Powr-Flite PF1200RT Installation and operation manual

OPERATOR’S MANUAL & PARTS LIST

WARNING: OPERATOR MUST READ AND UNDERSTAND THIS MANUAL

COMPLETELY BEFORE OPERATING THIS EQUIPMENT.

©Tacony, Inc., All rights reserved

Save These Instructions

1200 P.S.I. Multi-Surface Cleaner

PF1200RT

PF1200RT-MAN 12/2015

2

NOTES

Model Number: __________________________________________________________________

Serial Number:___________________________________________________________________

Date of Purchase: ________________________________________________________________

Retain this manual as a permanent record of your purchase.

3

IntroductIon

Check the carton for shipping damage. Carefully unpack and

inspect your new Powr-Flite equipment for shipping damage.

Each unit is tested and thoroughly inspected prior to shipping.

If damage is discovered, immediately notify the transportation

company that delivered your machine and request an

inspection. As a manufacturer, we are unable to act upon any

claim for concealed damage; you must originate the claim.

Be sure to keep the carton, packing inserts, packing lists, and

carrier’s receipt until the inspector has verified your claim.

MANUAL

This manual has important information for the use and safe operation of the multisurface cleaner.

Read this manual carefully before starting the machine. Keep the manual available at all times

and instruct all operators to read this manual.

Introduction ...................................................3

Safety Instructions ........................................4

Grounding Instructions.................................5

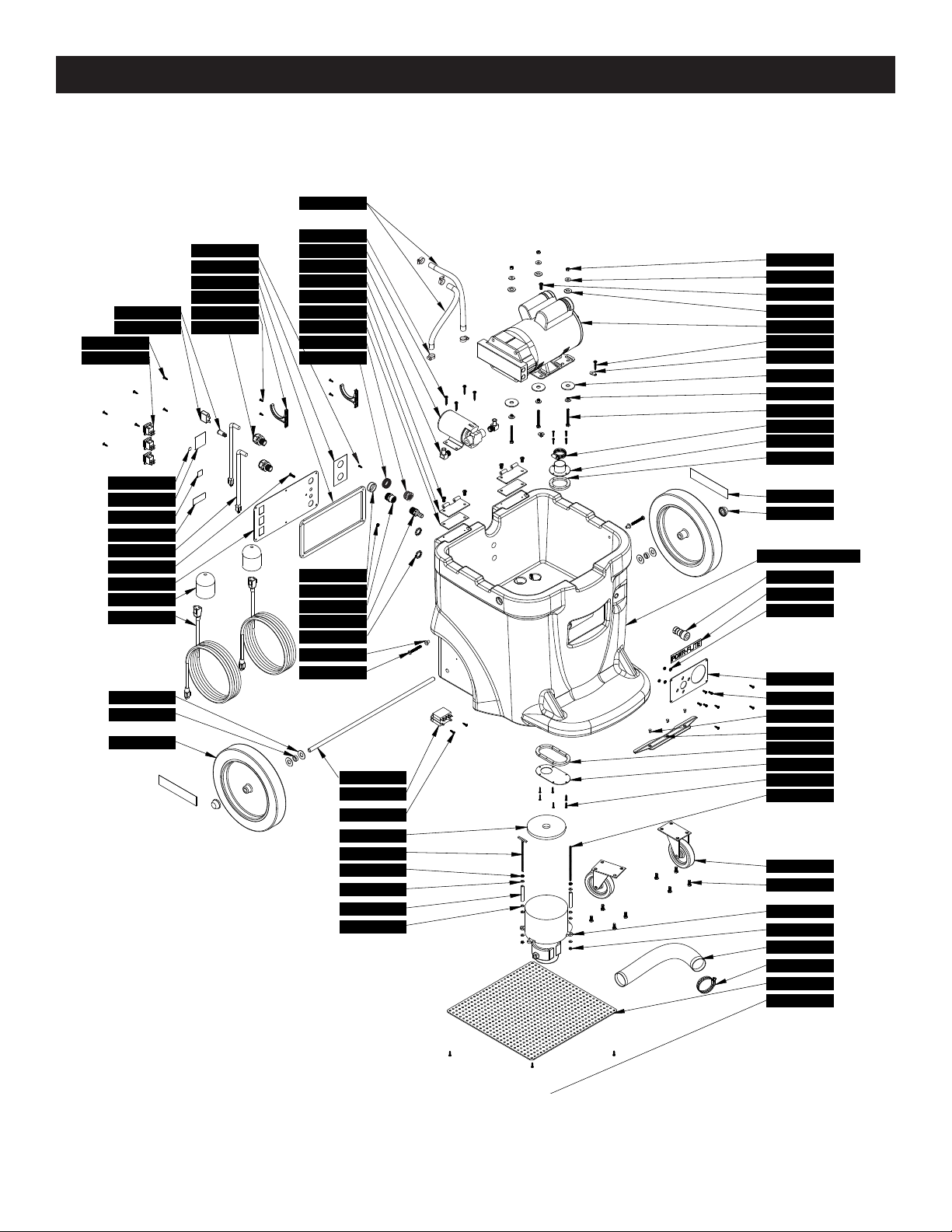

General Diagram............................................6

Operating Instructions..................................8

Maintenance Guide........................................9

Machine Specications...............................10

Troubleshooting .......................................... 11

Schematic and Parts List............................12

PROTECT THE ENVIRONMENT

Please dispose of packaging materials in an

environmentally safe way according to local

waste disposal regulations.

