3

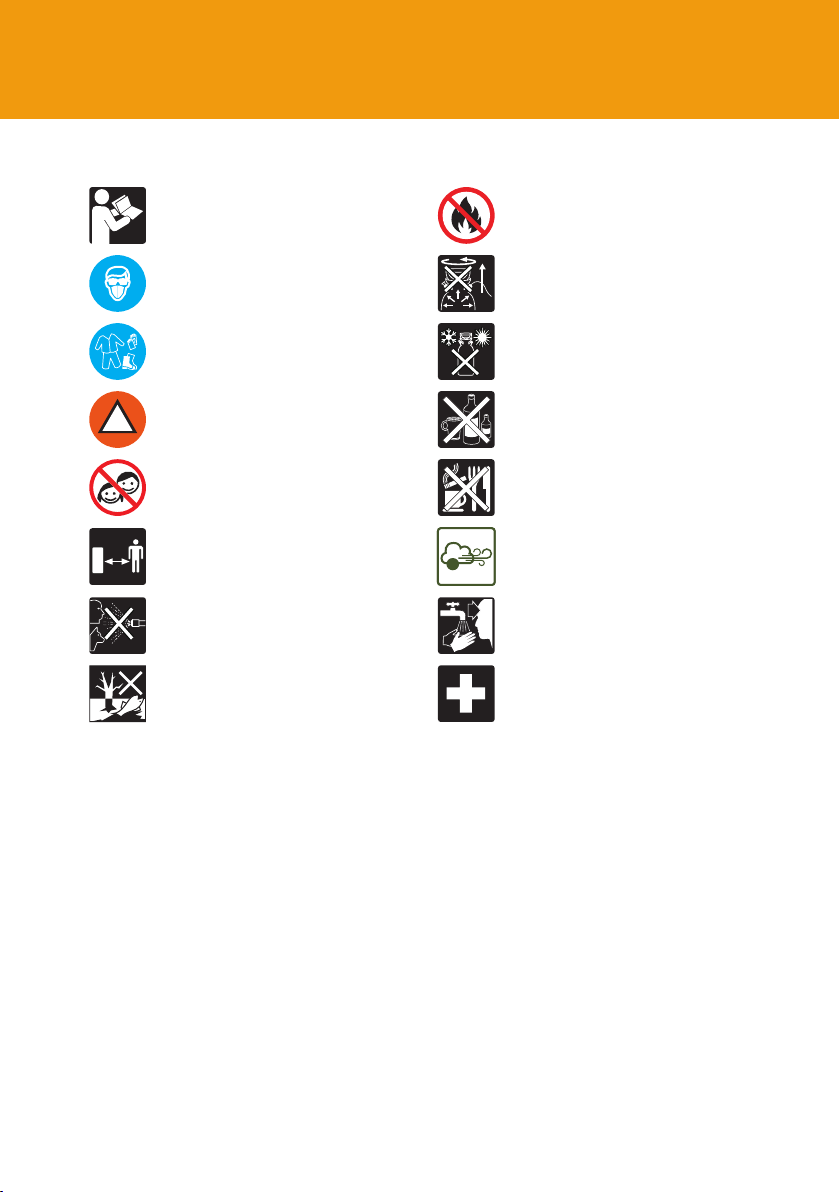

Symbol Meaning Symbol Meaning

Read instruction manual

before use. Do not burn.

Use suitable face mask

and eye protection.

Never open the pump

when under pressure.

Use suitable protective

clothing during use.

Do not leave the sprayer exposed

to heat sources or intense cold.

!Denotes risk of personal

injury or damage to the tool.

Do not use for spraying food

products (ie: wine, milk, etc.).

Children shall not play

with the appliance.

Do not eat, drink

or smoke during use.

Keep bystanders away

whilst using the sprayer.

Do not spray on

windy days.

Do not spray toxic or harmful liquids

on persons, animals or foodstuffs.

Wash hands and

face after use.

Never abandon potentially hazardous

chemicals in the environment,

drainage or sewerage systems.

Seek medical attention if spray

gets in eyes, or if other symptoms

develop during spraying.

Note: After use, rinse the container then operate the pump with clean water to completely empty the

container and piston.

Safety Information

DISPOSAL

At the end of the EZY Spray’s working life, or when it can no longer be repaired, ensure that

it is disposed of according to national regulations. Contact your local authority for details of

collection schemes in your area.

• Do not incinerate.

• Do not abandon in the environment. When using chemical products, consult the

corresponding documentation for the correct method of disposal of any excess materials. If

in any doubt, seek advise from your local authority or a certified disposal contractor.

• Do not dispose of excess chemicals into drainage/sewerage systems or into the natural

environment. If disposed of in landfills or dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging your health and well-being.