Powr-Flite PF1200RT User manual

OPERATOR’S MANUAL

WARNING: OPERATOR MUST READ AND UNDERSTAND THIS MANUAL

COMPLETELY BEFORE OPERATING THIS EQUIPMENT.

©Tacony Corporation, All rights reserved

Save These Instructions

PF1200RT-MAN 05/2021

Riptide

Multi-Surface Cleaner

PF1200RT

2

Model Number:

Serial Number:

Date of Purchase:

Retain this manual as a permanent record of your purchase.

NOTES

3

INTRODUCTION

Congratulations on your purchase of a Powr-Flite a 1200 P.S.I. Multi-Surface Cleaner,

PF1200RT. You are now equipped to handle any and all commercial carpet cleaning jobs.

Shipping and Damage

This equipment is thoroughly inspected, tested, and packaged to provide equipment in

good operating condition. It is beyond our control after the equipment is turned over to a

freight carrier. The freight carrier received and signed for the equipment in good condition.

Consequently, it is most important to protect your interest by carefully complying with the

following instructions:

Please inspect your cartons for any damage (including concealed damage) that might have

occurred during shipment. Any damage is the responsibility of the freight carrier and should be

reported to the freight carrier immediately. It is your responsibility to issue a claim and to receive

compensation from the freight carrier for any damage done in transit. Damage of this sort is not

warranted.

