FUNCTIONAL

DESCRIPTION

AReciprocating Saw

BMetal Blade

CWood Blade

DSpeedAdjustment

E On / Off Switch

F Locking Switch

1

2

1

Hex Key

1.

Use the speed control wheel (1) to vary the saws speed from

300 to 3,000 strokes per minute. Rotate the wheel forward,

toward the number "1" for slower speed and backward

toward the number "6" for higher speeds. Full speed is

obtained when the switch is in "MAX" position.

Caution:

• Do not force the speed adjustment knob beyond its minimum

and maximum range "1" or "MAX". Damage to the tool could

result.

• Do not operate the saw at low speed 1 or 2 for prolonged

periods. Low speed can produce high loads on the motor and

can cause overheating or damage.

Note:

• Optimum blade speed is determined by the work piece,type

and condition of saw blade. Generally:slow speeds are

used for hard materials like iron or steel and precision work

in delicate materials, while higher speeds are best in soft

materials like wood or sheet rock and will produce rapid

material removal and lower blade life.

1. Speed Control Wheel

1. Screws

2. Shoe

1. Loosen the two socket head screws (1) with the hex key

provided.

2. Position the shoe (2) in the desired location and tighten the

hex screws to secure.

Note:

• Position the shoe fore or aft to vary the depth of cut or as the

blade looses its cutting ability in a particular spot.

Extension Cords

1. Make sure your extension cord is in good condition. When using an extension cord,be sure to

use one heavy enough to carry the current your product will draw.An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating.Table 1 shows the

Correct size to use depending on cord length and nameplateAmpere rating. If in doubt,use the

next heaver gage.The smaller the gage number, the heaver the cord.

2. Outdoor Use Extension Cords. When tool is used outdoors,use only extension cords intended

for use outdoors and so marked.

3. Use only UL listed extension cords. Inspect extension cord before use and never use damaged

or altered extension cords. Follow extension cord manufacturer safety instruction.

DANGER:

Double insulated tools are equipped with a polarized plug (one blade is wider than the other).This

plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit,contact a qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for the three wire grounded power cord

and grounded power supply system.

SPECIFIC SAFETY RULES

1.Hold tool by insulated gripping surfaces when performing an operation where the cutting tool

may contact hidden wiring. Contact with a "live" wire will also make exposed metal parts of the

tool "live" and shock the operator.

2. Always keep hands and body away from saw blade at all times during operation. Never reach

underneath or behind the work piece while cutting. Never hold the work piece being cut in your

hands,on your legs or feet.

3. Keep the shoe plate of saw firmly in contact with the cutting material at all times.

4. Never cut material thicker than the retracted length of the blade

5. Inspect for and remove any screws,staples, nails or other foreign objects before cutting.

6. Check that there is enough space under and behind the work piece for the reciprocating blade.

Be sure you will not be cutting through any electrical wires,plumbing, nails or your workbench.

SYMBOLS

The following symbols are used for the tool:

V ............Volts

Amp........Amperes

~...........Alternating Current

.........Double Insulted

HZ...........Hertz

SPM........Strokes per minute

Minimum Recommended Extension Cord Gauge (AWG) Chart (Table 1)

AMP Load Volts Extension Cord Length

120V 25' 50' 100' 150'