Always remember to recycle

Powr-Flite.com

4

WARNING!: To reduce the risk of fire, electric shock, or injury

When operating this machine, the following precautions should

always be followed:

WARNING

To avoid fire, DO NOT

use with a flammable

or combustible liquid

to clean floor.

WARNING

To avoid electric

shock, DO NOT

expose to rain.

Store Indoors.

1) DO NOT leave unit when plugged in. Unplug from outlet

when not in use and before servicing.

2) DO NOT allow unit to be used as a toy. Close attention is

necessary when used around or near children.

3) Use only as described in this manual. Use only

manufacturer’s recommended attachments.

4) DO NOT use with damaged cord or plug. If unit is

not working properly because it has been dropped,

dropped into water, left outdoors, or damaged in any

way, contact an authorized service center.

5) DO NOT handle plug or appliance with wet hands.

6) DO NOT put any objects into openings. DO NOT use

with any opening blocked: keep free of dust, lint, hair,

or anything that may reduce air flow.

7) Keep hair, loose clothing, fingers, and all parts of body

away from openings and moving parts.

8) DO NOT pick up anything that is smoking or burning

such as cigarettes, matches, or hot ashes.

9) DO NOT use to pick up hazardous chemicals.

10) Turn off all controls before unplugging.

11) Turn unit off immediately if foam or liquid comes from

machine exhaust. Empty & clean out recovery (dirty)

tank and use defoamer to correct the problem.

12) DO NOT use to pick up flammable or combustible

liquids such as gasoline or use in areas where they may

be present.

13) DO NOT use where oxygen or anesthetics are used.

14) Replace damaged or worn parts immediately with

genuine original equipment parts to maintain safety.

15) This unit must be connected to a properly grounded

outlet only. See grounding instruction on page 5.

IMPORTANT SAFETY PRECAUTIONS

5

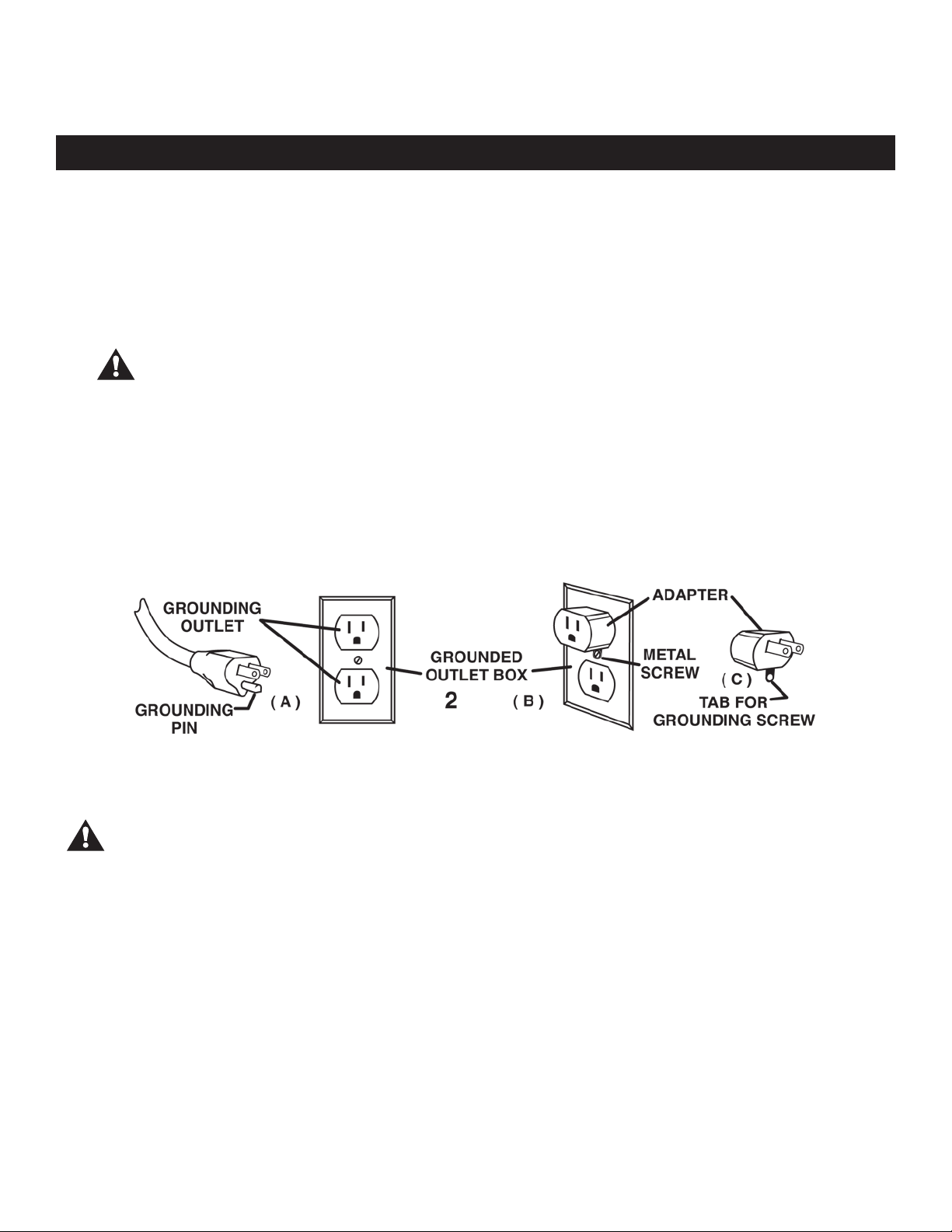

This equipment must be grounded! Grounding is a safety measure to reduce the risk of electrical shock to the

operator should the machine malfunction or stop working. Grounding provides the path of least resistance for electric

current and will trip the circuit breaker, stopping the flow of electricity.

