3

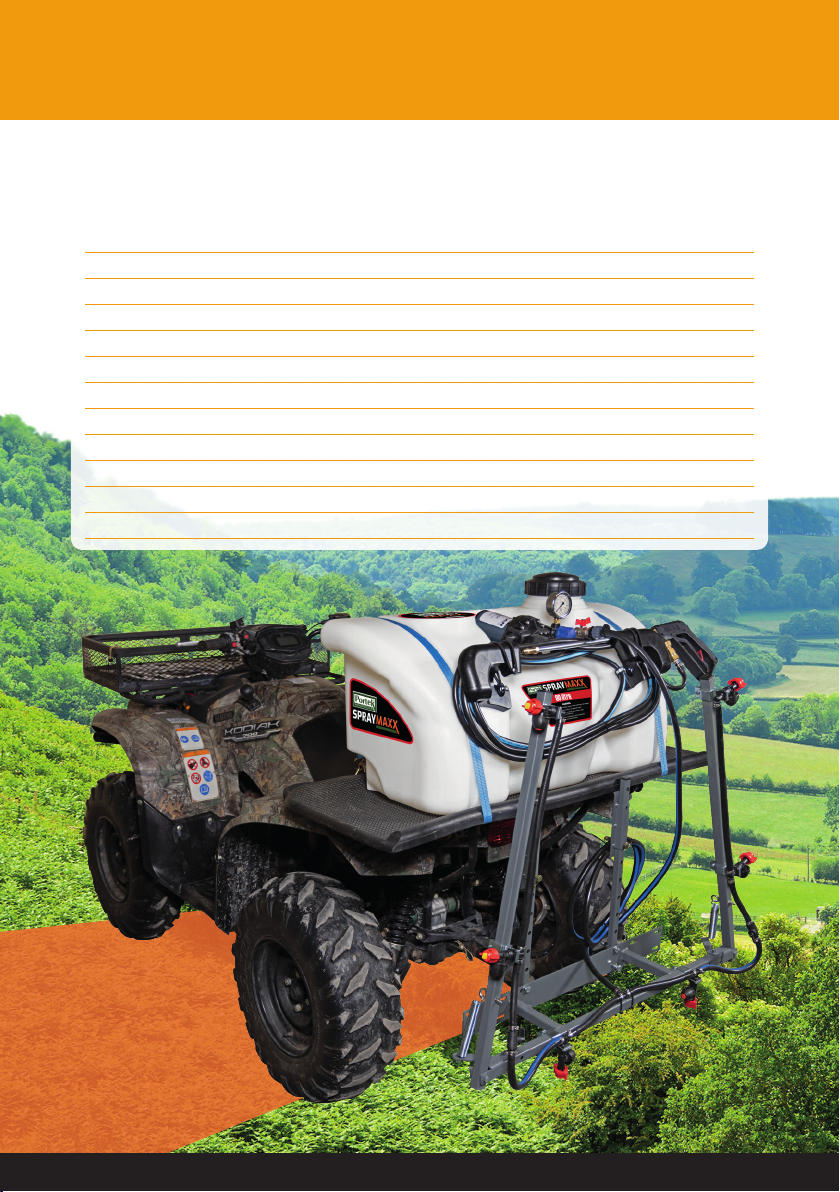

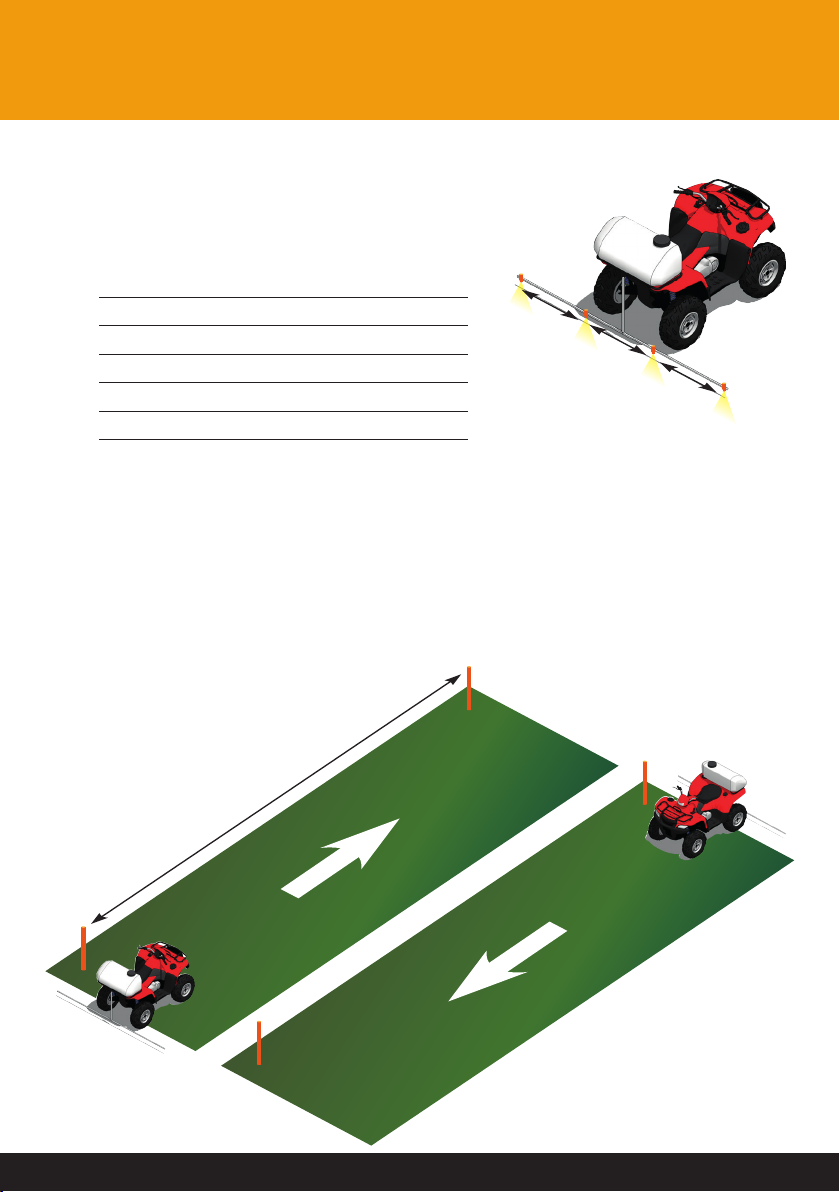

This user manual accompanies the SprayMaxx ATV/UTV Mounted Sprayer and contains

important information on set up and handling. Before using the equipment, read the user

manual carefully. This particularly applies to the safety notes. Failure to do so may result in

personal injury or damage to the equipment. Store the user manual for further use.

This graphic accompanied by the words WARNING and DANGER

highlights an act or a condition which can lead to SERIOUS INJURY.

ALWAYS WEAR THE CORRECT PROTECTION.

Before You Start

!

READ AND UNDERSTAND THIS MANUAL

FULLY BEFORE OPERATING THE SPRAYMAXX

RESIDUAL RISKS

This machine is only designed for the spraying of herbicides and pesticides. Use the product

only if you fully understand all the functions and can perform without restrictions, or have

received appropriate instructions. Respect technical data and safety precautions. Do not use this

product in any other way as stated for normal use. Not observing general regulations in force

and instructions from this manual does not make the manufacturer liable for damages.

Please note that our equipment has not been designed for commercial, trade or industrial use.

If the equipment is used in commercial, trade or industrial operation or for similar activities, we

cannot assume any liability. Specifications, descriptions and illustrative material in this manual

are as accurate as known at the time of publication, but are subject to change without notice.

Illustrations may include optional equipment and accessories, and may not include all standard

equipment.

Even when the device is used properly and all safety regulations are complied with, there still

may be some residual risks, which cannot be prevented.

ALWAYS WEAR SAFETY CLOTHING IN CONJUNCTION WITH HAND, EYE, HEAD,

HEARING AND FOOT PROTECTION TO HSE/EN SPECIFICATIONS