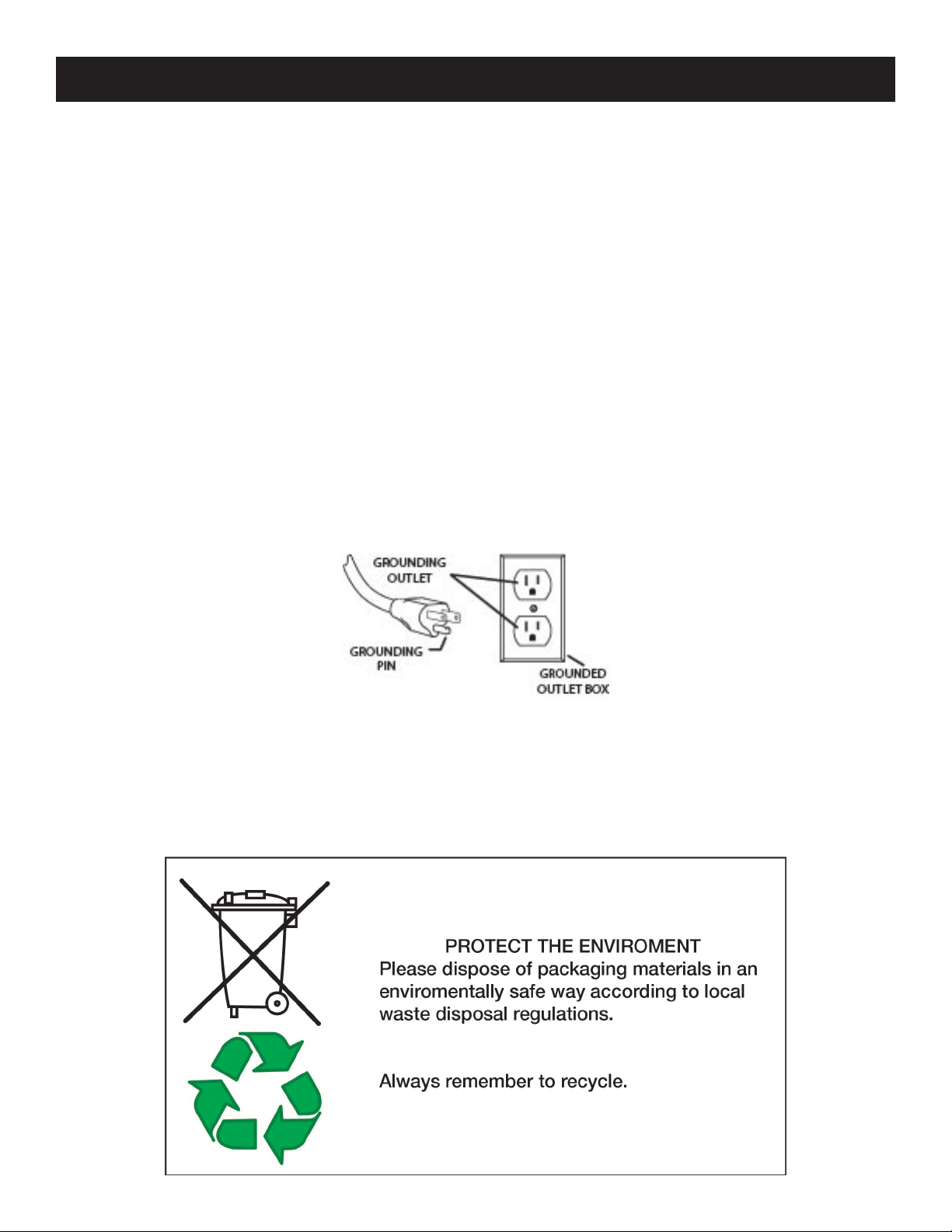

This extractor must be properly grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electrical current to reduce the risk of electric shock.

This machine is equipped with a pigtail cord having an equipment-grounding conductor and

grounding plug. The pigtail must be inserted into an appropriate 12 gauge 3 prong extension

cord. This unit is for use on a nominal 115 volt circuit and has a grounded plug that looks like the

plug illustrated in (Fig. A).

A

4

IMPORTANT SAFETY PRECAUTIONS

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE USING THIS UNIT

Read and understand this owner’s manual and all labels on the unit before operating. Safety is a

combination of common sense,staying alert, and knowing how your unit works. Use this unit only

as described in this manual. Use only manufacturer’s recommended attachments. To reduce the

risk of personal injury or damage to your unit use only recommended accessories.

WARNING To avoid fire, DO NOT use with a flammable or combustible liquid or floor cleaner.

WARNING To avoid electric shock, DO NOT expose to rain. Store Indoors.

When using this Midsize extractor, basic precautions should always be followed, including the

following:

1) DO NOT leave unit when plugged in. Unplug from outlet when not in use and before servicing.

2) DO NOT allow unit to be used as a toy. Close attention is necessary when used around or near

children.

3) Use only as described in this manual. Use only manufacturer’s recommended attachments.

4) DO NOT use with damaged cord or plug. If unit is not working properly because it has been

dropped, dropped into water, left outdoors, or damaged in any way, contact a service center

5) DO NOT handle plug or appliance with wet hands.

6) DO NOT put any objects into openings.

DO NOT use with any opening blocked: keep free of dust, lint, hair, or anything that may

reduce air flow.

7) Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

8) DO NOT pick up anything that is smoking or burning such as cigarettes, matches, or hot ashes.

9) DO NOT use to pick up hazardous chemicals.

10) Turn off all controls before unplugging.

11) Turn unit off immediately if foam or liquid comes from machine exhaust. Empty & clean out

recovery (dirty) tank and use defoamer to correct the problem.

12) DO NOT use to pick up flammable or combustible liquids such as gasoline or use in areas

where they may be present.

13) DO NOT use where oxygen or anesthetics are used.

14) Replace damaged or worn parts immediately with genuine original equipment parts to

maintain safety.

15) This unit must be connected to a properly grounded outlet only. See grounding instructions.

WARNING!

TO AVOID SERIOUS INJURY, NEVER POINT SPRAY NOZZLE

AT YOURSELF, OTHER PERSONS OR ANIMALS!

5

GENERAL DIAGRAM

Hard Surface Tool

Solution Line

Pressure Adjustment

Wand Holder Clip

Pressure Gauge

Solution and Vacuum Hose

Wand Holder

Recovery Tank

Vacuum Inlet

6

GENERAL DIAGRAM

Cord Hook

Dual Circuit

Indicator

Autodump Circuit

Breaker

Transport

Wheels

Autodump Switch

Pump Switch

Vacuum Switch

Autodump Outlet

Solution Line Inlet

Loading WheelsManual Dump Hose

7

GENERAL INSTRUCTIONS

MACHINE SET UP

This machine is designed as a direct feed solution system with a recovery tank with the option

to auto dump.