This unit is equipped with a cord that has an equipment-grounding conductor and grounding plug. The plug must be

inserted in an appropriate outlet that is properly installed and grounded in accordance with all local codes and

ordinances. Cutting off the ground wire or using a cord that is not equipped with a ground plug will void the warranty

on the unit. Powr-Flite will accept NO liability associated with the unit.

The equipment is for use on a nominal 120-volt circuit, and have a grounded plug that looks like the plug illustrated

in Figure A. A temporary adapter that looks like the adapter illustrated in Figure B and C may be used to connect this

plug to a 2-pole receptacle as shown in Figure B if a properly grounded outlet is not available. The temporary adapter

should be used only until a properly grounded outlet (Figure A) can be installed by a qualified electrician. The green

colored rigid ear, lug, or the like, extending for the adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is used, it must be held in place by a metal screw.

Note: In Canada, the use of a temporary adapter is not permitted by the Canadian Electrical Code.

The replacement or repair of damaged wiring should only be performed by a qualified

electrician or service engineer from the manufacturer or authorized service center.

GroundInG InstructIons

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service person if you are in doubt

as to whether the outlet is properly grounded. Do not modify the plug provided with

the appliance. If it will not fit the outlet, have a proper outlet installed by a qualified

electrician.

WARNING!

WARNING!

CONNECT TO A PROPERLY GROUNDED OUTLET ONLY!

See Grounding Instructions

6

Vacuum Inlet

Recovery Tank

Hard Surface Tool

Wand Holder Clip

Solution Line

Wand Holder

Solution and

Vacuum Hose

P.S.I. Gauge

Pressure Control

GENERAL DIAGRAM

7

Loading Wheels

Autodump Outlet

Autodump Circuit

Breaker

Autodump Switch

Pump Switch

Vacuum Switch

Transport

Wheels

Cord Hook

Manual Dump

Hose

Dual Circuit

Indicator

Solution Line Inlet

GENERAL DIAGRAM

8

CLEANING WITH THE HARD SURFACE TOOL

OPTIONAL: CLEANING CARPET WITH A CARPET WAND (Not Included)

OPTIONAL: USING A PRESSURE WASHER ATTACHMENT (Not Included)

PREPARING THE CLEANING AREA

MACHINE SET UP

This machine is designed as a direct feed solution system with a recovery tank with the option to auto dump.

To set up your machine:

GENERAL INSTRUCTIONS

1. Make sure hoses are in good condition and spray nozzle on wand is tight.

2. To prep your direct feed solution system, connect the machine to the water source with a garden hose.

3. When not using the auto-dump feature, make sure the brass cap is screwed tightly on the hose connector tting

on the dump pump on the rear of the machine. If using the auto-dump feature, connect the dump hose to the

brass hose tting on the back of the dump pump and place the open end of the hose in a drain. Make sure the

drain hose (recovery tank) is closed, and the lid is tight on the recovery tank.

4. Connect the vacuum hose to the wand.

5. Plug each extension cord into a separate and grounded 15 amp wall socket circuit. The green separate circuit

light will be lit. If the light does not come on, check the circuit breaker box on the wall, and/or try different outlets

until it does turn on.

6. Prime the pump: Ensure that the pump, vacuum and auto dump switches are off. Prime the pump by squeezing

the trigger on the wand to release the water. When a steady ow of water goes through, then your machine is

ready to be used.

7. Turn the vacuum and pump switch to on. If using the auto dump feature, turn on the autodump switch.

8. To adjust the pressure, while the trigger is activated on the hard surface tool with the pump switch on, adjust the

pressure unloader next to the PSI gage between 400-1200 PSI.

1. It is suggested to sweep the area to be cleaned prior to operating the machine.

2. Pre-Spray – with the use of a pump-up sprayer, pre-spray the oor with an approved hard surface pre-spray deter-

gent. Only use commercially available oor cleaners intended for machine application. Follow proper mixing and

handling instructions on the detergent bottle.

1. Verify the vacuum hose and solution hose are securely connected to the machine and hard surface tool.

2. Ensure the relief valve on the hard surface tool is closed. If the hard surface tool starts to stick to the oor due to

excessive vacuum pressure, slide the suction relief valve to adjust the pressure located at the head of the unit.

3. Turn on the pump and vacuum switches. Turn on the Auto-Sump switch if using this feature.

4. For optimum cleaning results pull trigger while moving the hard surface tool in a front to back motion.

Note: Use defoamer with each use to prevent vacuum ooding.

5. When nished with the job, shut off all switches. Before disconnecting solution hose, relieve the water pressure from

the hard surface tool by holding the trigger on the hard surface tool.

1. Verify the vacuum hose and solution hose are securely connected to the machine and carpet wand.

2. Set the PSI to no more than 800 psi to clean carpet. CAUTION: Damage to carpet may occure if the PSI is set

too high.

3. When nished with the job, shut off all switches. Before disconnecting solution hose, relieve the water pressure from

the carpet wand by holding the trigger on the carpet wand.

