CONTENTS

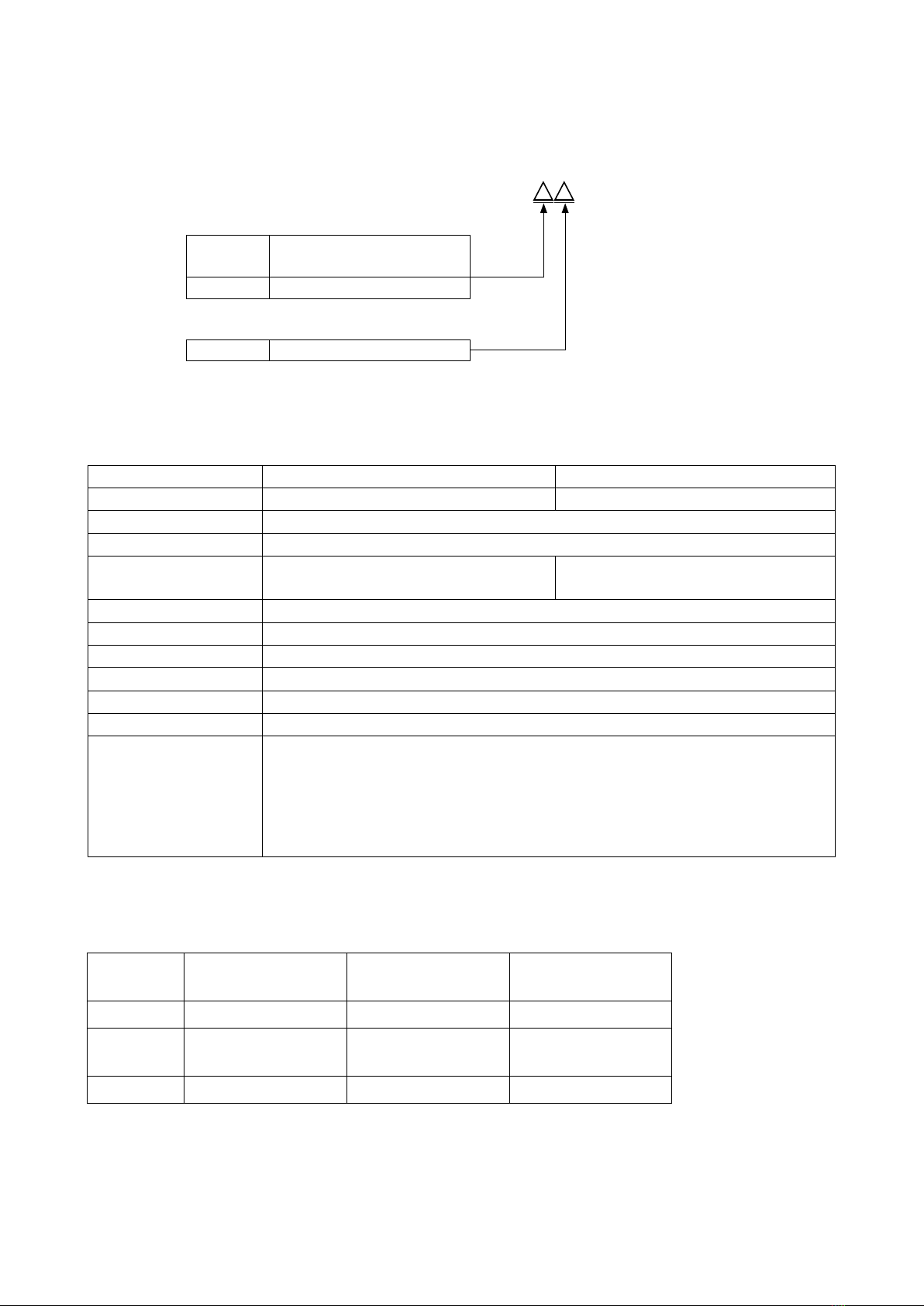

1. SPECIFICATIONS............................................................................................................ 1

1-1. Specications of the sewing machine head ..................................................................... 1

1-2. Specications of the control box....................................................................................... 1

2. SETUP.............................................................................................................................. 2

