Before you start

To achieve the best possible result when ironing, the laundry shall

be lightly moist. Never iron textiles with buttons, zippers etc.

Start

Make sure that the power switch is on. Decide which type of

ironing method to use by consulting the section “ Cold ironing

techniques”

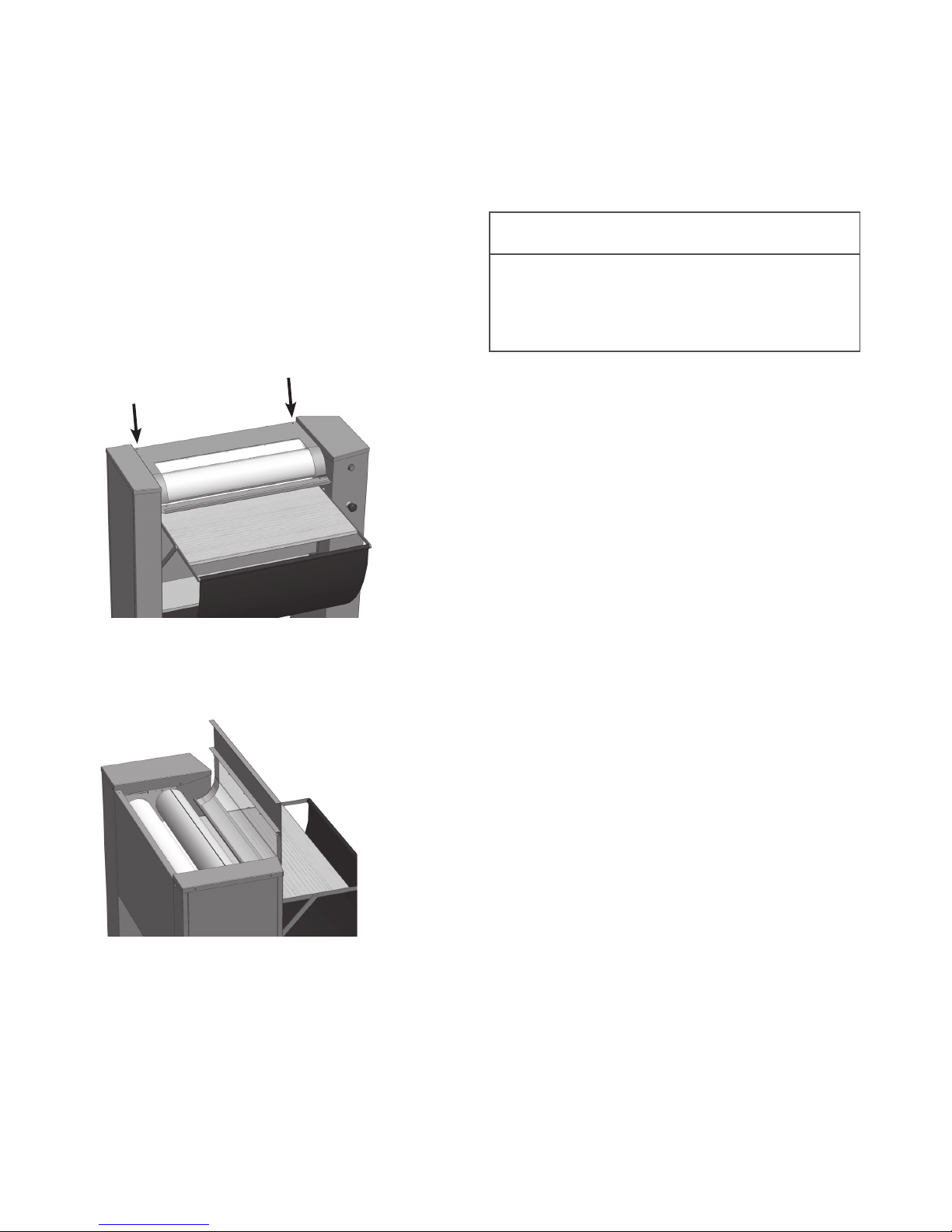

Flip down the manoeuvre shield and let the moving rollers grab

your textiles. Keep the textiles and the iron cloth tensioned

during the complete process.

In you want to pause the process flip the manoeuvre shield up

to the position Stop.

When the complete textile is fed into the rollers, let the cold

ironer work for 2-3 minutes (skip this step when ironing using

the technique “Ironing without iron cloth”).

Stop

Flip the manoeuvre shield up to the horizontal position to make

the rollers stop. This stop function should not be confused

with the finger protection function.

Reverse/release

When the manoeuvre shield is flipped to the position,

Reverse/release the cold ironer reverse. After a few seconds the

rollers separate, and the textiles can easily be taken out.

When you are finished

Always leave the iron cloth to dry freely in the collecting tray

under the feeding table.

Leave the manoeuvre shield in the horizontal position, Stop.

Turn off the power switch.

Cold ironing techniques

There are several techniques to use when cold ironing. In the

section below we present the most common techniques.

Cold ironing on the inside of the iron cloth

Napkins, towels and other small to normal sized textiles are

ironed inside the iron cloth. The iron cloth is pulled out entirely.

Place the textile on the iron cloth, close to the rollers. Flip the

manoeuvre shield down to the position, Start/forward. Feed the

textile into the iron cloth, evenly. Iron the textile for 2-3 minutes.

Cold ironing on the outside of the iron cloth

Larger textiles such as bed linens, table cloths etc. are ironed on

the outside of both roller and iron cloth. The iron cloth should be

wrapped around the roller. Make sure that the iron cloth is fed

onto the roller evenly. Leave a few decimeters of iron cloth out,

to attach the textile to be ironed. Place the textile directly on the

iron cloth that is sticking out. Flip the manoeuvre shield down to

the position, Start/forward. The top part of the textile is fed into

the iron cloth and the rest of the textile wraps around the outside

of the rollers. Pull gently on the textile to reduce wrinkles.

Cold ironing without the iron cloth

Very large textiles should be ironed with the iron cloth com-

pletely wrapped around the rollers. Place the textile between

the roller with the iron cloth and the aluminium roller below. The

textile is ironed and falls down into the collecting tray under the

feeding table. Repeat the procedure until satisfaction.

If the cold ironer stops

The cold ironer stops if it is overloaded. Follow the instructions

below; if the cold ironer stops during the process of ironing or if

the rollers does not move when using the manoeuvre shield.

• The cold ironer is equipped with an input stop. When the rollers

are overloaded with textiles, the cold ironer stops. Flip up

the manoeuvre shield to the position, Reverse/release.

Remove the textiles by hand. Iron less textiles or change iron-

ing technique and try again.

• If what stated above does not work, the motor might be over-

loaded. This occurs when too heavy textiles are fed into the

rollers. To reset the motor overload protection, push the blue

button on the right side of the ironer.

• If none of the above works. Check the emergency stop.

Reset the emergency stop by turning the handle clock-wise.

WARNING

Do not reach for or touch the rollers when they are mov-

ing or when they are stopped. - Risk for severe squeezing.

Do not allow children to play on or around the cold ironer.

DO NOT bypass any safety devices.

REVERSE

STOP

FORWARD

STOP