Install sensor in

bottom 1/3 of

dipper arm

String Line

Dipper sensor

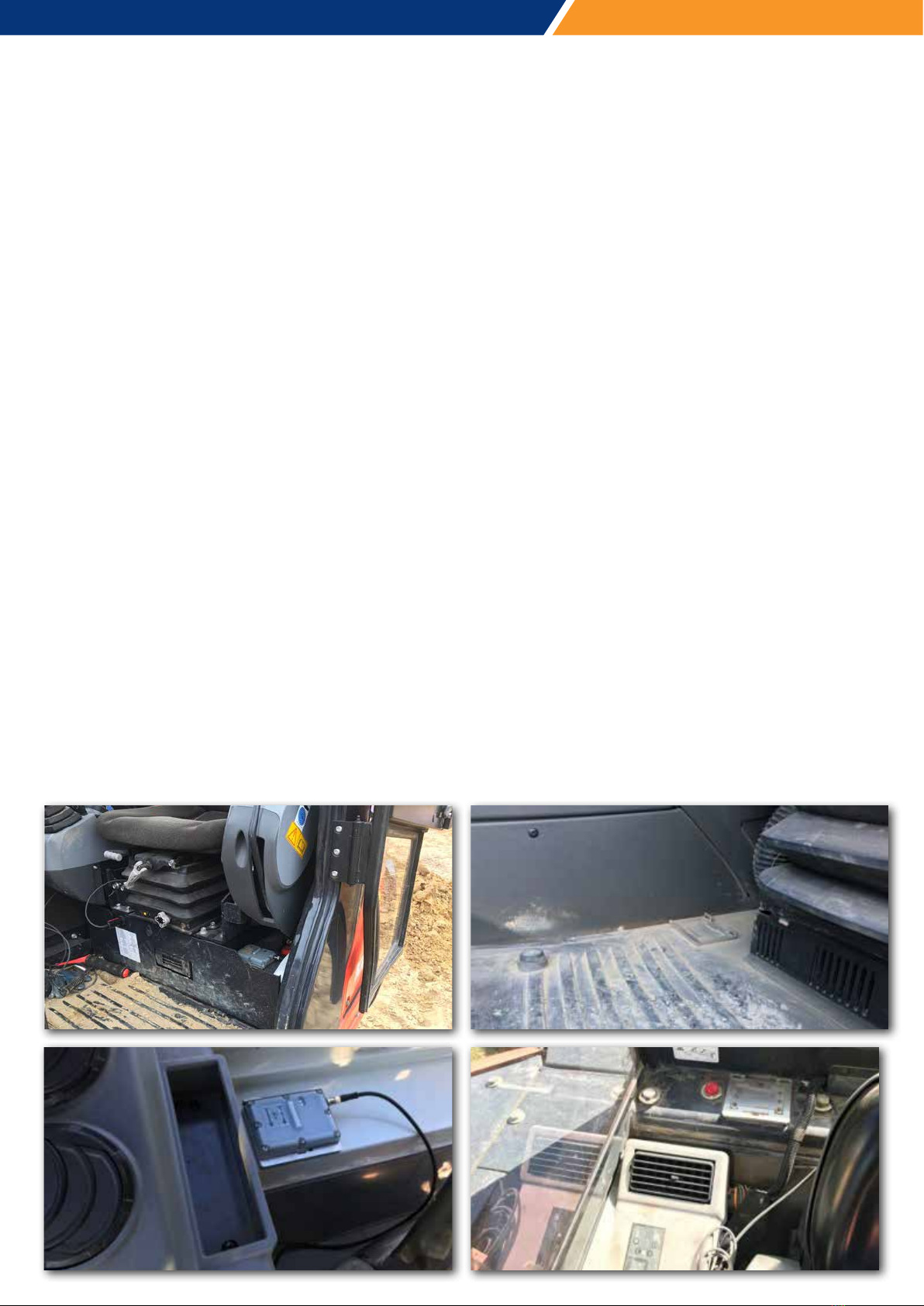

The dipper sensor will need to be located on the dipper arm as low as possible.The higher the sensor is

located on the dipper stick, the more the boom and dipper has to be dropped to catch the beam. Be aware

of the location of hoses and pipes that may inhibit a clear line of sight to the sensor when using the laser

catch function.

Be aware of the crush zone of the dog bone coming onto the arm as the bucket crowds in and out.

Note also where any auxiliary hoses are being plugged in and out that may spill oil onto the sensor.

These locations are to be avoided avoided if possible.

For more accurate calibration and ease of setup regarding the laser catch function, you may want to

consider installing the dipper sensor using the following directions. This will allow you to manually enter

accurate measurements into the laser calibration setup stage and the system will be maximally accurate

when using the laser catch function.

You will want to rotate the dipper sensor forward (counter clock-wise) slightly 10°-15° from when the

Dipper arm is set at 90° to the ground. This again helps with catching the laser.

