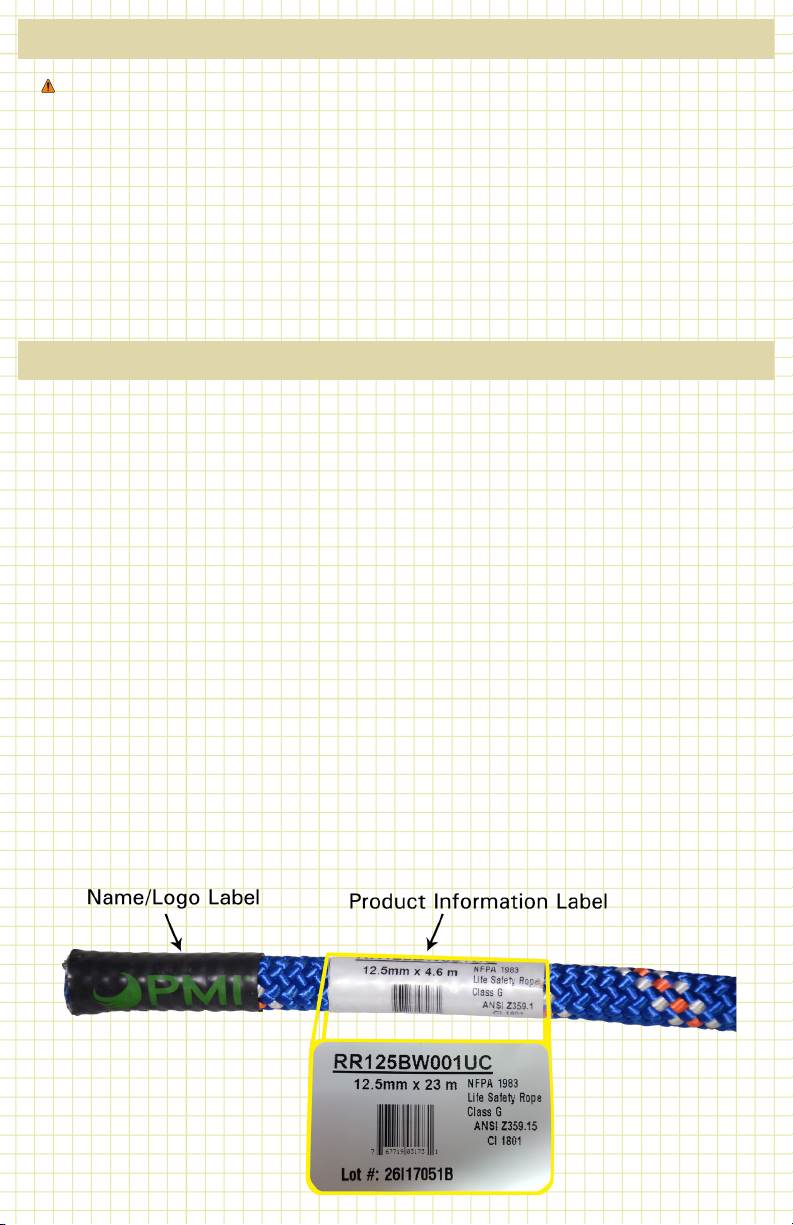

DO NOT MAKE ANY ALTERATIONS TO THIS PRODUCT. ALTERATIONS TO

ANY PMI ROPES IMMEDIATELY VOID THE WARRANTY WITH THE EXCEPTION

OF CUTTING ROPE LENGTHS FROM SPOOLS OR ADDING ID/LABELING

INFORMATION.

MANUFACTURER’S INSTRUCTIONS SHALL BE PROVIDED TO USERS.

ROPES SHOULD NOT BE USED NEAR MOVING MACHINERY, ELECTRICAL

HAZARDS, SHARP EDGES, OR ABRASIVE SURFACES WITHOUT PROPER

ADDITIONAL SAFETY EQUIPMENT IN PLACE. IN ADDITION, ROPES SHOULD

BE PROTECTED DURING STORAGE, TRANSPORT AND USE, AS THEY CAN

MELT OR BURN AND FAIL IF EXPOSED TO FLAME OR HIGH TEMPERATURE.

PROTECT YOUR ROPE FROM ANYTHING THAT MIGHT DAMAGE IT, SUCH AS

ABRASION, ABRASIVE SURFACES, HEAT, AND CHEMICALS. A PROTECTIVE

ROLLER, PADDING, OR OTHER ITEM SHOULD BE PLACED BETWEEN THE ROPE

AND ANY SHARP EDGE.

PMI IS NOT RESPONSIBLE OR LIABLE IN ANY WAY FOR DAMAGES OF ANY

KIND, INJURY OR DEATH RESULTING FROM DIRECT OR INDIRECT INCIDENTS

RELATED TO THE USE OF ITS PRODUCTS.

IF YOU HAVE PURCHASED A ROPE WITH FACTORY TERMINATIONS, REFER

TO THE SECTION IN THESE INSTRUCTIONS TITLED “PMI TERMINATIONS”.

PLEASE CONTACT PMI AT 706-764-1437 TO ANSWER ANY ADDITIONAL

QUESTIONS REGARDING SAFETY INFORMATION AND THE USE OF THIS

PRODUCT.

ABOUT YOUR PERSONAL SAFETY

YOUR PERSONAL SAFETY IS JUST THAT...PERSONAL. YOU ARE

RESPONSIBLE FOR YOUR OWN SAFETY. WE BUILD THE BEST POSSIBLE

PRODUCTS FOR THE PURPOSES STATED, BUT IT IS UP TO YOU TO BE

RESPONSIBLE FOR USING THESE, AND OTHER PRODUCTS, SAFELY.

YOUR PERSONAL SAFETY IS INFLUENCED BY THE DECISIONS YOU MAKE.

TAKE THE TIME TO READ AND UNDERSTAND THESE INSTRUCTIONS, AND

GET THE TRAINING YOU NEED FOR YOUR APPLICATION. THE HIGH ANGLE

ENVIRONMENT IS A POTENTIALLY DANGEROUS ONE. WE HOPE YOU TAKE IT

AS SERIOUSLY AS WE DO.

WARNINGS