1. Verify the vacuum hose and solution hose are securely connected to the machine and pressure washer spray wand.

2. Set the PSI to the desired pressure between 400-1200 PSI.

3. When nished with the job, shut off all switches. Before disconnecting solution hose, relieve the water pressure from

the pressure washer spray wand by holding the trigger on the pressure washer spray wand

WARNING!

TO AVOID SERIOUS INJURY, NEVER POINT SPRAY NOZZLE

AT YOURSELF, OTHER PERSONS OR ANIMALS!

9

OPTIONAL: DRYING YOUR FLOOR WITH SQUEEGEE TOOL (Not Included)

DRAINING RECOVERY TANK

MAINTENANCE

STORING

GENERAL INSTRUCTIONS

1. Verify the vacuum hose is securely connected to the machine and wand. Connect the squeegee tool to the wand.

2. Turn on the vacuum switch to vacuum excess water.

1. Turn off all switches.

2. Drain the recovery tank by holding the end of the drain hose with the cap above the machine. Remove the cap on

the drain hose. Lower the drain hose over a drain or a bucket to drain the recovery tank.

Note: When using the Auto Dump feature, the recovery tank must be rinsed and then drained with the drain hose after

each use.

To keep the machine in good working condition, maintenance procedures should be followed after each use.

CAUTION: When servicing machine turn the power off and unplug the machine from the wall outlet.

1.Drain and flush the recovery tank, intake hoses, and any wand or hand tool used with clean water. Make sure the

discharge connector is closed.

2.Thoroughly clean the inlet basket filter.

3.Inspect power cords for damage. Replace damaged cords and plugs

immediately. Do not use the machine with a damaged cord or plug.

4.Inspect vacuum hoses for holes and loose cuffs.

5.Clean machine housing with an all purpose cleaner and damp cloth.

6.Inspect the machine for leaks and loose hardware.

7.Lubricate wheels and casters with oil or grease .

8. Check and clean inlet filter

1.Machine should be completely empty and dry before storing.

2.Store machine in a dry area in the upright position.

3.Open recovery tank cover to promote air circulation.

CAUTION: Do not expose to rain or freezing temperatures, store indoors.

10

PRODUCT SPECIFICATIONS

MODEL

PFX1200RT

Power Cord 25 ft. 12 gauge, 3-wire (2)

Water Supply Hose 25 ft (2)

Recovery Tank Capacity 15 gallons

Vacumm Intake Hose 30 ft

Water Lift 135 in

CFM 92

Front Wheel Size 4 in

Rear Wheel Size 12 in

Tank Construction Polyethylene

Overcharge Protection Electronic oat / auto ON-OFF

Discharge Pump Self-priming impeller pump

Discharge Rate 5 GPM

Filter System Stainless Steel Filter

Weight 158 lbs

Dimensions 41"H x 29" L x 22" W

Warranty 10 years housing, 1 year motor

MODEL

HYDRO WAND HP-12

Head Diameter 15"

Spray jets 2 x 90 degree

Rated PSI 2600

Max Flow Rate 2.2 GPM

11

PROBLEM CAUSE SOLUTION

Poor pick up. Inlet basket filter is clogged. Clean filter.

Loose drain hose connection. Tighten drain hose.

Loose recovery tank lid. Position the lid correctly.

Damaged hose. Replace hose.

Suction relief is open on wand. Adjust or close suction relief on wand.

Vacuum motor does not operate Unplugged cord. Check connection to pigtail and wall

Faulty switch or loose wiring. Contact Service Center.

Tripped building circuit breaker. Reset breaker.

Defective vacuum motor. Contact Service Center.

Recovery tank is full. Empty the recovery tank.

Discharge pump does not operate Unplugged cord. Check connection to pigtail and wall

Faulty switch or loose wiring. Contact Service Center.

Tripped building circuit breaker. Reset breaker.

Defective vacuum motor. Contact Service Center.

Recovery tank is not full enough. Discharge pump will turn on when

there’s enough water in the recovery

tank.

Amount of discharge water dwindles. Worn impeller. Contact Service Center.

1200 PSI pump does not operate or has

low pressure.

Unplugged cord. Check connection to pigtail and wall.

Faulty switch or loose wiring. Contact Service Center.

Tripped building circuit breaker. Reset breaker.

Defective PSI pump. Contact Service Center.

Tripped pump circuit breaker. Reset breaker on PSI pump.

