11 4

7. Disconnect power before changing blade or servicing.

8. To reduce risk of injury, return carriage to the full rear position after each crosscut operation.

9. Release lower guard retraction mechanism after each cut and before moving or removing the

work piece. Blade adjustment is to be made with the power off and the blade stopped.

10. Return all guards to original position if any are moved during blade replacement. Check all

guards for proper operation after service.

11. The lock down pin is to be used only to lock the head in place for carrying and storage. It is

not to be used for any cutting operation.

12. DO NOT OPERATE WITH ANY GUARD DISABlED, DAMAGED, OR REMOVED. Moving guards must

move freely and close instantly.

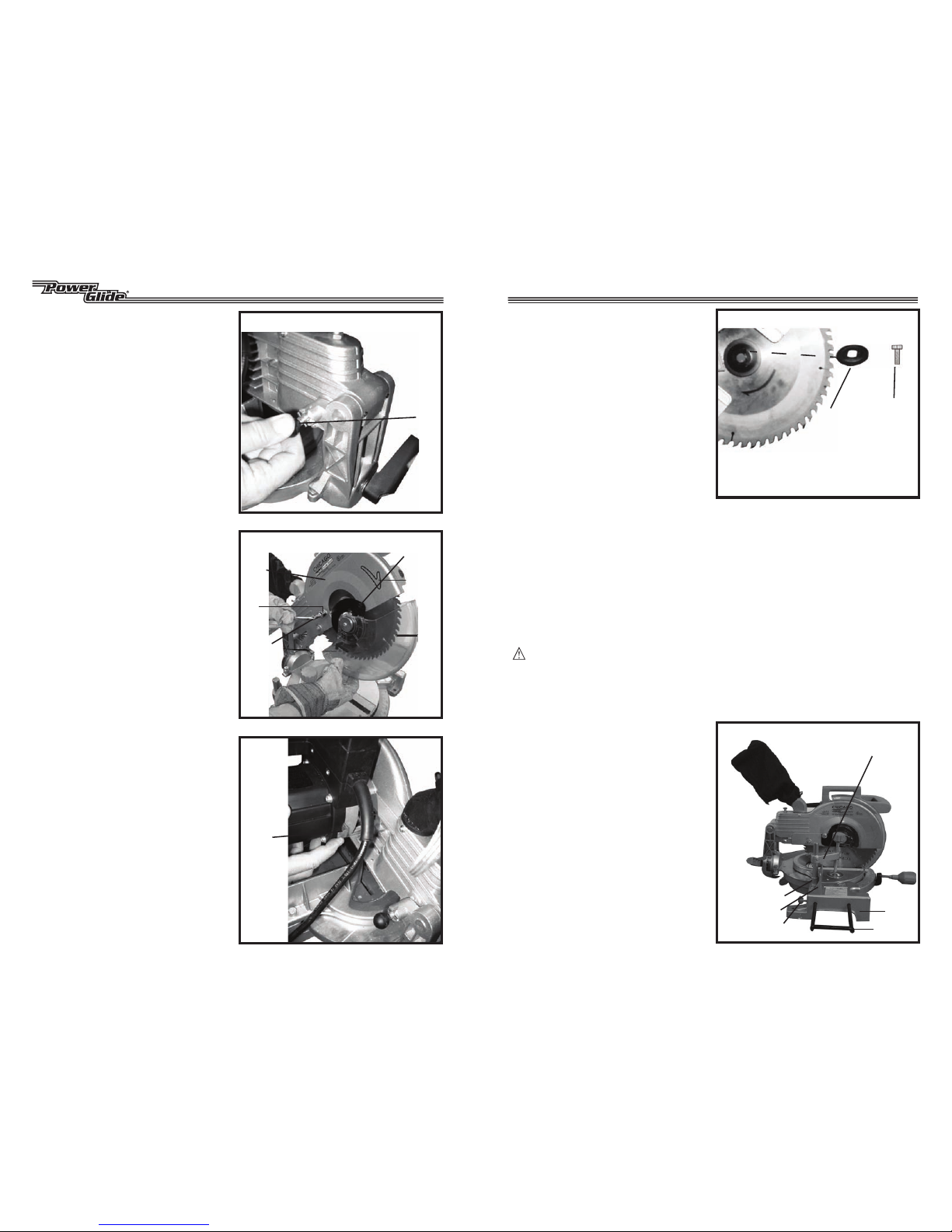

13. Replacing the Saw Blade only with a new blade with a diameter of 10”, an RPM rating of at

least 5,300, and a 5/8” arbor hole.