Suitably clean the chosen area with brake cleaner and wipe dry. Clean the surface of the boom as well as

the back of the mounting bracket with the 3M VHB wipes and then stick the bracket onto the boom.

If you are using a secondary mounting plate between the sensor bracket and the machine, screw the

bracket onto the plate and follow the same process as above.

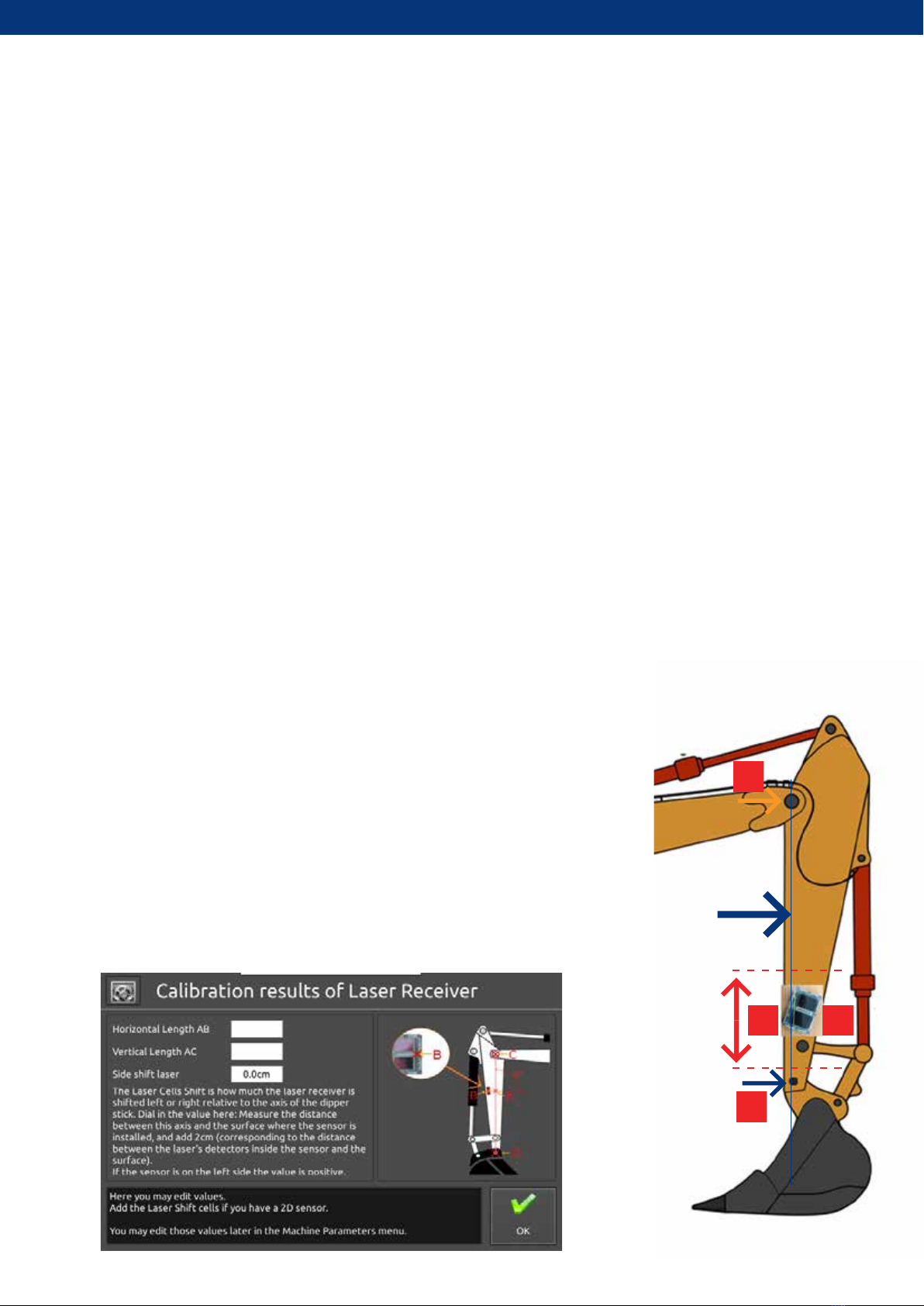

Recommended Installation method of dipper sensor in conjunction with Laser

catch calibration.

Using a magnetic plumb bob or a string line and magnets, create a line

that is between the centre points of the dipper stick pivot pin and the

bucket pivot pin.

In the bottom 1/3 of the dipper arm, place the sensor on a point so that

the very centre of the laser receiver is on this line, rotate the sensor

forward (away from the cab) slightly by 10-15°.

Take a measurement from the centre of the top pin to the centre of the

sensor, this will be the A-C measurement. The A-B Measurement will be 0.

Enter these measurements via the System Settings menu once the main

iDig calibration steps are complete.

A B

C

D