8

11

WARNING: RISK OF PERSONAL INJURY.

Always disconnect tool from power source

before making any adjustments, installing

or changing accessories.

To Adjust the Miter Angle

1. (SEE FIGURE 7) The miter angle of a cut may

be adjusted 0 - 45° to the right or left. To do

so, loosen the miter lock knob (1) located at

the front of the table.

2. Move the handle to the right or left until the

desired miter angle of cut is indicated by the

miter scale (2) located on the base. Then, tighten

the handle to lock the miter Angle in place.

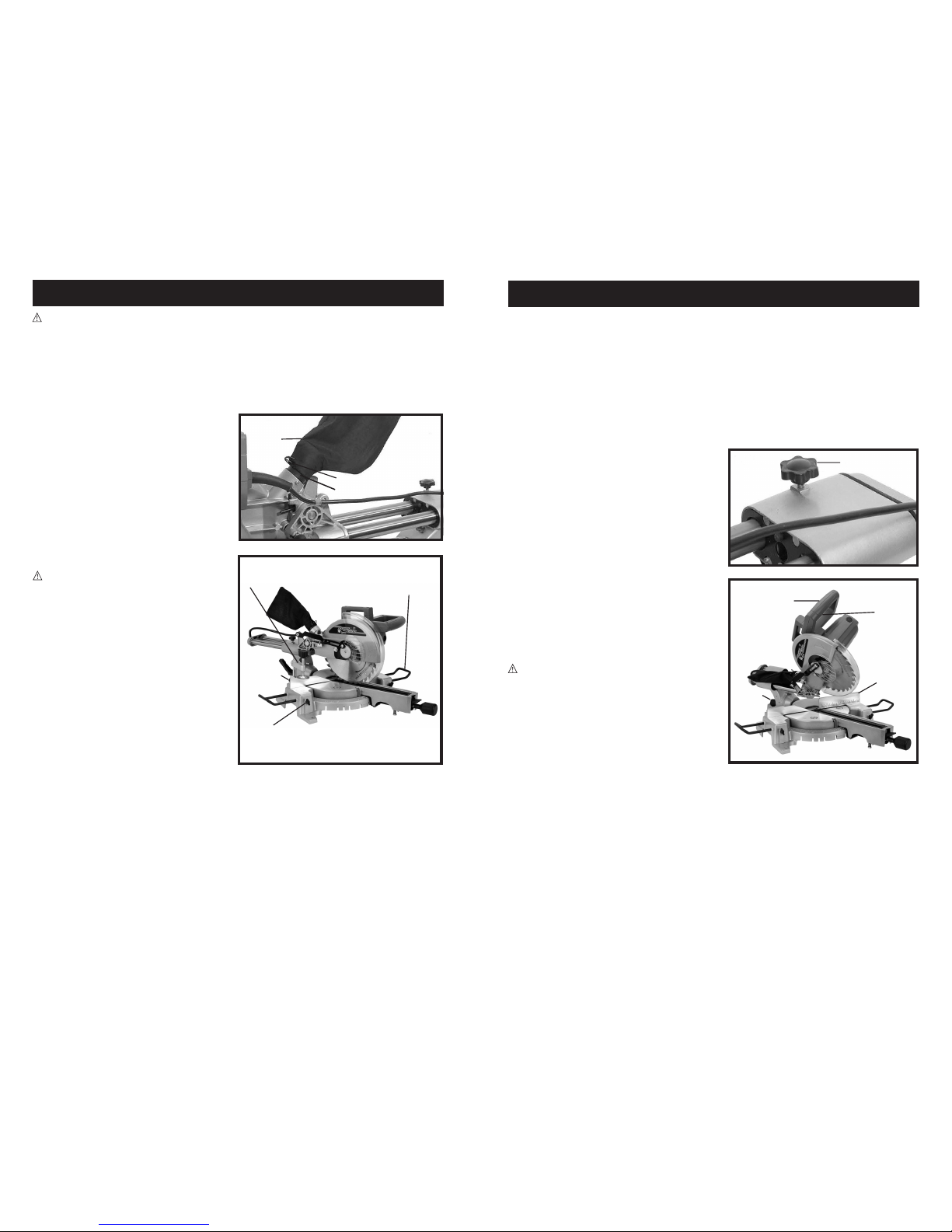

Unlocking Saw Cutting Arm

NOTE: The unit is packaged with the saw arm

in the lock down position.