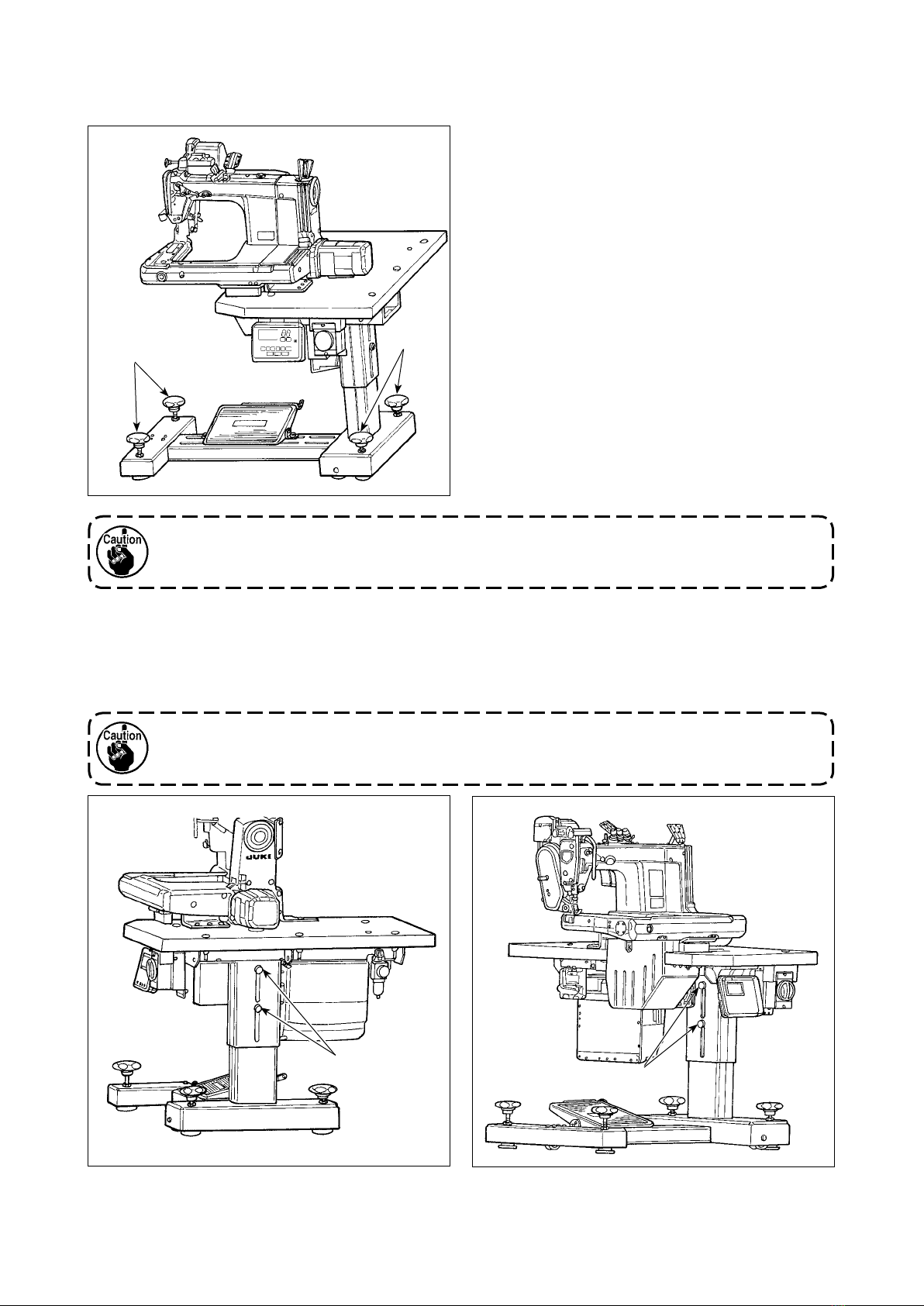

2-1. Setting up the sewing machine.......................................................................................... 2

2-1-1. Adjusting the sewing machine head........................................................................................ 2

2-1-2. Changing the position of the operation panel ........................................................................3