To set up your machine:

GENERAL INSTRUCTIONS

1. Make sure hoses are in good condition and spray nozzle on wand is tight.

2. To prep your direct feed solution system, connect the machine to the water source with a

garden hose.

3. When not using the auto dump feature, make sure the brass cap is screwed tightly on the

hose connector fitting on the dump pump on the rear of the machine. If using the auto dump

feature, connect the dump hose to the brass hose fitting on the back of the dump pump and

place the open end of the hose in a drain. Make sure the drain hose (recovery tank) is closed,

and the lid is tight on the recovery tank.

4. Connect the vacuum hose to the wand.

5. Plug each extension cord into a separate and grounded 15 amp wall socket circuit. The green

dual circuit light will be lit. If the light does not come on, check the circuit breaker box on the

wall, and/or try different outlets until it does turn on.

6. Prime the pump: Ensure that the pump, vacuum and auto dump switches are off. Prime the

pump by squeezing the trigger on the wand to release the water. When a steady flow of water

goes through, then your machine is ready to be used.

7. Turn on the vacuum and pump switch. If using the auto dump feature, turn on the auto dump

switch.

8. To adjust the pressure, while the trigger is activated on the hard surface tool with the pump

switch on, adjust the pressure unloader, next to the PSI gage, to between 400-1200 PSI.

CLEANING WITH THE HARD SURFACE TOOL

PREPARING THE CLEANING AREA

1. It is suggested to sweep the area to be cleaned prior to operating the machine.

2. Pre-Spray – with the use of a pump-up sprayer, pre-spray the floor with an approved hard

surface pre-spray detergent.

Only use commercially available floor cleaners intended for machine application. Follow proper

mixing and handling instructions on the detergent bottle.

1. Verify the vacuum hose and solution hose are securely connected to the machine and hard

surface tool.

2. Ensure the relief valve on the hard surface tool is closed. If the hard surface tool starts to

stick to the floor due to excessive vacuum pressure, slide the suction relief valve to adjust the

pressure located at the head of the unit.

3. Turn on the pump and vacuum switches. Turn on the auto-dump switch if using this feature.

4. For optimum cleaning results pull trigger while moving the hard surface tool in a front to back

motion.

Note: Use defoamer with each use to prevent vacuum flooding.

5. When finished with the job, shut off all switches. Before disconnecting solution hose, relieve

the water pressure from the hard surface tool by holding the trigger on the hard surface tool.

8

OPTIONAL: USING A PRESSURE WASHER ATTACHMENT (Not Included)

OPTIONAL: CLEANING CARPET WITH A CARPET WAND (Not Included)

MAINTENANCE

DRAINING RECOVERY TANK

OPTIONAL: DRYING YOUR FLOOR WITH A SQUEEGEE TOOL (Not Included)

1. Verify the vacuum hose and solution hose are securely connected to the machine and carpet

wand.

2. Set the PSI to no more than 800 psi to clean carpet. CAUTION: Damage to carpet may occur

if the PSI is set too high.

3. When finished with the job, shut off all switches. Before disconnecting solution hose, relieve

the water pressure from the carpet wand by holding the trigger on the carpet wand.

1. Verify the vacuum hose and solution hose are securely connected to the machine and

pressure washer spray wand.

2. Set the PSI to the desired pressure between 400-1200 PSI.

3. When finished with the job, shut off all switches. Before disconnecting solution hose, relieve

the water pressure from the pressure washer spray wand by holding the trigger on the pressure

washer spray wand.

WARNING!

TO AVOID SERIOUS INJURY, NEVER POINT SPRAY NOZZLE

AT YOURSELF, OTHER PERSONS OR ANIMALS!

1. Verify the vacuum hose is securely connected to the machine and wand. Connect the

squeegee tool to the wand.

2. Turn on the vacuum switch to vacuum excess water.

1. Turn off all switches.

2. Drain the recovery tank by holding the end of the drain hose with the cap above the machine.

Remove the cap on the drain hose. Lower the drain hose over a drain or a bucket to drain the

recovery tank.

Note: When using the auto dump feature, the recovery tank must be rinsed and then drained

with the drain hose after each use.

