From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

PALS 4000 & 5000

Automatic

Label

Sewers

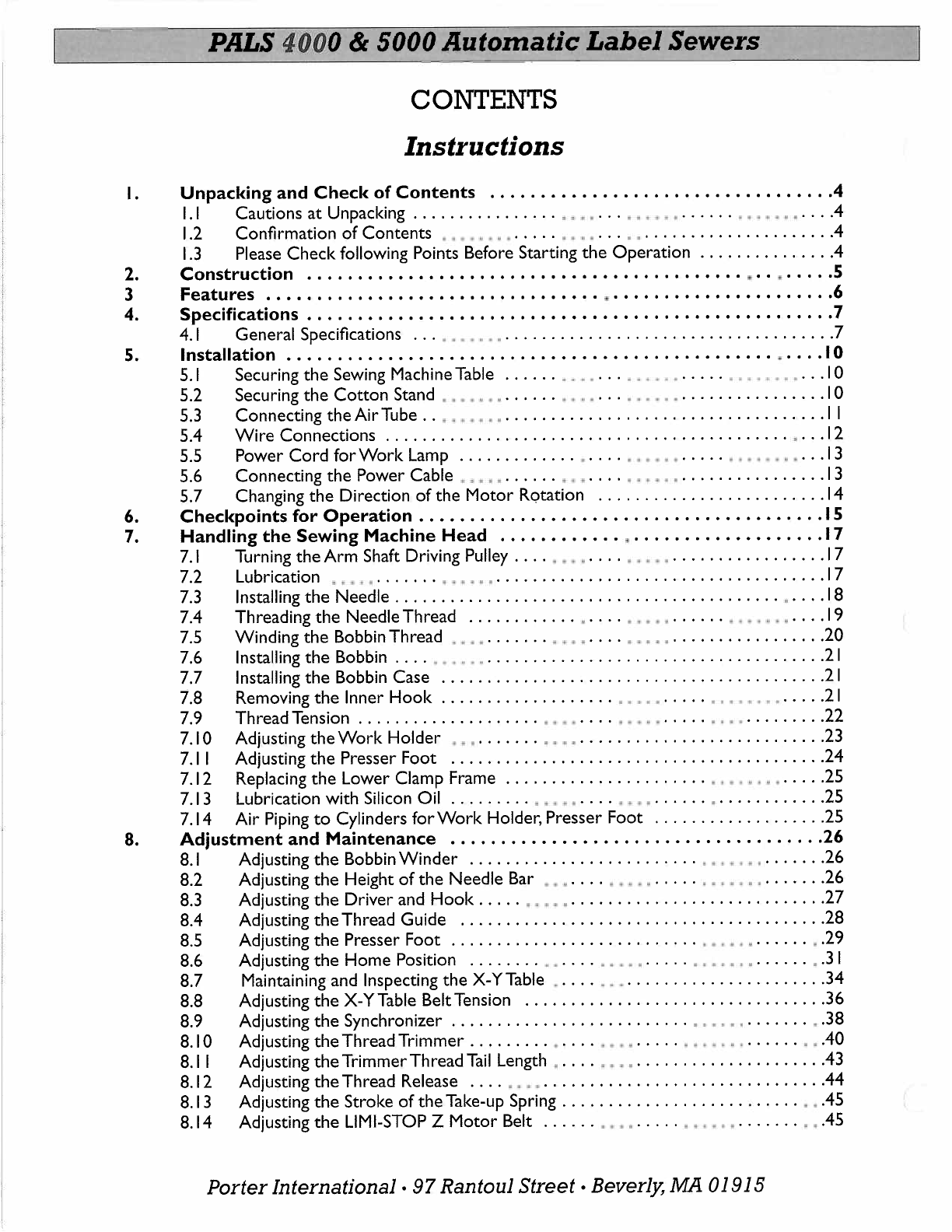

CONTENTS

Instructions

I.

Unpacking and Check

of

Contents

.................................

