VOLTAGE – Continued 7

FULLY CHARGED VOLTAGE READINGS On-charge voltage readings are most

informative and are good indicators of battery condition. These readings should be

taken when the battery is approaching full charge with 2% of the battery capacity

flowing into the battery. New batteries, when fully charged and 2% of the battery

capacity flowing into the battery, will have cell voltages between 2.55 – 2.65 vpc.

Older batteries with the same circumstances will have voltages about 2.45 – 2.55 vpc.

Multiplying the battery capacity times .02 will give you 2% of capacity.

Example: 6-85F-17S 845 x .02 = 16.9 amps.

VARIATIONS IN ON-CHARGE VOLTAGE If all cells of a battery show similar full-

charge voltages, they are equally healthy. The uniformity and value of the individual

cell voltage readings vary with the overall condition of the battery. A battery with an on-

charge voltage of 2.45 to 2.50 volts per cell has more uniformly healthy cells than a

battery having an on-charge voltage spread of 2.40 to 2.50 volts per cell. The battery’s

age and service duty must be considered in the interpretation of the on-charge voltage

readings. An example would be an older battery which has on-charge cell voltage

readings of 2.45 volts to 2.65 volts. The reason may very well be that the inside cells

operate at higher than average temperatures causing higher local action, which would

result in lower voltage. Regular equalize charging will compensate for the higher self-

loss of the inside cell. Any wide spread in on-charge voltage that could not be

attributed to the battery’s service life or age is a sign that something is wrong and

attention is necessary. Some cause of abnormally wide spread or charge voltages are:

1. Abnormal temperature differential

2. Internal shorts

3. Acid loss causing over-discharge

4. Insufficient charging

5. Insufficient equalize charging

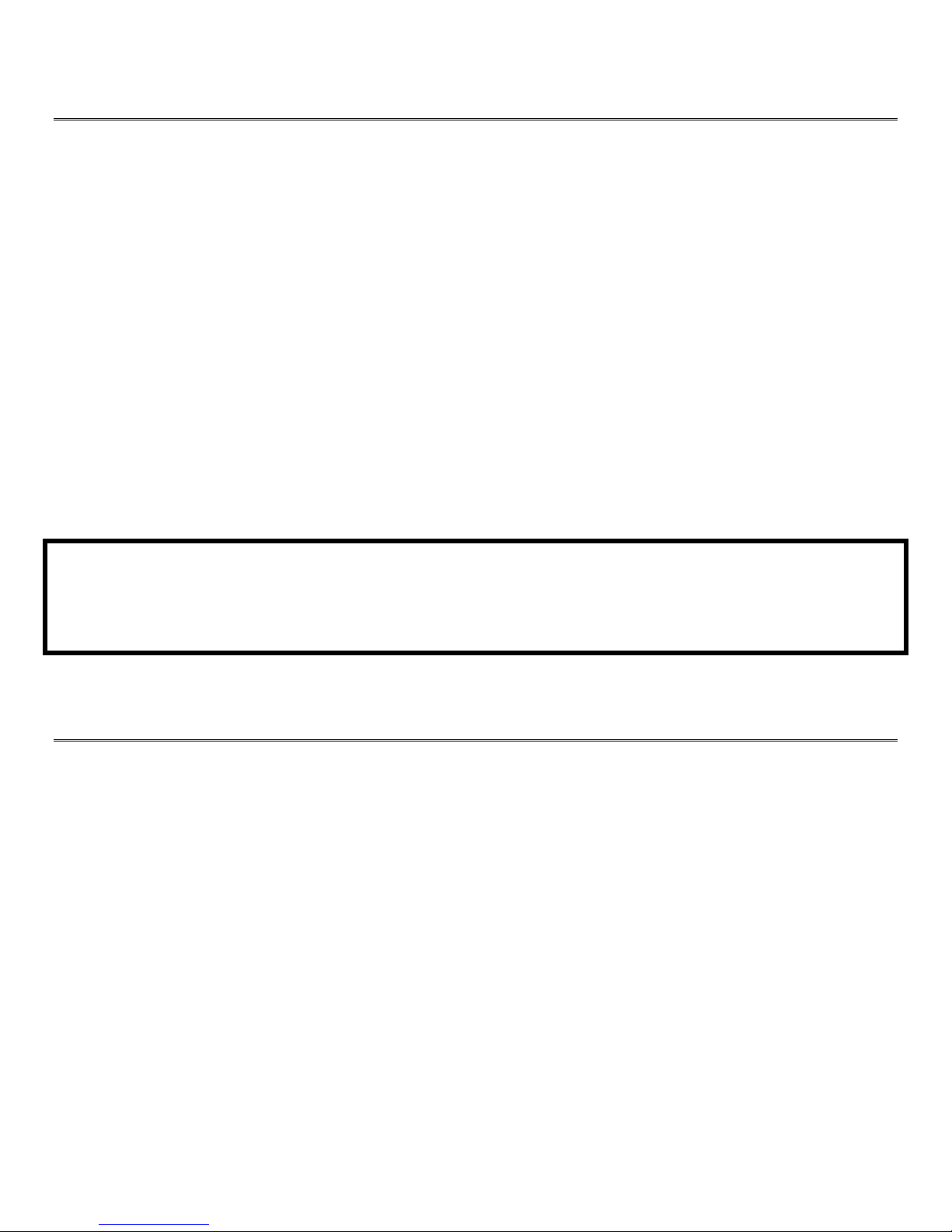

General Settings for Trace Inverter/Charger

12 Volt 24 Volt 48 Volt

Bulk 14.8 29.6 59.2

Equalize 15 – 15.5 30 – 31 60 – 62

Float 13.5 27 54

These voltage settings are ball park settings that will work for most systems. If you find your specific

gravity is not reaching 1.275-1.285 raise these settings by .1 volt increments until the specific gravity

readings indicate a fully charged battery. If the battery uses an excessive amount of water or is

overheating, lower the settings by .1 volt increments until the overcharge is removed.