TROUBLESHOOTING

12

MODEL PFX1200RT PARTS

7DL008 X4

70079C

7CZ001

17850

18666

32966

71379A

71507A

71639A

71644A

72000A

72365B

72387A

72388A

72620ABREPRO

72625A

72630A

72632C

72633A

72635A

72636A

72641A

72642A

72661B

72662A

72665A

72684A

72820A

7BF003

7BF008

7BF030

7BS003

7CM007

7CW002

7DL005

7DT001

7EW001

7GL002

FP8

M1374 PC25

PD8

PX112

PX154

X1442

PX215

PX6

PX65

PX86

X1003

X1278

X1316

X1334

X1335

X1336

X1341 X4

X1367

X1368

X8261

X8008N

X8212

X8213

X8235

X8256

X8278

X8272

X8459

X8851

X8976

X9014

X9045A

X9066

X9069

X9079

X9098

X9168

X9204

X9214

X9253

X9324

X9687

X9718

72387A

PFX1200RT base assembly

13

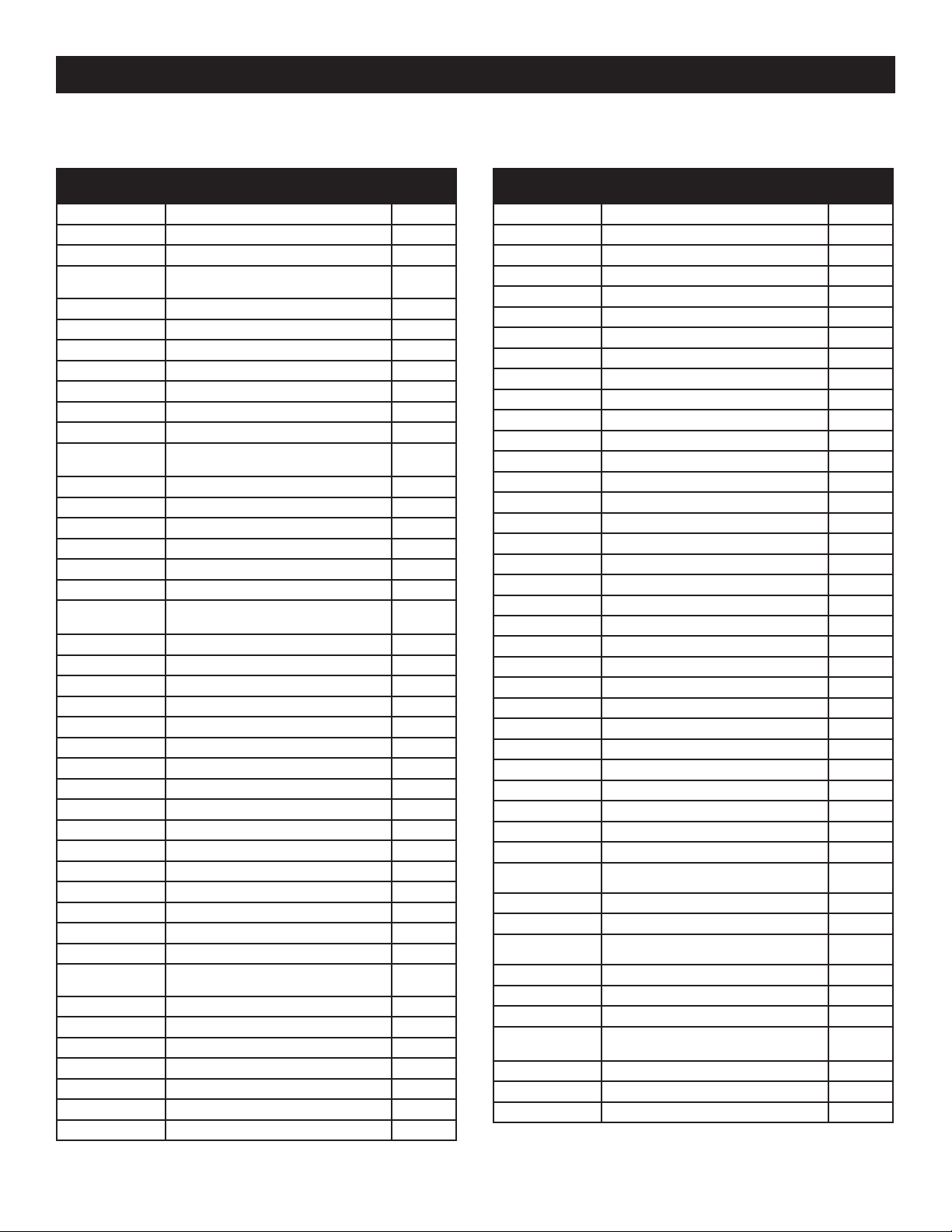

MODEL PFX1200RT PARTS

PFX1200RT base assembly

PART NO. DESCRIPTION QTY

NEEDED

17850 WASHER PLAIN 6

18666 WASHER PLAIN .5” ID 3

32966 SWITCH ROCKER 3

70079C BULK HOSE 1/2” WIRE

REINFORCED 38″

71379A RELAY 25A 120V 1

71449A BAG, CORD WRAP FOR SHIPMENT 2

71507A ELBOW 1/2 H - 3/8 MPT 2

71639A 1/4-20 X 1-1/2 BOLT 3

71644A SCREW #10 X1 PHIL PAN SS 1

72000A 10/24 5-1/2 THREADED ROD SS 1

72365A VAC 3 STAGE 120V 1

72387A SCREW #8 X 5/8 BLACK PHIL PAN

TAPPING 12

72388A SCREW #10 X 5/8 4

72620ABREPRO BASE BLACK 1

72625A COVER VACUUM MANIFOLD 1

72630A COVER VACUUM MANIFOLD FLAT 1

72632C SWITCH PANEL RIPTIDE 1

72633A AXLE 1/2” DIA 1

72635A SPACER 1/2” ID X 3/4” OD X 1/4”