.4

1.1

Cautions

at

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . ••

...

.4

1.2

Confirmation

of

Contents

. . . . . . .

....

.•..

...

..

....................

.4

1.3

Please

Check

following Points Before Starting

the

Operation

..............

.4

2.

Construction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....

S

3

Features

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................

6

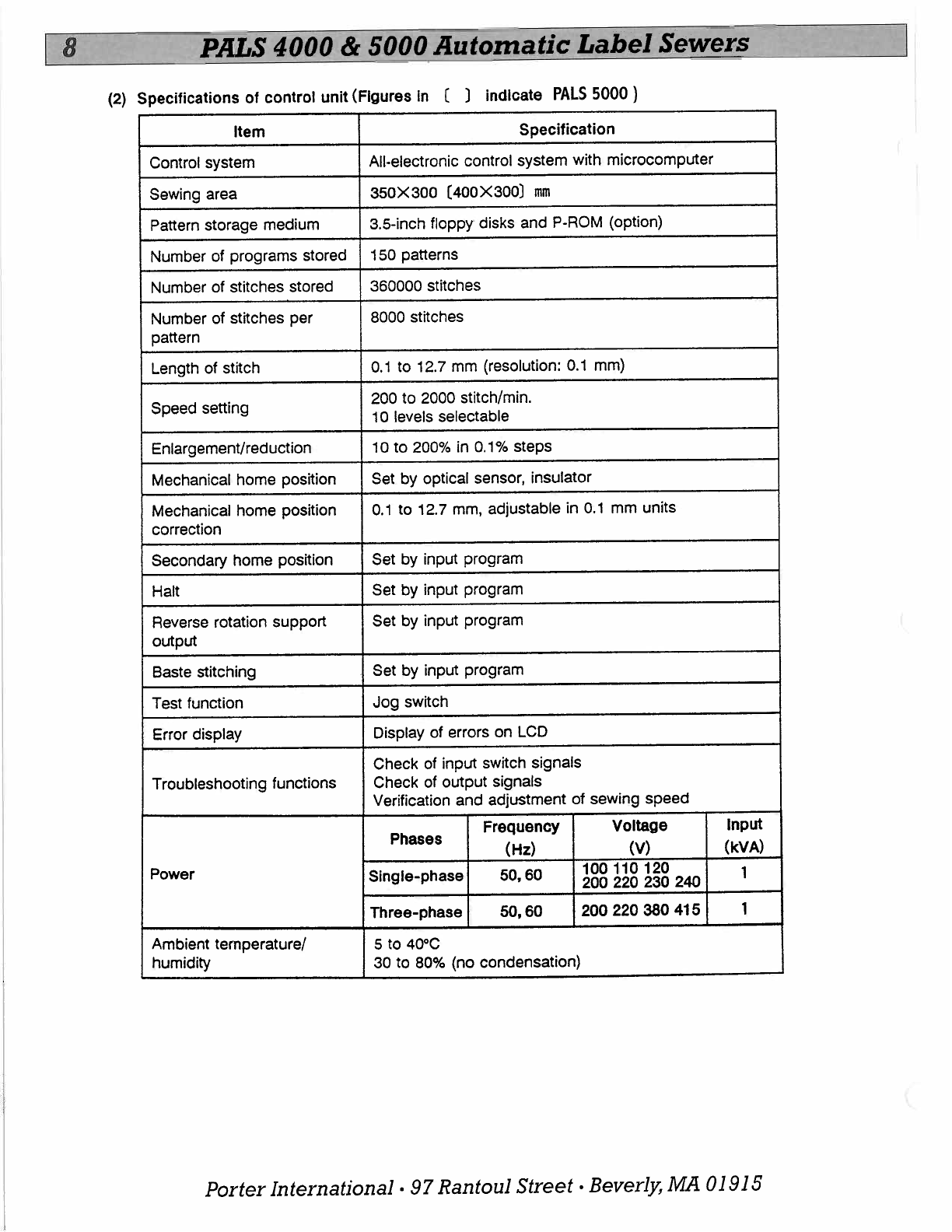

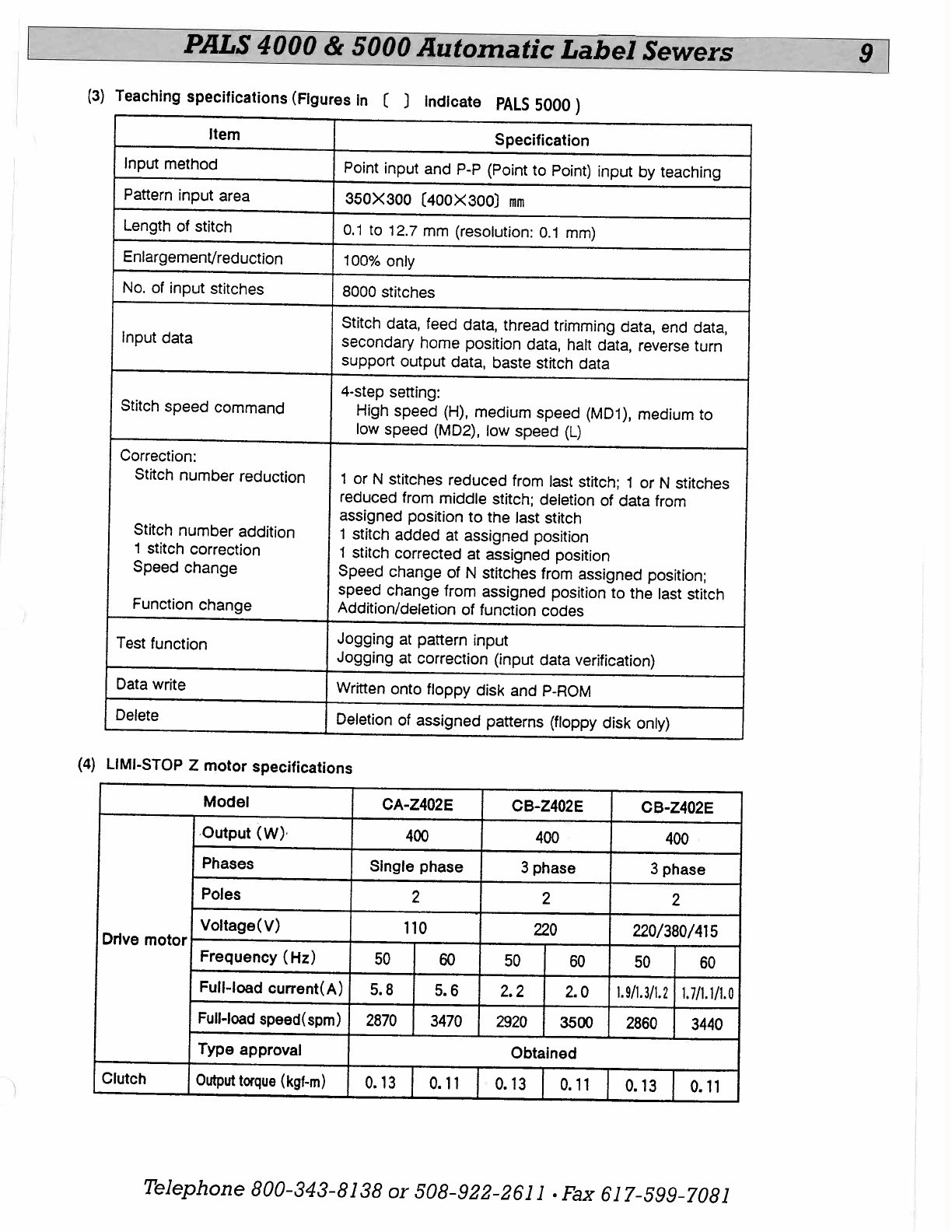

4.

Specifications

....................................•...............