To keep the machine in good working condition, maintenance procedures should be followed

after each use.

CAUTION: When servicing machine turn the power off and unplug the machine from the wall

outlet.

1. Drain and flush the recovery tank, intake hoses, and any wand or hand tool used with clean

water. Make sure the discharge connector is closed.

2. Thoroughly clean the inlet basket filter.

3. Inspect power cords for damage. Replace damaged cords and plugs immediately. Do not use

the machine with a damaged cord or plug.

GENERAL INSTRUCTIONS

9

STORING

4. Inspect vacuum hoses for holes and loose cuffs.

5. Clean machine housing with an all purpose cleaner and damp cloth.

6. Inspect the machine for leaks and loose hardware.

7. Lubricate wheels and casters with oil or grease .

8. Check and clean inlet filter.

1. Machine should be completely empty and dry before

storing.

2. Store machine in a dry area in the upright position.

3. Open recovery tank cover to promote air circulation.

CAUTION: Do not expose to rain or freezing temperatures,

store indoors.

PRODUCT SPECIFICATIONS

MODEL PFX1200RT

Power Cord 25 ft. 12 gauge, 3-wire (2)

Water Supply Hose 25 ft. (2)

Recovery Tank Capacity 15 gallons

Vacuum Intake Hose 30 ft.

Water Lift 135 in.

CFM 92

Front Wheel Size 4 in.

Rear Wheel Size 12 in.

Tank Construction Polyethylene

Overcharge Protection Electronic float / auto

ON-OFF

Discharge Pump Self-priming impeller pump

Discharge Rate 5 GPM

Filter System Stainless Steel Filter

Weight 158 lbs.

Dimensions 41”H x 29” L x 22” W

Warranty 10 years housing,

1 year motor

MODEL HYDRO WAND HP-12

Head Diameter 15”