LONG 2

72636A COVER BASE BOTTOM 1

72641A GASKET VAC MANIFOLD SHORT 1

72642A GASKET VAC MANIFOLD 1

72661B WAND HOLDER PFX1350/PRO500 1

72662A SCREW #10 X 1/2” PHIL BLACK 3

72665A INSERT TEE NUT 1/4-20 THREAD 2

72684A SCREW 1/4 - 20 X 2 - 1/2 2

72820A 1/8” SPACER 2

7BF003 NUT KEPS #10-24 2

7BF008 NUT 10-32 KEPS SS 1

7BF030 NUT 10-24 NYLOC INSERT SS 2

7BS003 SCREW 1/4-20 X 1/2 PHIL PAN SS 4

7CM007 WASHER 1/2 FLAT SS 4

7CW002 SCREW #6 X 3/4 PHIL PAN SS 10

7CZ001 HOSE, VACUUM 2” DIAMETER BULK 20″

7DL005 CLAMP 1-1/2 1

7DL008 CLAMP 1-1/2 WORM GEAR

STAINLESS HEX 1

7DT001 BOLT 4/16 - 18 X 5/8 8

7EW001 1/4-20x 3/4 PHIL PAN 1

7GL002 NUT PUSH 1/2” 2

FP8 CAP WITH CHAIN 1

M1374 12/3 SJTW 25’ EXT CORD 2

PC25 BARB 1/2” X 1/2” MALE/MALE 1

PD8 STRAIN RELIEF 1/2 NPT 2

PART NO. DESCRIPTION QTY

NEEDED

PX112 CORD PIGTAIL 12/3 SJT 2

PX154 GARDEN HOSE FITTING 1

PX215 CLAMP 2 21/2” WORM GEAR 1

PX6 COUPLER FEMALE 1/4” 1

PX65 CASTER 4” BLACK 2

PX86 GREEN LIGHT INDICATOR 1

X1003 MADE IN THE USA LABEL 1

X1278 PUMPTEC PUMP WITH PLUMB 1

X1316 GASKET CONTROL PANEL 1

X1334 PRESSURE REGULATOR PLATE 1

X1335 HOSE THREAD 3/4” PIPE THREAD 1

X1336 RIPTIDE LABEL 2

X1341 KNOCK NUT 1/4-20 4

X1367 BOOT COVER FOR PLUG 2

X1368 LABEL HOSE INLET OUTLET 1

X1369 RIPTIDE WIRING HARNESS 1

X1442 FILTER, GARDEN HOSE INLET 1

X8008N NUT LOCK 1/2” STEEL 2

X8212 WASHER-LOCK (1/4”) 3

X8213 NUT 1/4-20 HEX FINISH ZINC 3

X8235 WASHER 1/4 FLAT 3

X8256 NUT 8-32 KEPS ZINC 4

X8261 KICKSTAND SCREW 5

X8272 SCREW 8-32 X 1/2 TRUSS 4

X8449 POWR-FLITE WARRANTY CARD 1

X8451 LABEL, PLAIN BOX 4 X 6 1

X8459 LABEL, SERIAL NUMBER, PLAIN 1

X8460 QUALITY CONTROL TICKET GREEN 1

X8851 SCREW, 10-32 x 1 MACHINE PH 1

X8976 LABEL, WARNING 1

X9014 TANK HINGE 2

X9045A SPACER VAC MOTOR 3 STAGE 2