7

4.1

General Specifications . . . . . .

...

...............

.

...................

.7

5.

Installation

................................................

.

....

I0

5.1

Securing

the

Sewing Machine Table . . . . . . . . . . . . . . . . . . . . . . . • . . • ,

...

I0

5.2 Securing

the

Cotton

Stand . . . .

......

....

...

..•...

................

I0

5.3 Connecting

the

AirTube

..

, . •••

...................................

I I

5.4

Wire

Connections

............................................

.

...

12

5.5 Power

Cord

for

Work

Lamp . . . . . . . . . . . . . . . . . • . • . . . . . . . .

...

...

13

5.6 Connecting

the

Power Cable

...

, . . . . . . . • . . . . •. . •

................

13

5.7 Changing

the

Direction

of

the

Motor

Rotation

.........................

14

6.

Checkpoints

for

Operation

........................................

I5

7.

Handling

the

Sewing Machine

Head

............

.

..................

.

17

7.1

Turning

the

Arm Shaft Driving Pulley . . . . . • . . . . . . . . . .

.................

17

7.2 Lubrication . • •, . . . . . . . • .

.•

....................................

17

7.3 Installing

the

Needle

..........................................

.

....

18

7.4 Threading

the

NeedleThread . . . . . . . . . . . . . . . . . . . •. . . . . . . . .

......

.

19

7.5 Winding

the

Bobbin Thread . • . . . . . . . . • • .

...

•.•..

.................

20

7.6 Installing

the

Bobbin . . . . • .

...

.....................................

21

7.7 Installing

the

Bobbin Case

..........................................

21

7.8 Removing

the

Inner

Hook

. . . . . . . . . . . . . . . . . . . . . . . •. . . . . . •• . . •

.....

21

7.9 ThreadTension

....................

•.

....

.•...

.....

•••.

.........

22

7.10 Adjusting

the

Work

Holder •. . . . . . . . . .

...........................

23

7.1

I Adjusting

the

Presser

Foot

.........................................

24

7.12 Replacing

the

Lower Clamp Frame . . . . . . . . . . . . . . . . . . . . . . •. . . .

....

25

7.13 Lubrication with Silicon Oil . . . . . . . . . . . •. . . . • • •

......

.

............

25

7.14 Air Piping

to

Cylinders for

Work

Holder,

Presser

Foot

...................

25

8.

Adjustment

and

Maintenance

.....................................

26

8.1

Adjusting

the

Bobbin

Winder

. . . . . . . . . . . . . . . . . . . . . . . . . . . • • ,

.......

26

8.2 Adjusting

the

Height

of

the

Needle Bar . . . . . • . . • . . . . . . . • . •

..

.......

26

8.3 Adjusting

the

Driver and

Hook

. . . . . • . •

............

.

...............

27

8.4 Adjusting

the

Thread Guide

........................................

28

8.5 Adjusting

the

Presser

Foot

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

•••

......

, .29

8.6 Adjusting

the

Home

Position

.......

.

..

....

...•

,

.....

, . • . . .

......

. .3 I

8.7 Maintaining and Inspecting

the

X-YTable .

....

..•

......................

34

8.8 Adjusting

the

X-Y Table BeltTension

.................................

36

8.9 Adjusting

the

Synchronizer

..........................

..•..

,

.......

• .38

8.10 Adjusting

the

ThreadTrimmer . . . . . . . . . . . . . . .

.....

.......

......

..

.40

8.1

I Adjusting

the

TrimmerThread

Tail

Length • . . . . . • .

....................

.43

8.12 Adjusting

the

Thread Release

....

..•.

..............................

.44

8.13 Adjusting

the

Stroke

of

the

Take-up Spring

...............

.

....

.

.....

.•

.45

8.14 Adjusting

the

LIMI-STOP

Z

Motor

Belt

......

. ,

..

.....

.•

, . .

.......

.•

.45

Porter

International•

97

Rantoul

Street•

Beverly,

MA

OJ

915