AWG

1-5 18 16 16 14

6-10 18 16 14 12

10-12 14 14 14 12

12-16 14 12

Not recommend

Table 1

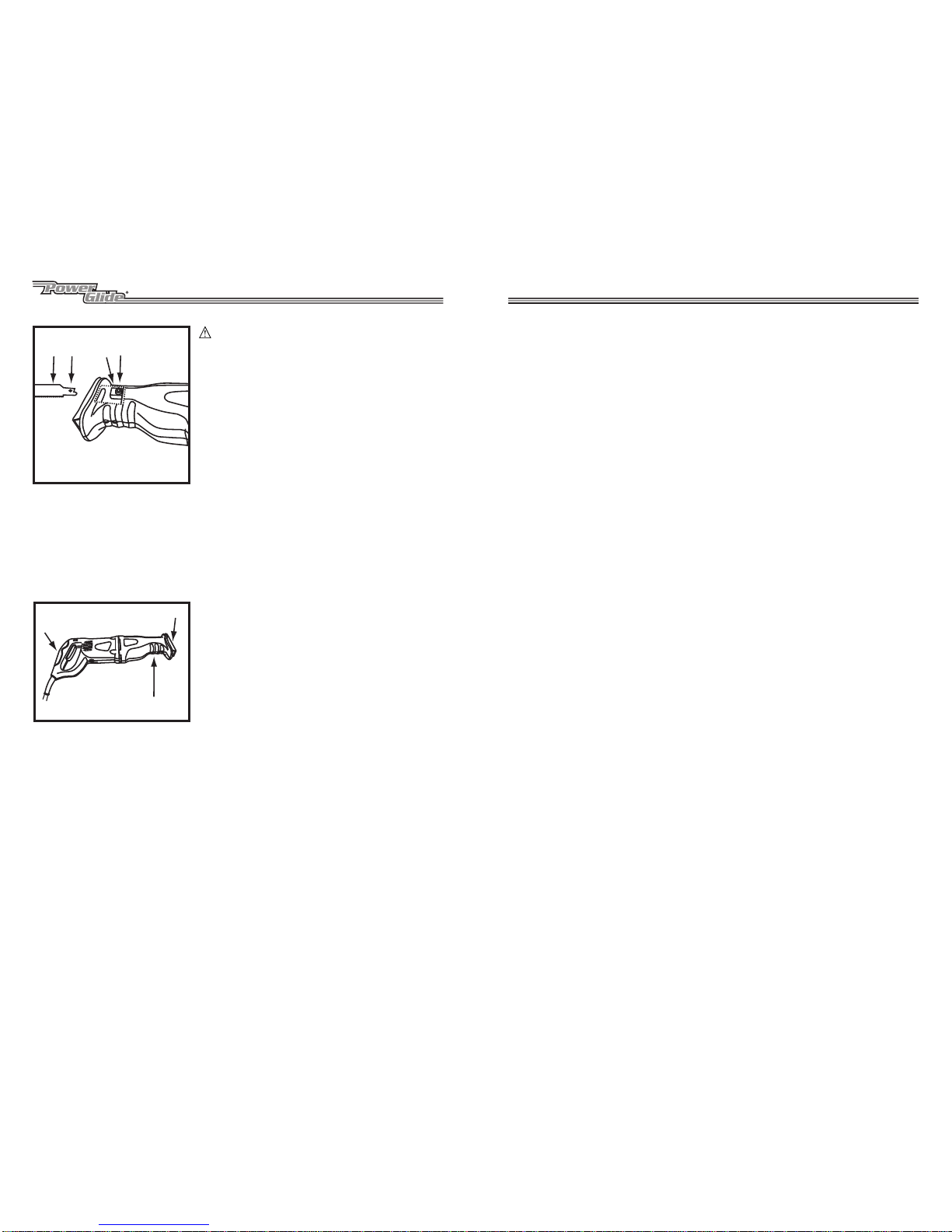

Fig. 1

1. Safety Button

2. On/Off Trigger Switch

On / Off Switch (Fig. 1)

1. To start the saw,depress the safety switch (1) and pull the On-Off trigger switch (2). To stop,release the trigger switch.