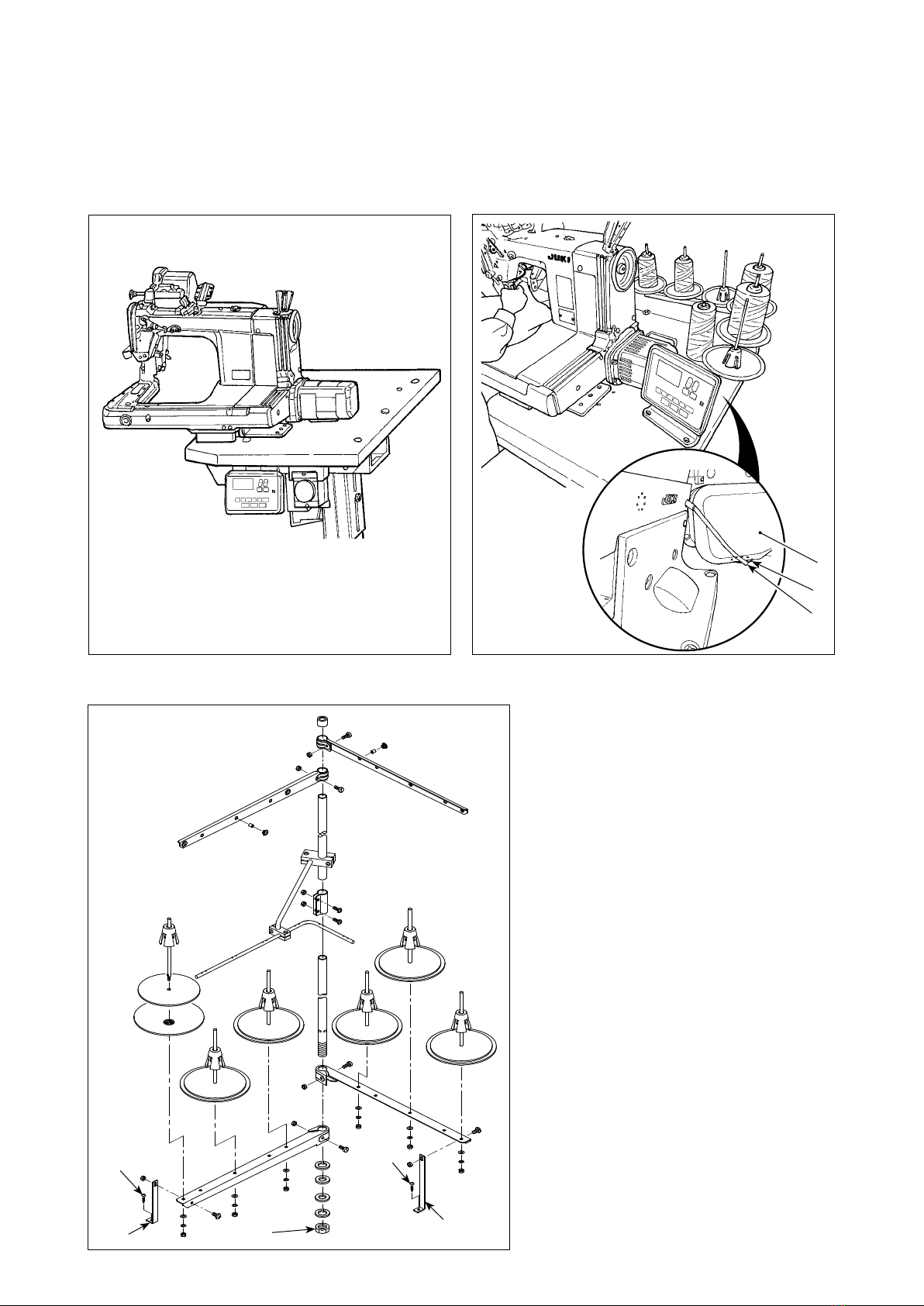

2-2. Installing the thread stand.................................................................................................. 3

2-3. Oiling and draining of oil .................................................................................................... 4

