3

SAFETY RULES

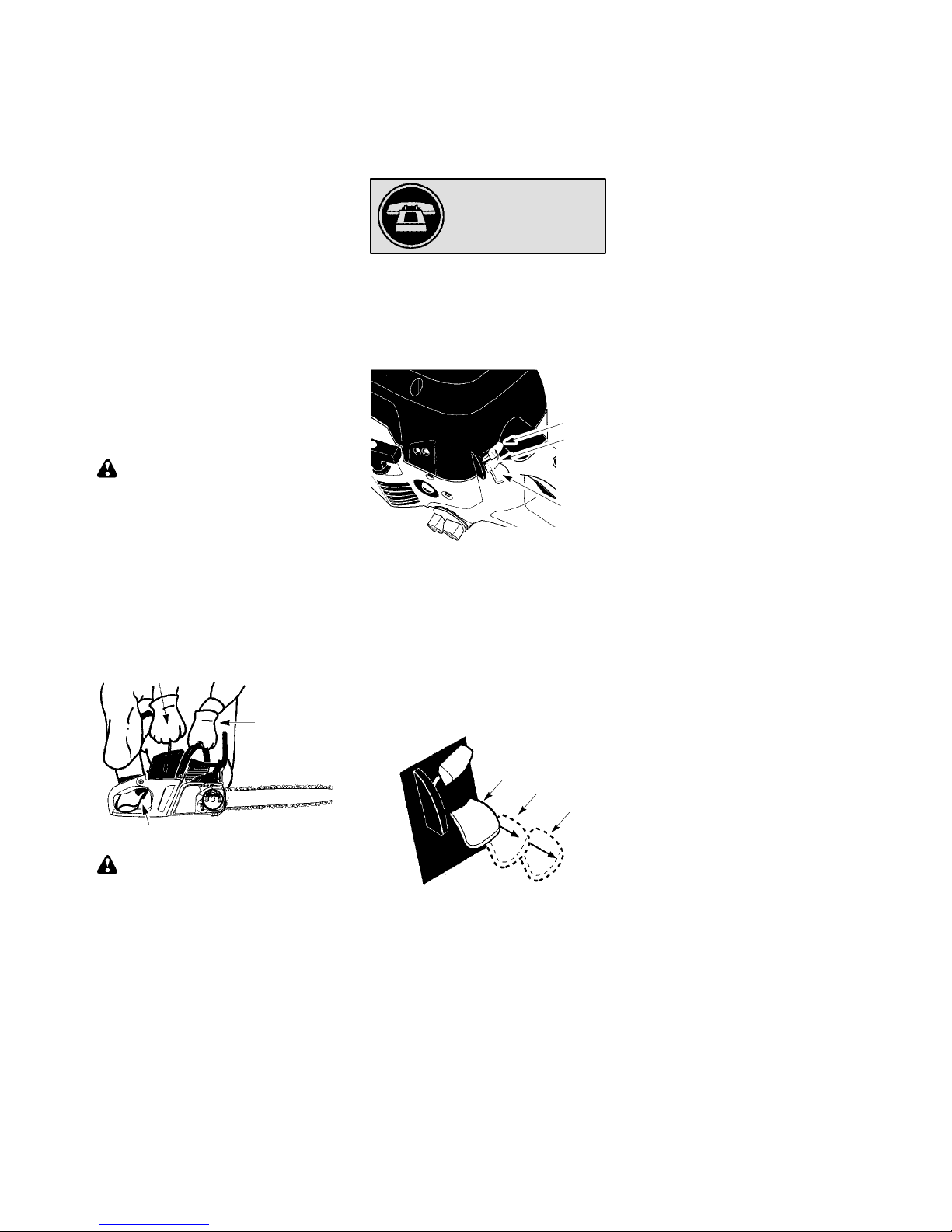

WARNING: Always disconnect

spark plug wire and place wire where it can-

not contact spark plug to prevent accidental

starting when setting up, transporting, ad-

justing or making repairs except carburetor

adjustments.

Because a chain saw is a high-speed wood-

cutting tool, special safety precautions must

be observed to reduce the risk of accidents.

Careless or improper use of this tool can

cause serious injury.

PLAN AHEAD

SRead this manual carefully until you com-

pletely understand and can follow all safety

rules, precautions, and operating instruc-

tions before attempting to use the unit.

SRestrict the use of your saw to adult users

who understand and can follow safety

rules, precautions, and operating instruc-

tions found in this manual.

SWear protective gear. Always use steel-toed

safety footwear with non-slip soles; snug-fit-

ting clothing; heavy-duty, non-slip gloves;

eye protection such as non-fogging, vented

goggles or face screen; an approved safety

hard hat; and sound barriers (ear plugs or

mufflers) to protect your hearing. Regular

users should have hearing checked regular-

ly as chain saw noise can damage hearing.

Secure hair above shoulder length.

Snug

Fitting

Clothing

Safety

Shoes Safety Chaps

Heavy Duty

Gloves

Eye

Protection

Hearing

Protection

Safety Hat

SKeep all parts of your body away from the

chain when the engine is running.

SKeep children, bystanders, and animals a

minimum of 30 feet (10 meters) away from

the work area. Do not allow other people

or animals to be near the chain saw when

starting or operating the chain saw.

SDo not handle or operate a chain saw when

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. You

must be in good physical condition and men-

tally alert. Chain saw work is strenuous. If

you have any condition that might be aggra-

vated by strenuous work, check with your

doctor before operating a chain saw.

SCarefully plan your sawing operation in ad-

vance. Do not start cutting until you have a

clear work area, secure footing, and, if you

are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

SDo not operate a chain saw with one hand.

Serious injury to the operator, helpers, by-

standers or any combination of these per-

sons may result from one-handed operation.

A chain saw is intended for two-handed use.

SOperate the chain saw only in a well-venti-

lated outdoor area.

SDo not operate saw from a ladder or in a tree.

SMake sure the chain will not make contact

with any object while starting the engine.

Never try to start the saw when the guide

bar is in a cut.

SDo not put pressure on the saw at the end of

the cut. Applying pressure can cause you to

lose control when the cut is completed.

SStop the engine before setting the saw

down.

SDo not operate a chain saw that is dam-

aged, improperly adjusted, or not com-

pletely and securely assembled. Always

replace bar, chain, hand guard, or chain

brake immediately if it becomes damaged,

broken or is otherwise removed.

SWith the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the

rear, preferably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

SHave all chain saw service performed by a

qualified service dealer with the exception

of the items listed in the maintenance sec-

tion of this manual. For example, if improp-

er tools are used to remove or hold the fly-

wheel when servicing the clutch, structural

damage to the flywheel can occur and

cause the flywheel to burst.

SMake certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR AD-

JUSTMENT.

SNever modify your saw in any way.

SKeep the handles dry, clean, and free of oil

or fuel mixture.

SKeep fuel and oil caps, screws, and fas-

teners securely tightened.

SUse only Poulan PRO accessories and re-

placement parts as recommended.

HANDLE FUEL WITH CAUTION

SDo not smoke while handling fuel or while

operating the saw.

SEliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

There should be no smoking, open flames,

or work that could cause sparks. Allow en-

gine to cool before refueling.

SMix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills before starting saw.

SMove at least 10 feet (3 meters) from fuel-

ing site before starting engine.

STurn the engine off and let saw cool in a

non-combustible area, not on dry leaves,