1. Press down on the control handle enough to

take spring tension off of the lock down pin (1).

2. (See Figure 5) While holding down the control

handle, pull out on the lock down pin to

release the saw arm (2). Turn the pin

90 degrees to rest in the unlocked

(shallow slot) position.

3. Slowly let the saw arm rise to the

upright position.

Locking Cutting Arm in the Down Position

1. Press downward on control handle and lower the saw arm.

2. (See Figure 5) With arm down, pull out and turn the lock pin (1) 90 degrees to the locked

(deep slot) position.

3. Release the pin allowing it to engage the saw arm.

CAUTION: When carrying you miter saw or transporting it from one location to another, the saw

cutting arm should be locked in the down position and the saw should be carried by the handle.

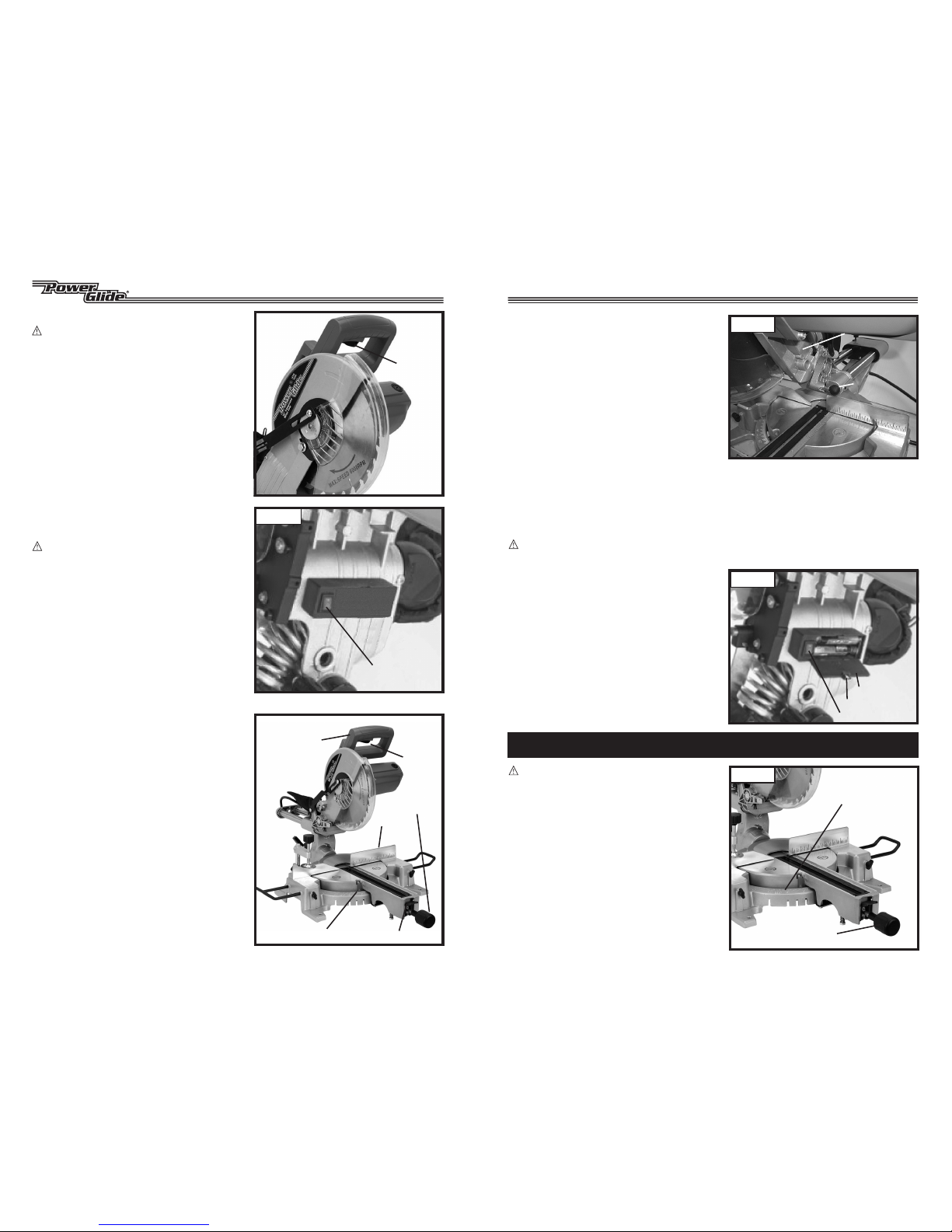

Installing the Laser Batteries (Figure 6)

1. Turn the On/Off rocker switch (1) to the

off “O” position.

2. Remove the battery cover Phillips head

screw (2). Lift and remove the battery

cover (3), rear (screw end) first.

3. Insert new "AAA" size alkaline type

batteries (4), paying attention to proper

polarity (+ / -) installation direction.

4. Replace the battery cover and screw.

Figure 5

(1) Lock Down Pin

(2) Saw Arm

Figure 6

(1) Rocker Switch

(2) Phillip Head Screw

(3) Battery Cover

ADJUSTMENTS

(1) Miter Lock Knob

(2) Miter Scale

Figure 7

The On/Off Trigger Switch

CAUTION: Before plugging in the Miter Saw,

check the operation of the Trigger (1). Do not

operate the miter saw if the trigger is not

operating properly.

1. (SEE FIGURE 11) To start on the miter saw,

simply squeeze the On/Off trigger switch (1).

2. To stop the tool, release pressure on the

On/Off trigger switch.

Laser Aided Sighting (Figure12)