3. PREPARATION BEFORE SEWING ................................................................................ 5

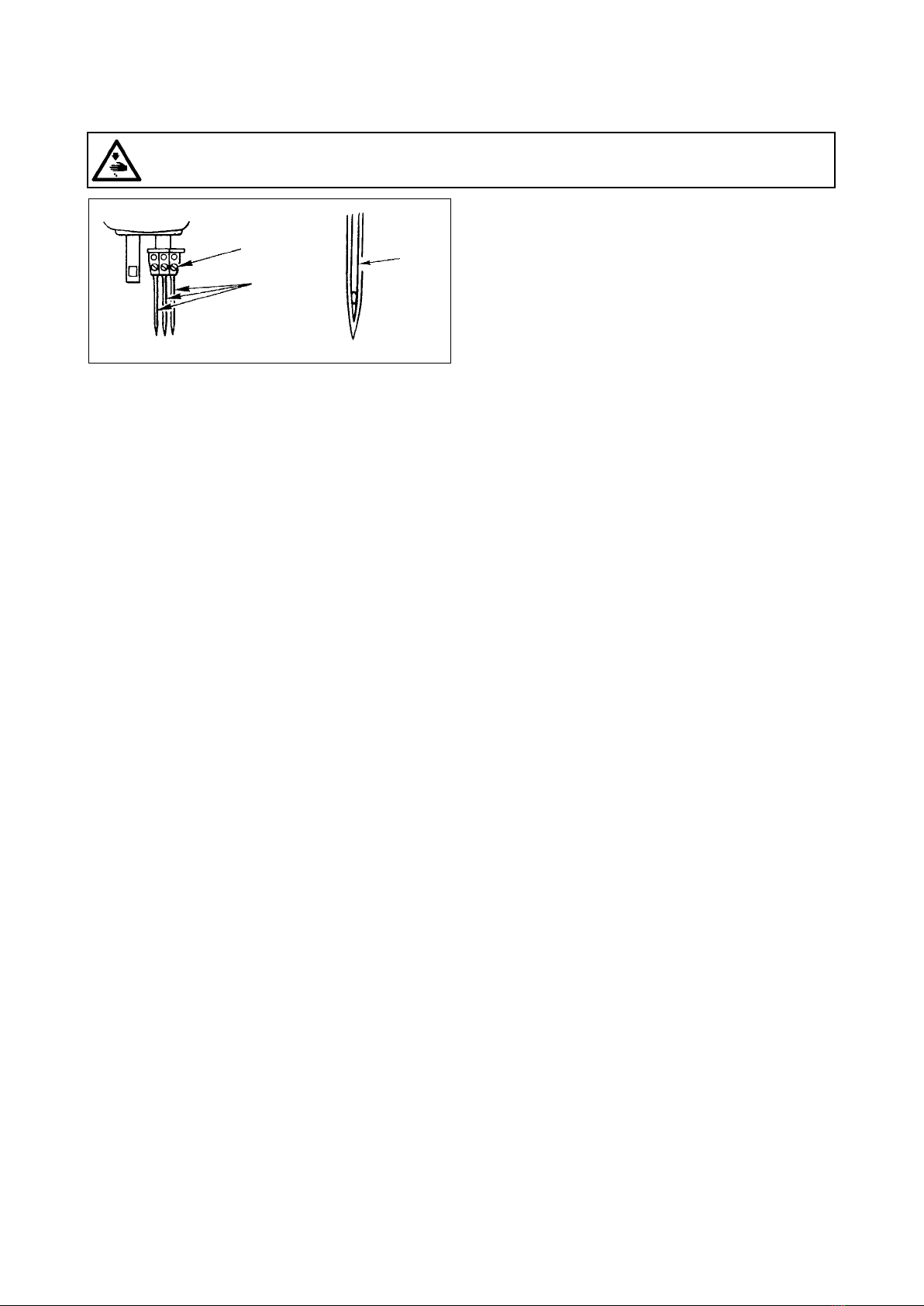

3-1. Attaching the needle ........................................................................................................... 5

3-2. Threading the machine head.............................................................................................. 6

3-3. Adjusting the thread tension.............................................................................................. 7

3-4. Adjusting the stitch length ................................................................................................. 8

3-5. Adjusting the needle guard ................................................................................................ 9

3-6. Adjusting the looper thread cam...................................................................................... 10

3-7. Adjusting the feed dog height.......................................................................................... 10

3-8. Adjusting the take-up thread tension control lever........................................................ 11

3-9. Adjusting the position of the intermediate tension release lever and needle thread

tension controller .............................................................................................................. 11

3-10. How to adjust the cloth puller .......................................................................................... 12

