This

1

1

2

3

4

2

3

4

NOTE! This page refers to parts not included in all packages.

- 16 -

CARE AND ENVIRONMENT ASSEMBLE A SCROLL SAW

These instructions should be read in

conjunction with those for the case used.

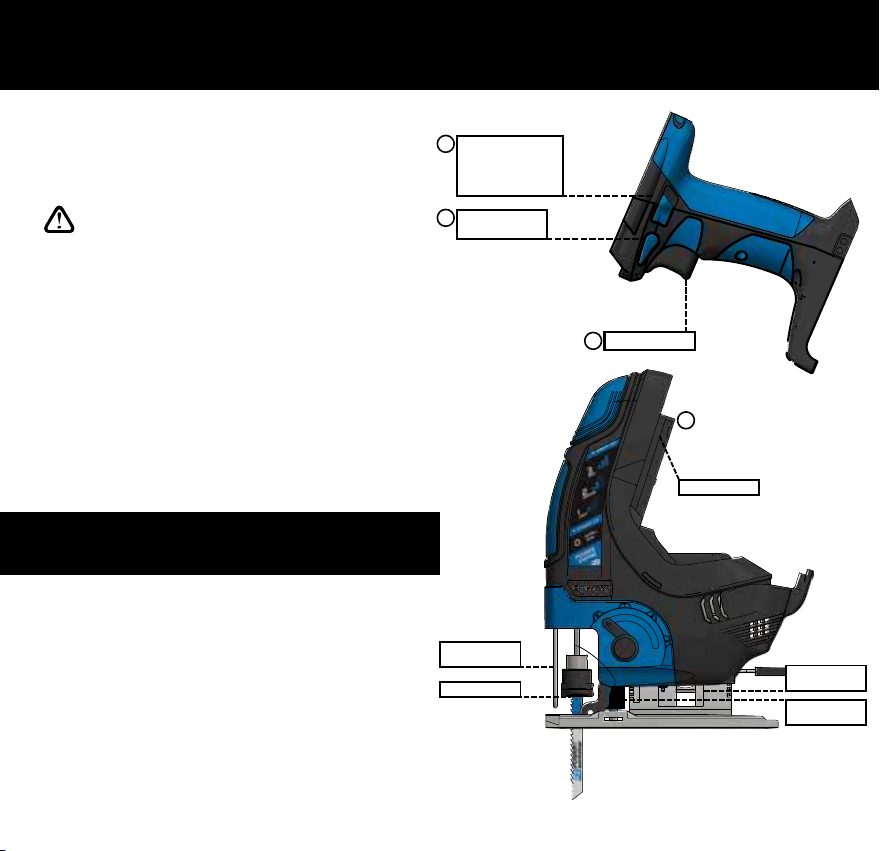

Fit the Jigsaw to the Case Lid

Open the case lid and

remove any tted tools.

Slide the Locking Slider

out of the way. Fit the rear

of the Sole Plate into the

recess at the bottom of the

opening in the case lid and

the blade through the

small slot in the case lid.

Rotate the saw into place

and release the Locking

Slider, ensure it slides

back to hold the saw in

place securely.

General inspection

Regularly check that all the xing screws are present and

tight, they may vibrate loose over time. Keep the tool’s air

vents unclogged and clean at all times.Remove dust and

dirt regularly.Cleaning is best done with compressed air or

a rag.

CAUTION, Do not use cleaning agents to clean the

plastic parts of the tool. A mild detergent on a damp cloth

is recommended. Water must never come into contact

with the tool.After each use, carefully clean the tool with

a brush or rag.Clear any debris from around the battery

mount, moving parts and clips.

Lubrication

No internal lubrication is necessary, the bearing area is

sealed. A coating of machine oil on the metal parts will

help prevent corrosion.

Storage

Store the tool, instruction manual and accessories in a

secure, dry place.In this way you will always have all the

information and parts ready to hand. Lithium ion batteries

should ideally be stored with 40 to 80% capacity between

10ºC and 20ºC (50ºF and 68ºF).

WARNING! Always charge Li-ion batteries before storage

and at least every 3 months to prevent permanent

damage.

Environment

When the time comes to dispose of this product please

consider the environment and take it to a recognised

recycling facility instead of disposing with general

household waste.

Call your local council, civic amenity site, or recycling

centre forinformation on the recycling and disposal of

electrical products andbatteries. If you do not have access

to suitable disposal facilities in your area please contact

your place of purchase, they will advise you on the best

way to dispose of your product.

Maintenance

All electrical parts should be regularly serviced by an

approved engineer.

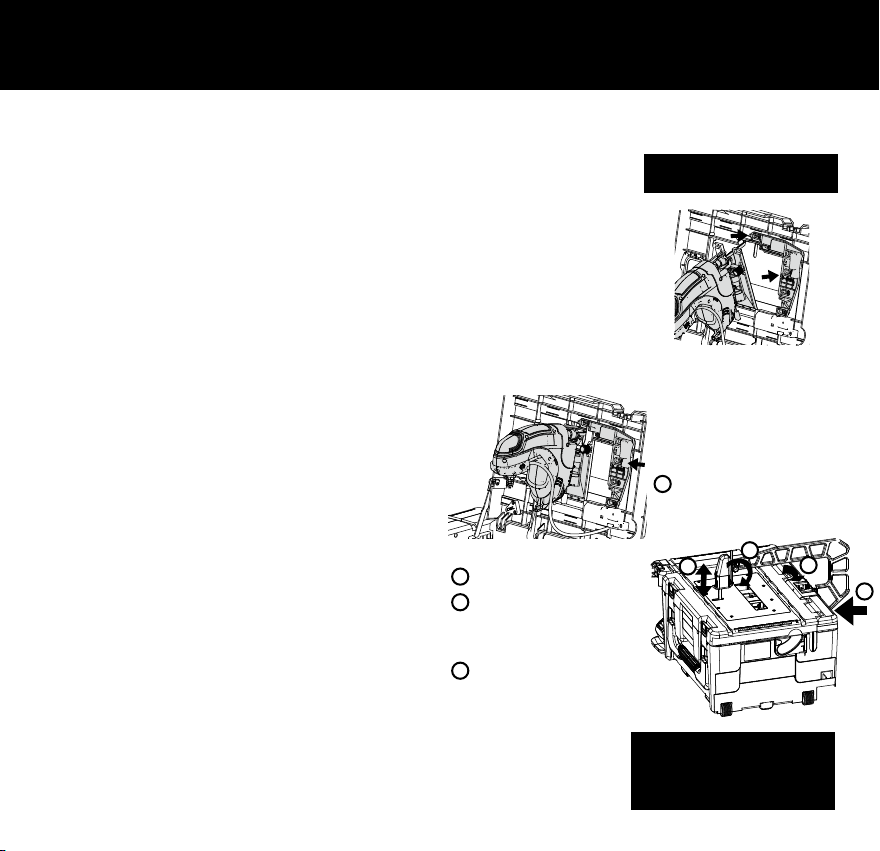

Fit the Internal Power

Coupling onto the Rails on

the saw in where the Unigrip

connects for handheld use.

Set Blade Angle then close

and latch the lid.

Insert the Scroll Saw

Guide horizontally into the

rear of the case.

Close the lock latch,

adjust the transparent

blade shield up or down

to t dient thickness or

wood piece,

turn the knob to lock

the shield in position.

START / STOP

Use the GREEN (start) and RED (stop)

buttons to start or stop the tools tted in

the case.