14. To avoid accidental injury, always wear heavy duty work gloves when changing Saw Blade.

15. Before use, make sure the Saw Blade is properly mounted on the Saw Spindle. Make sure the

Saw Blade is balanced, and is not cracked or bent.

16. The Saw Blade will become hot while cutting. Allow the Saw Blade to completely cool before

touching.

17. Make sure the workpiece is free from nails and any other foreign objects which can damage

the Saw Blade.

18. The Cross Pin (28) should always be in the “locked down” position when the Saw is not being

used and when the Saw is being transported. The Cross Pin should be activated in the “locked

up” position when changing Saw Blades. NEVER use the Cross Pin in any cutting operation.

The Cross Pin allows the operator to lock the Saw Blade in position, preventing the Saw Blade

from being raised or lowered.

19. Allow the Saw Blade to spin up to full speed before feeding it into the workpiece. Do not force

the Saw Blade into the workpiece when cutting. Apply moderate pressure, allowing the Saw

Blade to cut without being forced. When turning off the Saw, allow the Saw Blade to spin

down and stop on its own. Do not press against the Saw Blade to stop it.

20. Industrial applications must follow OSHA requirements.

21. Proper Miter Saw location: Make sure the Miter Saw is located on a flat, level, sturdy surface

capable of supporting the weight of the Miter Saw, workpieces, and all other tools and

accessories.

22. Never attempt to remove material stuck in the moving parts of the Miter Saw while the

machine is plugged in and running.

23. The use of accessories or attachments not recommended by the manufacturer may result in a

risk of injury to persons.

24. When servicing use only identicalreplacement parts.

25. Only use safety equipment that has been approved by an appropriate standards agency.

Unapproved safety equipment may not provide adequate protection. Eye protection must be

ANSI-approved and breathing protection must be NIOSH-ap-proved for the specific hazards in

the work area.

26. Industrial applications must follow OSHA guidelines.

27. Maintain labels and nameplates on the tool. These carry important safety information. If

unreadable or missing, contact Harbor Freight Tools for a replacement.

28. Avoid unintentional starting. Prepare to begin work before turning on the tool.

29. People with pacemakers should consult their physician(s) before use. Electromagnetic fields

in close proximity to heart pacemaker could cause pacemaker interference or pacemaker

failure.

BASIC OPERATION

WARNING: Make sure the Power Cord (102) of the Miter Saw is unplugged from its lectrical

outlet. Then, if necessary, make adjustments to the workpiece Holder (9), cutting depth, miter

angle, and bevel angle.

1. Raise the Saw Blade (56) up to allow positioning of the workpiece.

2. Check to make sure the Trigger (98) is operating properly.

3. Place the workpiece on the Table (18a) and against the Guide Fence (37a).

4. Use the Clamp Assembly (36) to hold the workpiece in place.

5. Plug the Power Cord (102) into the nearest 120 volt, grounded, electrical outlet.

6. Squeeze the Trigger (98) to turn on the Miter Saw.

7. When the Saw Blade (56) is turning at full speed, slowly bring down the Motor Housing (75) to

complete the cut.

Note: Feed the Saw Blade into the workpiece gradually. Do not force the machine to

remove material faster than it was designed to cut.

8. When cutting a large workpiece, make sure its entire length is properly supported. If

necessary, use a roller stand (not included) with a larger workpiece.

9. Never attempt to remove material stuck in the moving parts of the Miter Saw while it is

plugged in and running.

10. Turn off the Miter Saw if the workpiece is to be backed out of an uncompleted cut.

11. When the cut is complete, release the Trigger (98) to turn off the Miter Saw.

12. Wait until the Saw Blade (56) comes to a complete stop. Raise the Motor Housing (75). Then,

unplug the Power Cord (102) from its electrical outlet.

13. Loosen the Clamp Assembly (36), and remove the workpiece and scrap material from the Table

(18a).

INSPECTION, MAINTENANCE AND CLEANING

WARNING: Always make sure the Trigger (98) is in its “OFF” position, and unplug the Power

Cord (102) from its 120 volt electrical outlet before performing any inspection, adjustments,

maintenance, or cleaning.

Make sure the power tool is cool to the touch before inspection, maintenance, and cleaning

begin. Always protect your hands by wearing work gloves.

1. Before each use, inspect the general condition of the Miter Saw. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, damaged electrical wiring,

loose, cracked, or bent Saw Blade (56), and any other condition that may affect its safe

operation. If abnormal noise or vibration occurs, have the problem corrected before further

use. Do not use damaged equipment. Never work with a dull saw blade.

2. Daily: With a soft brush, cloth, or vacuum, remove all dust and debris from the Miter Saw.

Then, use a premium quality, lightweight machine oil to lubricate all moving parts except

the Saw Blade (56).