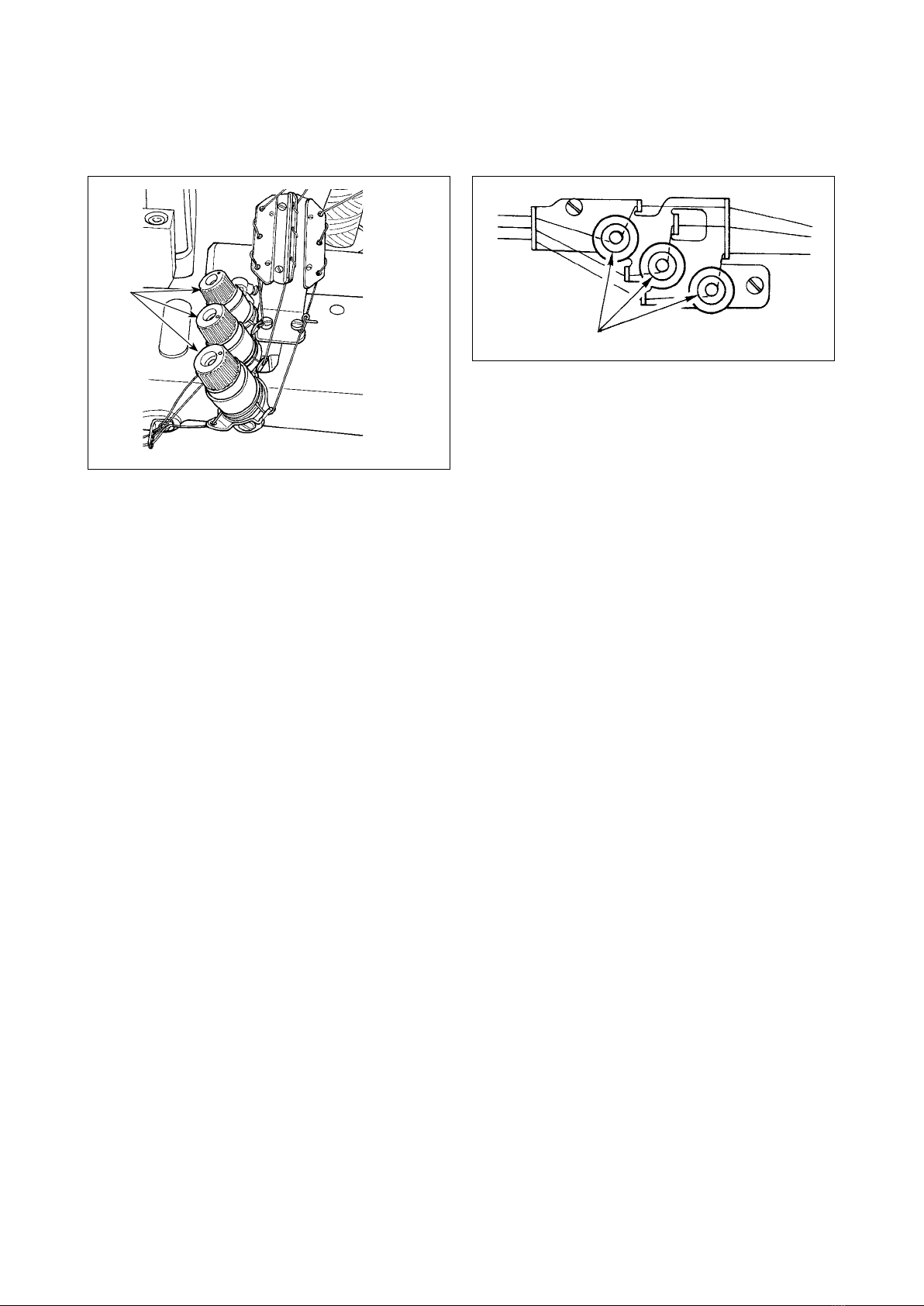

3-10-1. Adjusting the cloth puller belt and its longitudinal position ............................................. 12

3-10-2. Adjusting the inclination of the cloth puller belt.................................................................13

3-11. LED hand light ................................................................................................................... 13

3-12. To use the sewing machine with a cloth puller for sewing heavy-to medium-weight

materials............................................................................................................................. 14

3-12-1. Replacing the feed dog .........................................................................................................14

3-12-2. Changing the throat plate .....................................................................................................14

3-12-3. Adjusting the difference in height of the presser foot ...................................................... 15

3-12-4. Replacing the needle thread guide ......................................................................................15

3-13. Table of replaceable gauges............................................................................................. 16

3-14. Adjusting the material edge detector .............................................................................. 17

3-15. Needle cooler ..................................................................................................................... 18

3-15-1. Adjusting the position of the blow pipe............................................................................... 18

3-15-2. Adjusting the air ow.............................................................................................................18

3-16. Chain-off thread cutter (suction of thread waste) .......................................................... 18

4. HOW TO USE THE OPERATION PANEL ..................................................................... 19

4-1. Explanation of the operation panel switch ..................................................................... 19

4-2. Operation to be done at rst ............................................................................................ 20

4-2-1. Selection of the language .......................................................................................................20

4-3. How to select a sewing pattern........................................................................................ 23

4-4. How to change the sewing data ....................................................................................... 24

4-4-1. Method of changing the sewing data.....................................................................................24

4-4-2. Method of selecting a specic sewing data item..................................................................24

4-4-3. How to change the part number, process or comment for the sewing pattern data......... 26

i