Spray jets 2 x 90 degree

Rated PSI 2600

Max Flow Rate 2.2 GPM

10

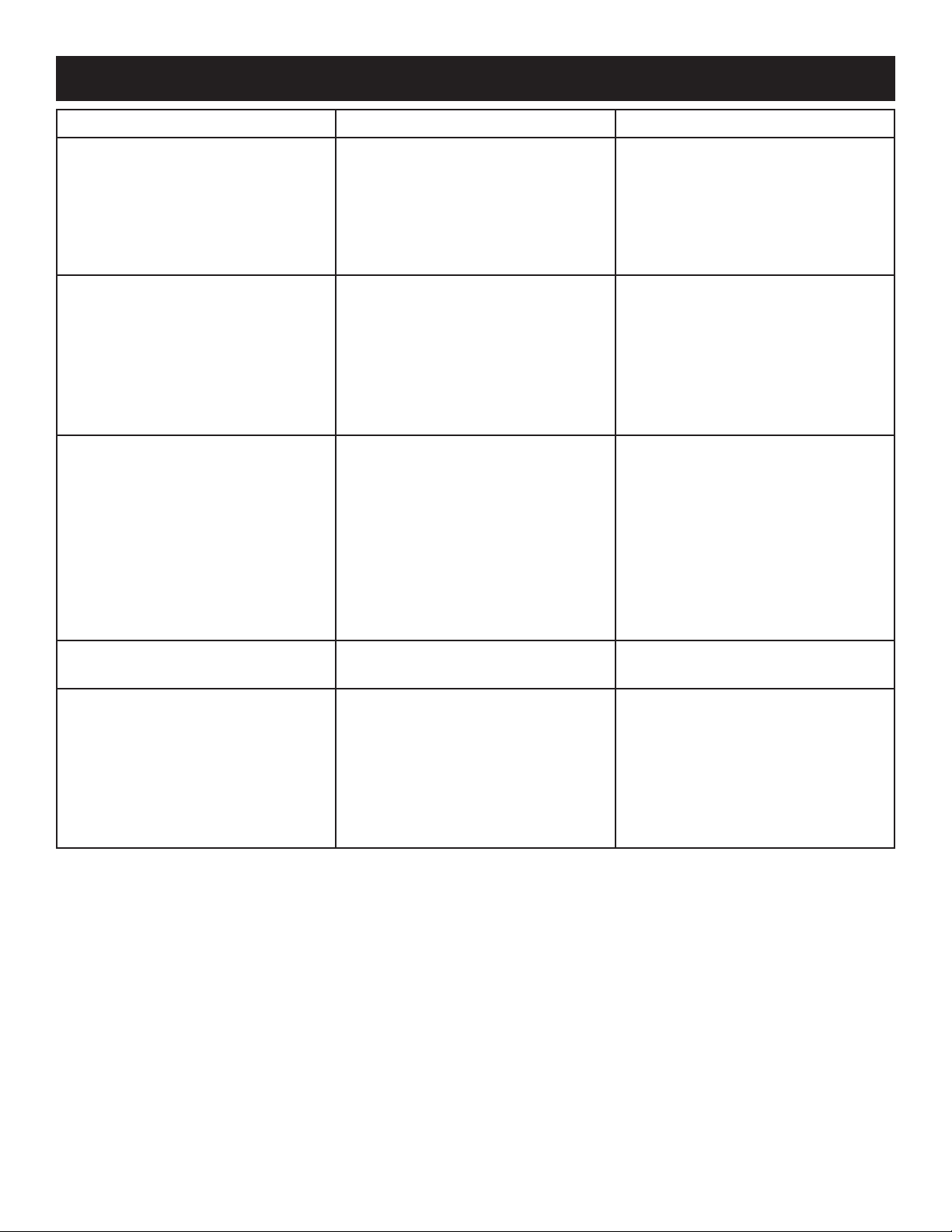

PROBLEM CAUSE SOLUTION

Poor pick up.

Inlet basket filter is clogged.

Loose drain hose connection.

Loose recovery tank lid.

Damaged hose.

Suction relief is open on

wand.

Clean filter.

Tighten drain hose.

Position the lid correctly.

Replace hose.

Adjust or close suction relief

on wand.

Vacuum motor does not

operate.

Unplugged cord.

Faulty switch or loose wiring.

Tripped building circuit

breaker.

Defective vacuum motor.

Recovery tank is full.

Check connection to pigtail

and wall.

Contact Service Center.

Reset breaker.

Contact Service Center.

Empty the recovery tank.

Discharge pump does not

operate.

Unplugged cord.

Faulty switch or loose wiring.

Tripped building circuit

breaker.

Defective pump.

Recovery tank is not full

enough.

Check connection to pigtail

and wall.

Contact Service Center.

Reset breaker.

Contact Service Center.

Discharge pump will turn on

when there’s enough water in

the recovery tank.

Amount of discharge water

dwindles Worn impeller. Contact Service Center.

Pressure pump does not

operate or has low pressure.

Unplugged cord.

Faulty switch or loose wiring.

Tripped building circuit

breaker.

Defective pump.

Tripped pump circuit breaker.

Check connection to pigtail

and wall.

Contact Service Center.

Reset breaker.

Contact Service Center.

Reset breaker on pump.

TROUBLESHOOTING

11

OPTIONAL ACCESSORIES NOT INCLUDED

Wet/Dry Vac Wand

#WD29 (2 required)

Pressure

Washer

Gun #X1470

Wonder Wand™

1000 p.s.i. 3 Jet

#WW1000

Wet/Dry Vac

Tool #WD30A

Viper Renew

for restorative

cleaning #VR4

Viper Venom

for routine

cleaning #VV4

7” Spinner Hand

Tool #HP7

A Tacony Company

3101 Wichita Court • Ft. Worth, TX 76140-1755

1-800-880-2913 • Fax: 1-817-551-0719 • www.Powr-Flite.com

For warranty information go to www.Powr-Flite.com

PF1200RT-MAN 05/2021

Other manuals for PF1200RT

1

Table of contents

Other Powr-Flite Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Bonsai Zentrum

Bonsai Zentrum 2419 Instructions for use

Homelite

Homelite UT80522G Operator's manual

Hotsy

Hotsy 1200 Series Operator's manual

Craftsman

Craftsman 580.752580 Operator's manual

Parkside

Parkside PHD 110 C1 Translation of the original instructions

Generac Power Systems

Generac Power Systems 1042-2 owner's manual