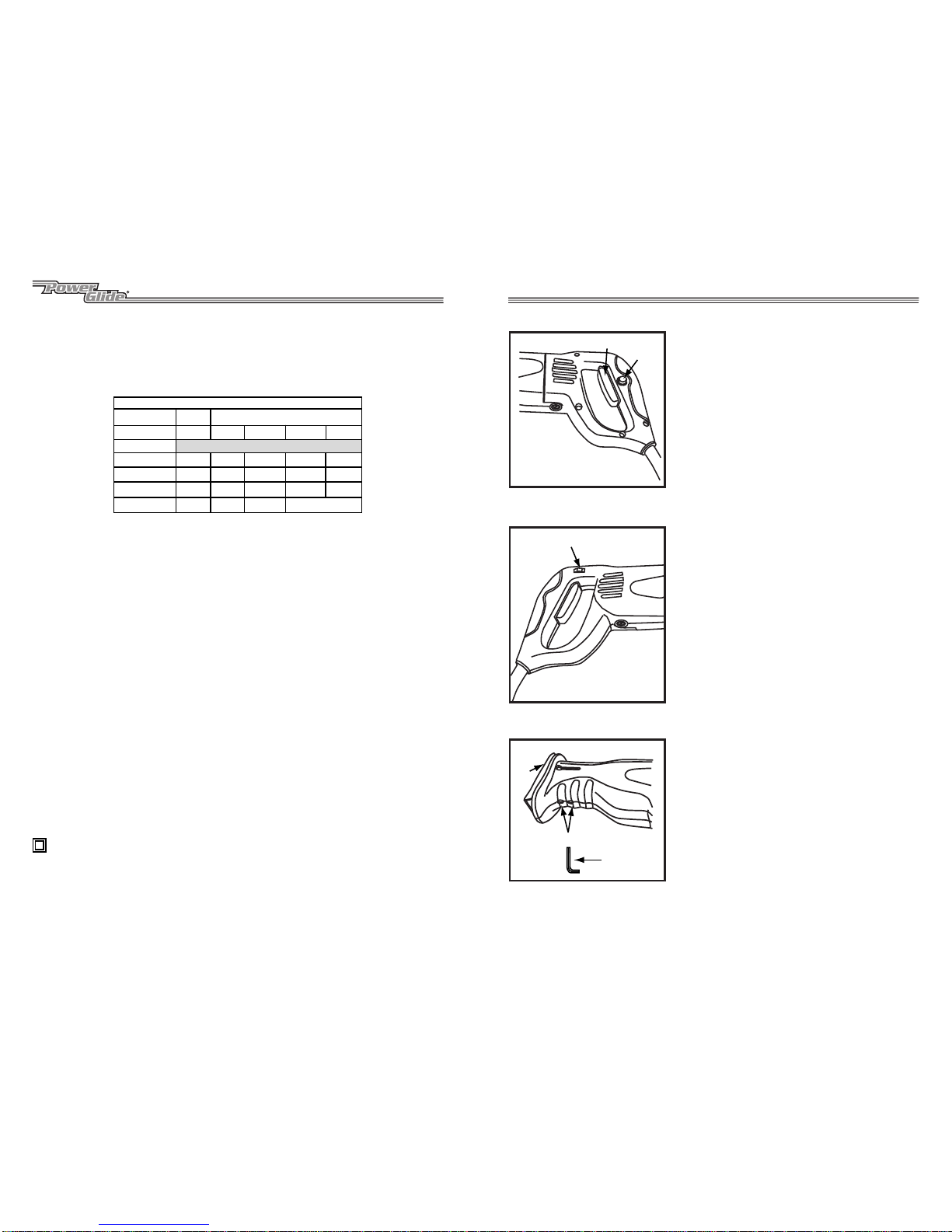

Fig. 2

1. Speed Control Wheel

Speed adjustment (Fig. 2)

1. Use the speed control wheel (1) to vary the saws speed from 300 to 3,000 strokes per minute. Rotate the wheel forward,toward the number "1" for slower speed and backward toward the number "6" for higher speeds. Full speed is obtained when the switch is in "MAX" position.

Caution:

* Do not force the speed adjustment knob beyond its minimum and maximum range "1" or "MAX". Damage to the tool could result.

* Do not operate the saw at low speed 1 or 2 for prolonged periods. Low speed can produce high loads on the motor and can cause overheating or damage.

Note:

* Optimum blade speed with is determined by the work piece, type and condition of saw blade. Generally:slow speeds are used for hard materials like iron or steel and precision work in delicate materials, while higher speeds are best in soft materials like wood or sheet rock and will produce rapid material removal and lower blade life.

Fig. 3

1. Screws

2. Shoe

Adjusting the shoe (Fig. 3)

1. Loosen the two socket head screws (1) with the hex key provided.

2. Position the shoe (2) in the desired location and tighten the hex screws to secure.

Note:

* Position the shoe fore or aft to vary the depth of cut or as the blade looses its cutting ability in a particular spot.

1. To start the saw, depress the safety switch (1) and pull the

On-Off trigger switch (2).To stop,release the trigger switch.

On / Off Switch (Figure 1)

1. Safety Button

2. On/Off Trigger Switch

FIGURE 1

FIGURE 2

FIGURE 3

Speed Adjustment (Figure 2)

Adjusting The Shoe (Figure 3)

WARNING:

•Dust and debris created during sawing,drilling,grinding or sanding on some materials may

contain chemicals known to the State of California to cause cancer or birth defects or other

reproductive harm.To reduce exposure to these chemicals,always use approved safety

equipment,work in a well-ventilated area and wear dusk mask that filters out microscopic

particles.

1

2