1. To activate the laser-sighting guide, move the

rocker switch (1) to the on “I” position. The

laser will project a narrow beam of red light

in line with the saw blade.

2. Align the light beam with the marked cut line

on the work piece.

3. To turn off the laser cutting guide, move the

rocker switch to the off “O” position.

CAUTION: LASER RADIATION - Do not stare

into the beam. Use of controls or adjustments

or performance of procedures other than

those specified in this instruction manual

may result in hazardous radiation exposure.

1. Laser radiations on work table - Do not stare

into reflected light from work surface.

2. Avoid exposure - Laser light is emitted from

the housing front aperture. Do not stare into

the aperture.

3. Do not disassemble laser.

4. Operate laser only when cutting. Turn laser

off after use.

Making a Miter Cut

1. (See Figure 13) Raise the control handle (1)

up to allow positioning of the workpiece.

2. Loosen the miter locking knob (2), press down

on the miter thumb lever (3) and rotate the

cutting arm until the miter table pointer aligns

with the desired angle on the scale. Tighten the

miter locking knob.

3. Grasp the workpiece firmly with one hand and

secure it flat on the miter table with one edge

securely against the fence (5). Turn on the

laser-sighting guide. Adjust the workpiece to

align the cut-line with the Red laser beam

or saw blade. Use the material clamp

when possible.

CAUTION: When cutting a large workpiece,

make sure its entire length is properly

supported. If necessary, use a roller stand

(not included) with a larger workpiece.

Figure 11

Figure 13

Figure 12

(1) Trigger

(1) Rocker Switch

(2) Miter Lock Knob

(1) Control Handle

(5) Fence

(6) Trigger

Switch

(3) Miter Thumb Lever

(4) Miter Table Pointer