X9066 WHEEL 12 X 1-3/4 NON MARKING

GRAY TIRE 2

X9069 END LOOP SS WITH TWO HOLES 1

X9079 GASKET 3/8” DONUT MOTOR SEAL 1

X9098 SCREW A PONIT #10 X 1 BLACK

ZINC 4

X9168 SPACER PAN HINGE 2

X9204 ROD 10-24 T BOLT SS 1

X9214 LABEL, GROUND SYMBOL 1

X9253 PUMP 1/10HP 360GPH SELF

PRIMING 1

X9324 5 AMP CIRCUIT BREAKER 1

X9687 POWR-FLITE LABEL 1

X9718 CORD HOOK 2

14

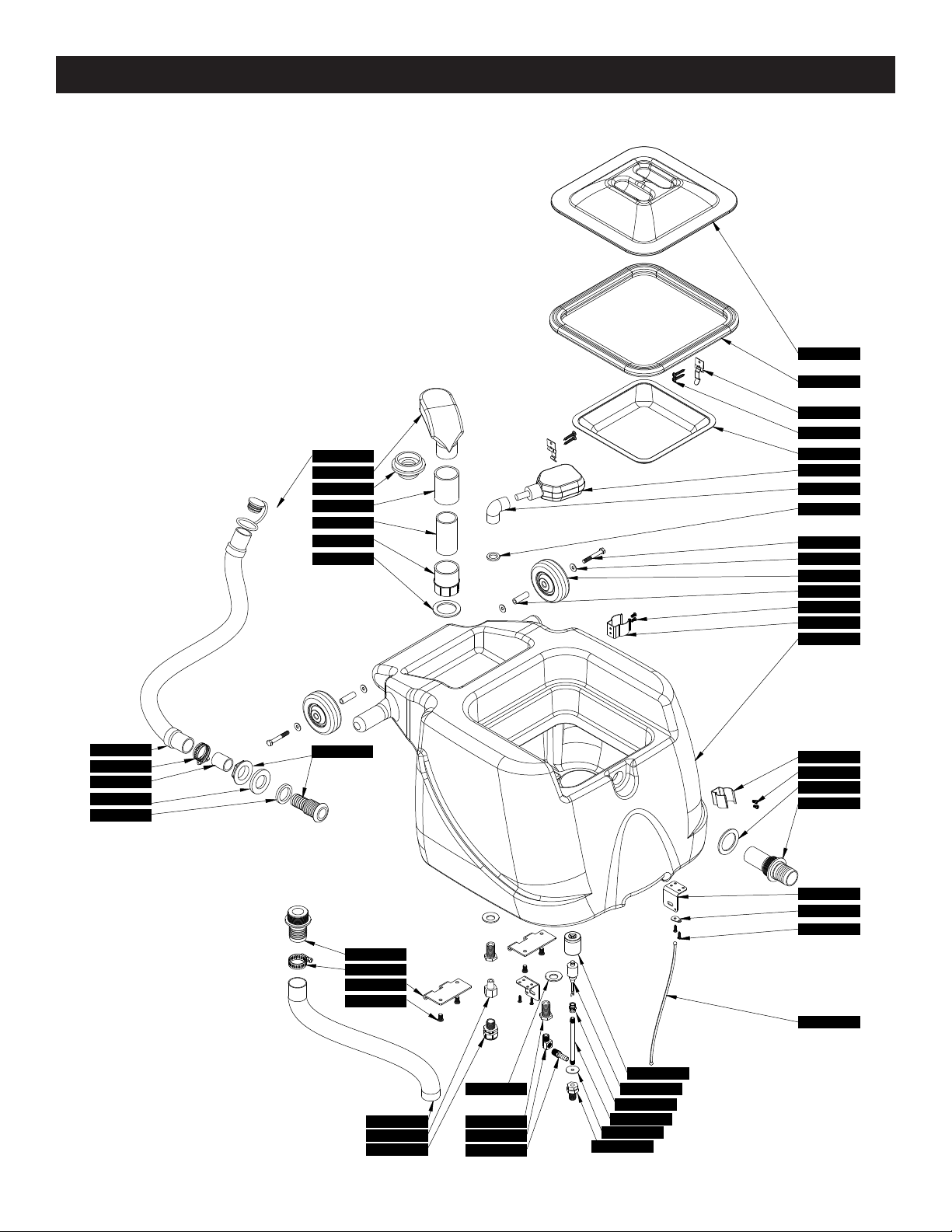

MODEL PFX1200RT PARTS

72656A

72660A

X9224 PC49

PX85

72645A

72173A

X9239

72326A

X9236

PX48

PX25

X9213

X9221

7DL005

PAS37

72666A

72631A

PAS36

7BH004

72388A

71644A

7BS003

72486A

PD8

X9014

72619BU

PX63

72615A

72677A

72680A

72679A

72323B

72321A

X9154

72678A

PX33

PX14 X8235

72274A

72115A

X8025

7AJ004

X9069

PX48G

70343A

7DA001

71328A

PX14A

7DL005

72173B

7BH004

72799B

PFX1200RT recovery tank assembly

15

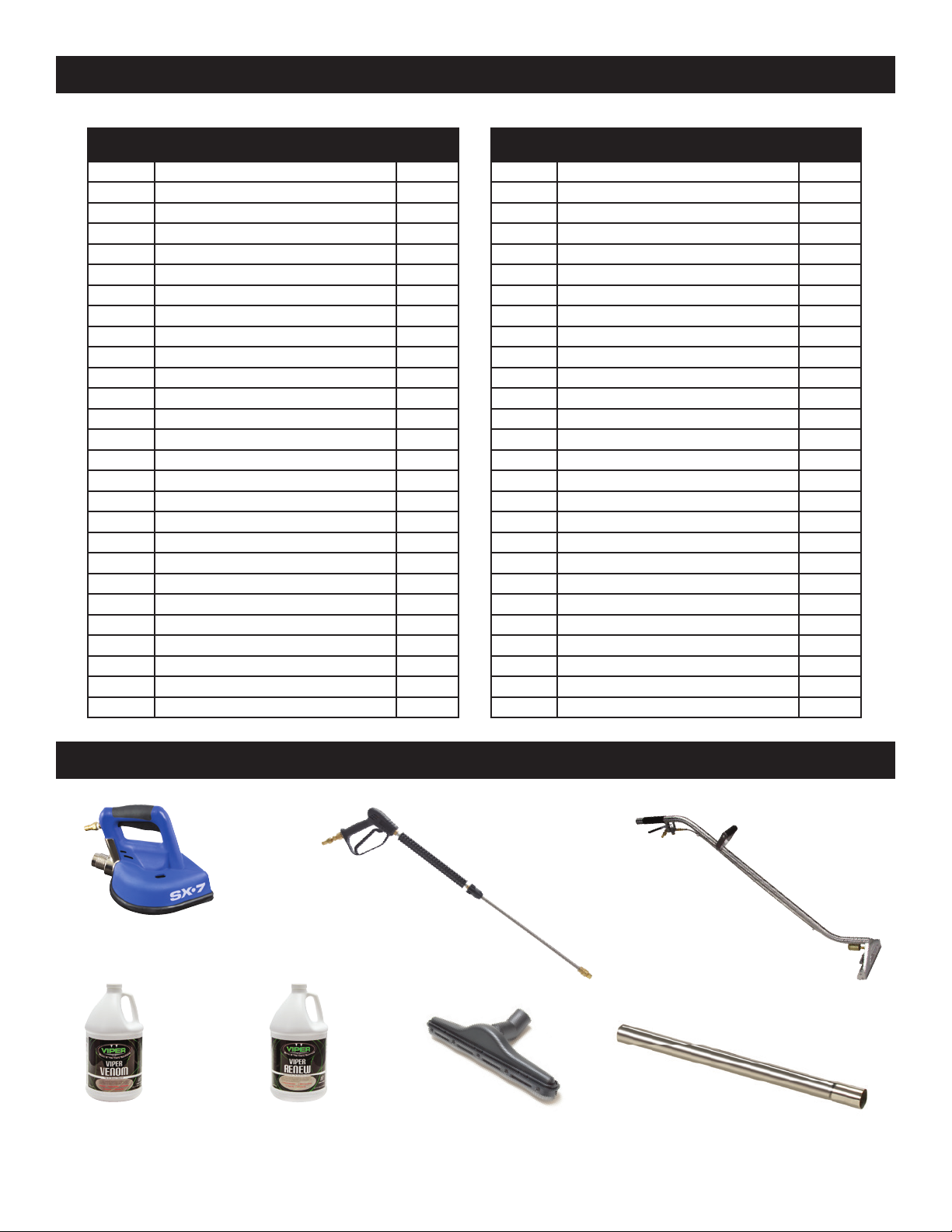

MODEL PFX1200RT PARTS

OPTIONAL ACCESSORIES NOT INCLUDED

PFX1200RT recovery tank assembly

PART NO. DESCRIPTION QTY

NEEDED

70343A SWITCH FLOAT 2 POLE 1

71328A SHIELD FLOAT SWITCH 1

71644A SCREW #10 X1 PHIL PAN SS 4

72115A WASHER 5/8 X 1-3/16 BONDED SEAL 1

72173A CLIP SPRING 1

72173B PIVOTING TOOL HOLDER 1

72274A WASHER 3/4” NEOPRENE BOND 2

72321A LID TANK 1

72323B GASKET LID 1

72326A FILTER INLET 1

72388A SCREW #10 X 5/8 4

72486A SPACER 1.625 LONG .5 OD 2

72615A COUPLING PVC 1-1/2 1

72619BU TANK RECYCLING BLUE 1

72631A LATCH BRACKET 2

72645A BOLT 5/16-18 X 2-1/4 2

72656A BLACK 1-1/2 WIRE-REINFORCED HOSE 32″

72660A ROPE SOLID BRAID 27″

72663A BOX, 41 X 24.5 X 37.5 1

72664A INSERT, BOX, 24.25 X 71 1

72666A INLET FITTING SHORT 1

72677A DRAIN FITTING 1” 1

72678A TUBING VINYL 1” ID 1

72679A GASKET INNER DRAIN 1

72680A GASKET DRAIN OUTER 1

