3.

Battery Storage

High temperature or poor ventilation during storage and delivery will result high self-discharge rate.

Therefore, it is important to maintaining good ventilation and keeping away from fire, flame, water and

heat supply etc.

When storing the battery (not charging), disconnect from charger and load.

Store the batteries in a dry, clean and preferably cool location.

The batteries are supplied charged, however during storage it is advisable not to store batteries for

more than the time specified below without a supplementary recharge:

a) Six months at 20° C / 68o F

b) Three months at 30° C / 86o F

c) Six weeks at 40° C / 104o F

d) Do not store over 40° C / 104o F

A supplementary charge is required to maintain the batteries stored for some period over advised time

limit from above. For detailed charging procedures, please refer to section 6.1 Supplementary Charge.

Failure to observe charging conditions may result in greatly reduced capacity and service life and limit

warranty of batteries.

4.

Battery System Installation Considerations:

No fire, flame or heat supply should be near the battery;

Avoid installation near heat supply or in direct sunlight;

Avoid operating in humid / damp locations;

Do not operate in sealed enclosed or without ventilation.

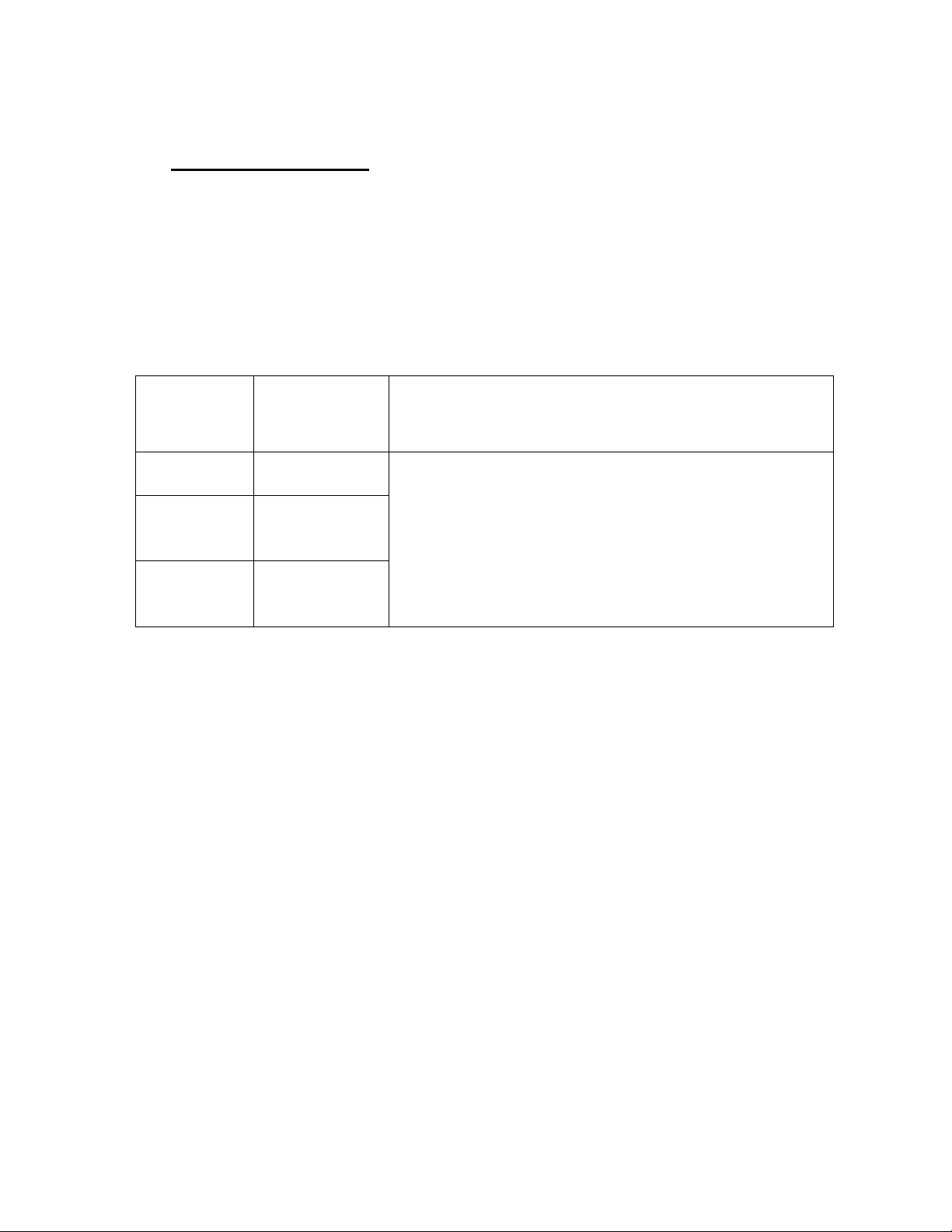

Temperature Range UL94-V0 Flame Retardant Jars

Charging -4°F ~ +131°F (-20°C ~ +55°C)

Discharging +32°F ~ 122°F (0°C ~ +50°C)

Storage -4°F ~ +131°F (-20°C ~ +55°C)

Parallel Connections Recommended within 4 groups.

Heat Dispersing Maintain 0.4 to .79” (10 to 20mm) inter-bloc distance between batteries.

Multilayer Installation Temperature of each layer should be controlled within 3°C.

Ventilation Ensure batteries are stored and used in ventilated conditions.

Optimum Ambient Temp. 72°F to 78°F (23°C to 26°C)

Float Charge (25°C) Limited current ≤0.30C10, voltage 2.23~2.30V/cell

Cyclic Charge (25°C) Limited current ≤0.30C10, voltage 2.30~2.40V/cell

Mixing Batteries Do not mix new and old batteries, batteries of different capacity or manufacturers.

If required, please consult with Power Storage Solutions technical support.

pg.4