72799B 5” LONG 1/8” THREADED PIPE 1

7AJ004 ANCHOR CONNECTOR 1/8 NPT 1

PART NO. DESCRIPTION QTY

NEEDED

7BH004 SCREW 10-32 X 3/8 PHIL PAN SS 4

7BS003 SCREW 1/4-20 X 1/2 PHIL PAN SS 4

7DA001 COUPLING 1/8-1/8 PIPE 1

7DL005 CLAMP 1-1/2 1

PAS36 PLUG DRAIN HOSE 1

PAS37 HOSE DRAIN 1

PC49 1/4” 90 DEGREE STREET ELBOW 1

PD8 STRAIN RELIEF 1/2 NPT 1

PX14 VALVE GASKET 1

PX14A VALVE GASKET 1

PX25 FITTING PLASTIC BULKHEAD 1

PX33 VACUUM TUBE 1

PX48 FITTING BRASS BULKHEAD 3/4” 2

PX48G GASKET FIBER 1

PX63 COUPLER PLASTIC 1-1/2” 1

PX85 BARB 1/4” X 3/8” MALE/MALE 1

X8025 WHEEL BLACK 4” X 1-1/4” 2

X8235 WASHER 1/4 FLAT 4

X9014 TANK HINGE 2

X9069 END LOOP SS WITH TWO HOLES 1

X9154 PIPE PVC 1

X9213 FLOAT SWITCH 1

X9221 HOLD DOWN LATCH FOR INLET FILTER 2

X9224 ADAPTOR 1/2 TO 1/4 NPT 1

X9236 FILTER VAC INLET PROTECTION 1

X9239 ELBOW PVC 1/2 NPT 1

X9874 SCOTCHWELD STRUCTURAL ADHESIVE 0.025

7" Spinner Hand Tool

Item# HP7

Wet/Dry Vac Wand

Item# WD29

(2 required)

Viper Renew

for restorative cleaning

Item# VR4

Viper Venom

for routine cleaning

Item# VV4

Wet/Dry Vac Tool

Item# WD30A

Pressure Washer Gun

Item# X1470

WonderWand™

1000 p.s.i., 3 jet

Item# WW1000

A Tacony Company

3101 Wichita Court • Ft. Worth, TX 76140-1755

1-800-880-2913 • Fax: 1-817-551-0719 • www.Powr-Flite.com

PFX1200RT-MAN 12/2015

Other manuals for PF1200RT

1

Table of contents

Other Powr-Flite Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Kärcher

Kärcher HD 5/14 C Original instructions

Kärcher

Kärcher HDS 8/18-4 C manual

Clarke

Clarke PLV145H Operating & maintenance instructions

AR Blue Clean

AR Blue Clean AR112S Assembly, care and use instructions

Clarke

Clarke Power Wash KING 135 operating & maintenance manual

Nilfisk-ALTO

Nilfisk-ALTO Uno Booster operating instructions